Jan . 28, 2025 04:14

Back to list

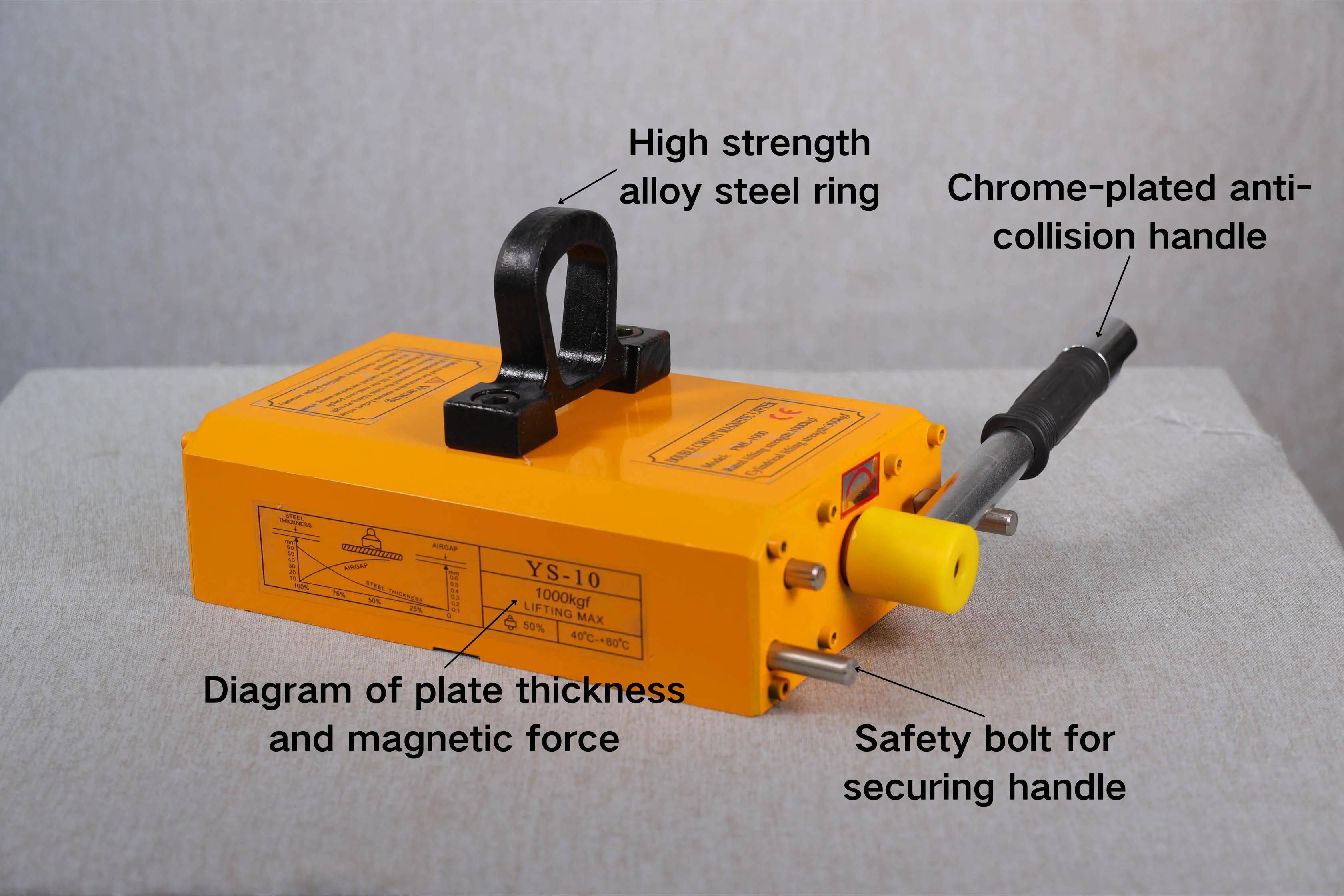

pml 10 lifting magnet

Magnetic lifting blocks have become indispensable tools across a range of industries, revered for their ability to handle heavy loads with precision and safety. This innovation has transformed the way industries approach material handling, offering a combination of efficiency and reliability that traditional methods simply cannot achieve. In this article, we delve into the intricacies of magnetic lifting blocks, exploring their applications, advantages, and the expertise required for their optimal use.

Authoritativeness in the field of magnetic lifting blocks is often established by manufacturers that adhere to stringent industry standards. Ensuring that lifting blocks are manufactured to specifications such as CE and ISO certifications provides users with the assurance of quality and reliability. Choosing a credible supplier that offers comprehensive support and warranty options further increases the trustworthiness of these devices. Several case studies highlight the transformative impact of magnetic lifting blocks across different sectors. In the shipbuilding industry, for example, the ability to move heavy steel plates with precision allows for more accurate construction, saving time and improving the quality of the structures. Meanwhile, in the automotive sector, these lifting solutions enhance the assembly of vehicles by enabling the quick and safe transportation of metal components. Trustworthiness is assured when companies prioritize regular maintenance and inspection of their lifting equipment. Even the most robust magnetic lifter requires periodic checks to ensure that it operates correctly and safely. Routine maintenance protocols, such as checking for surface wear and ensuring the magnet's strength has not diminished, are essential practices for maintaining trust in these powerful lifting tools. In conclusion, magnetic lifting blocks serve as an exemplar of how technology can enhance industrial operations. Their adoption reflects a commitment to efficiency, safety, and innovation. Firms that understand the capabilities and limitations of magnetic lifters are positioned to harness their benefits fully, thus driving productivity and reinforcing their market position. As industries continue to evolve, magnetic lifting blocks will undoubtedly remain a cornerstone of modern material handling solutions, exemplifying the perfect blend of engineering prowess and practical application.

Authoritativeness in the field of magnetic lifting blocks is often established by manufacturers that adhere to stringent industry standards. Ensuring that lifting blocks are manufactured to specifications such as CE and ISO certifications provides users with the assurance of quality and reliability. Choosing a credible supplier that offers comprehensive support and warranty options further increases the trustworthiness of these devices. Several case studies highlight the transformative impact of magnetic lifting blocks across different sectors. In the shipbuilding industry, for example, the ability to move heavy steel plates with precision allows for more accurate construction, saving time and improving the quality of the structures. Meanwhile, in the automotive sector, these lifting solutions enhance the assembly of vehicles by enabling the quick and safe transportation of metal components. Trustworthiness is assured when companies prioritize regular maintenance and inspection of their lifting equipment. Even the most robust magnetic lifter requires periodic checks to ensure that it operates correctly and safely. Routine maintenance protocols, such as checking for surface wear and ensuring the magnet's strength has not diminished, are essential practices for maintaining trust in these powerful lifting tools. In conclusion, magnetic lifting blocks serve as an exemplar of how technology can enhance industrial operations. Their adoption reflects a commitment to efficiency, safety, and innovation. Firms that understand the capabilities and limitations of magnetic lifters are positioned to harness their benefits fully, thus driving productivity and reinforcing their market position. As industries continue to evolve, magnetic lifting blocks will undoubtedly remain a cornerstone of modern material handling solutions, exemplifying the perfect blend of engineering prowess and practical application.

Next:

Latest news

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025