Powerful Magnet for Lifting Steel Plates - High Efficiency & Reliability

The Rise of Magnets for Lifting Steel Plates

In the realm of industrial operations, the efficient handling of heavy materials such as steel plates is crucial. One of the most revolutionary advancements in this field is the development of magnets specifically designed for lifting steel plates. These magnetic lifting devices have changed the way industries handle these heavy loads, offering a safer and more efficient alternative to traditional lifting methods.

The Rise of Magnets for Lifting Steel Plates

Electromagnetic lifters, in particular, are a popular choice in many settings due to their flexibility and power control. These devices can be activated and deactivated with a simple switch, allowing operators to quickly attach or release steel plates as needed. The ability to control the lifting process electronically adds an extra layer of safety, as it minimizes the risk of the load slipping or falling.

magnet for lifting steel plate

Permanent magnetic lifters, on the other hand, do not require external power, making them ideal for use in environments where electricity may not be readily available. These magnets rely on the natural magnetic strength of their materials to hold loads securely. Their compact size and lightweight design make them easy to transport and operate, further enhancing their appeal in various industrial applications.

The versatility of magnetic lifters extends beyond mere lifting. They can be used not only for moving steel plates but also for transporting pipes, sheets, and other ferromagnetic materials. In warehouses, manufacturing facilities, construction sites, and recycling operations, these devices play a vital role in optimizing workflow and increasing productivity.

Environmentally, magnetic lifting systems contribute to sustainability initiatives. By reducing the need for synthetic lifting ropes and chains that require replacement and maintenance, these magnets lower the carbon footprint associated with lifting operations. Moreover, their ability to minimize the risk of workplace accidents aligns with modern safety standards, promoting a safer working environment.

In conclusion, magnets for lifting steel plates represent a significant advancement in industrial handling technology. Their efficient, safe, and environmentally friendly operation qualifies them as an essential tool in various sectors. As industries continue to evolve and seek innovative solutions for material handling challenges, the reliance on magnetic lifting systems is expected to grow. This shift not only benefits companies through enhanced productivity but also ensures a safer working environment for employees, emphasizing the importance of integrating advanced technologies in today's industrial landscape. The future holds immense potential for further innovations in magnetic lifting, opening new avenues for efficiency and safety in heavy lifting operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

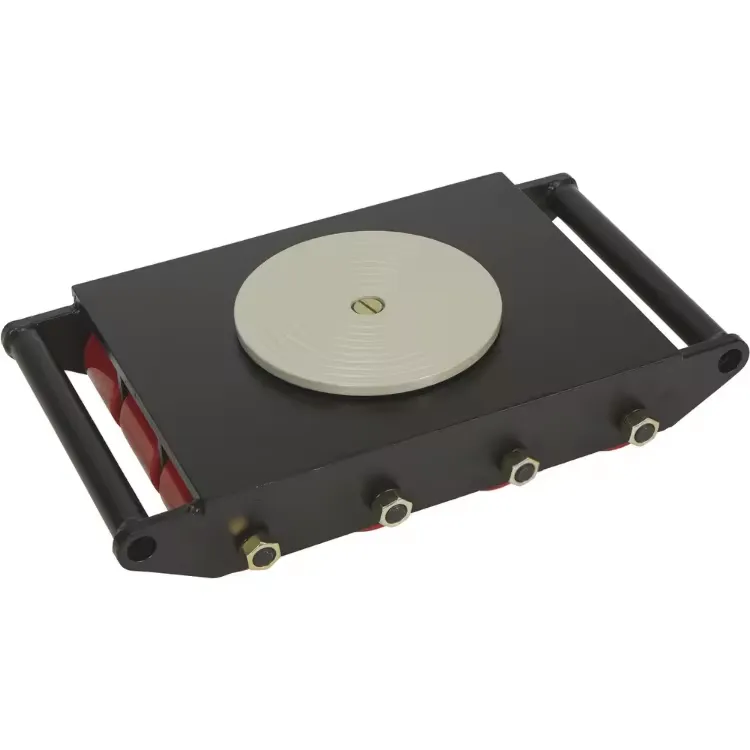

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025