magnetic lifting block

The Advancements and Applications of Magnetic Lifting Blocks

In the realm of material handling and logistics, magnetic lifting blocks have emerged as a groundbreaking solution, redefining how industrial operations manage heavy loads. Utilizing powerful magnets, these innovative devices facilitate the lifting and transport of ferrous materials, streamlining operations while enhancing safety and efficiency. In this article, we will explore the mechanics behind magnetic lifting blocks, their various applications, and the advantages they offer over traditional lifting methods.

Understanding Magnetic Lifting Blocks

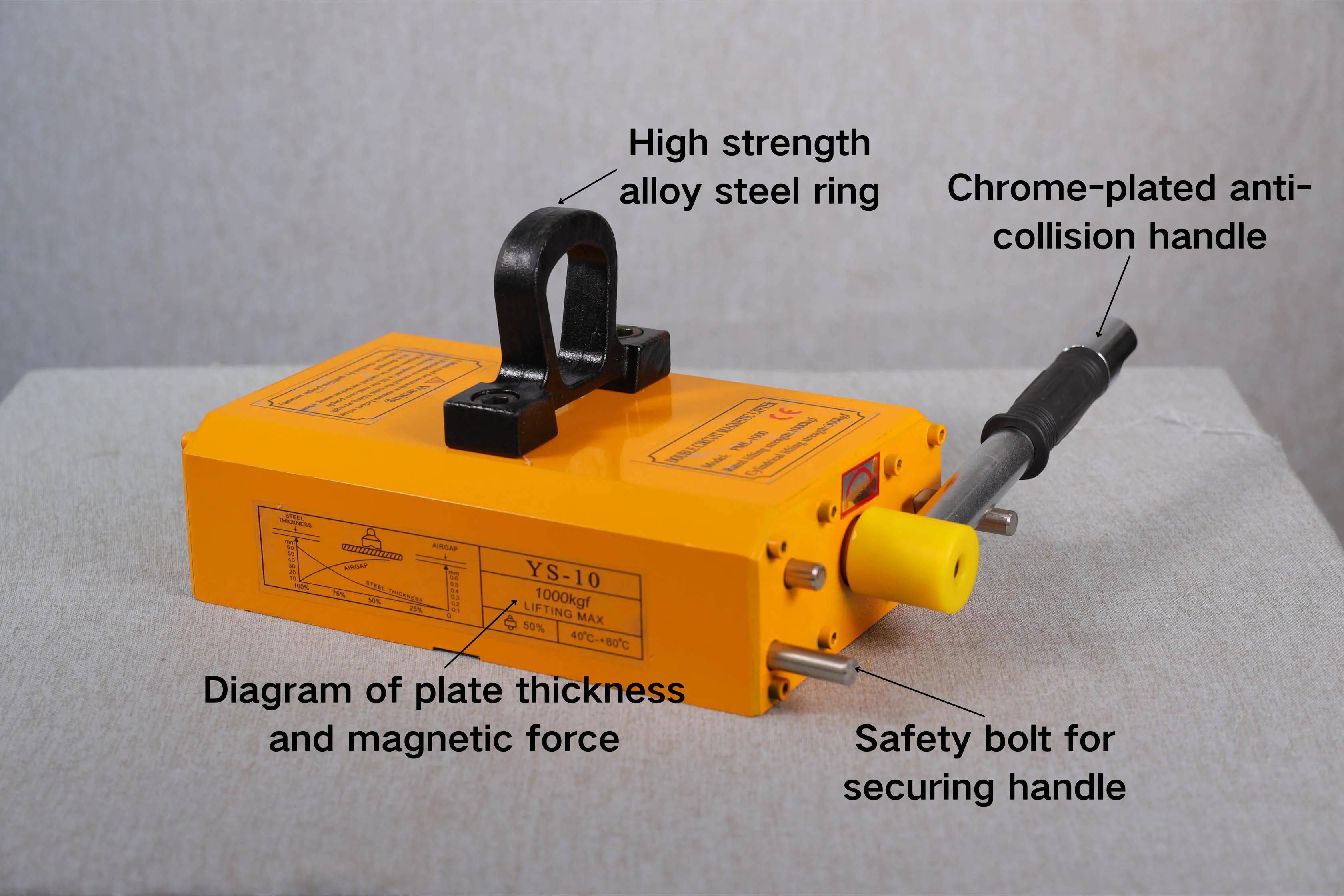

A magnetic lifting block operates on the principle of magnetism, employing either permanent magnets or electromagnets to grip metallic objects securely. The design of these blocks often features a robust casing that houses the magnetic source, along with a control mechanism that allows users to engage or disengage the magnetic force as needed.

Permanent magnets rely on magnetic materials that maintain their magnetization, providing a constant hold without the need for power. On the other hand, electromagnets generate magnetism through electrical current, allowing for adjustable strength and control over the lifting process. The later option is often favored in applications requiring variable lifting capacities or where the weight of the load changes frequently.

Applications Across Industries

The flexibility and efficiency of magnetic lifting blocks have made them indispensable across various industries. In manufacturing, these devices are used to lift and transport metal sheets, components, and assemblies, reducing the risk of damage typically associated with manual handling or using chains and slings. Their rapid deployment and quick disengagement feature also minimize downtime during production cycles.

In the construction sector, magnetic lifting blocks are utilized for moving steel beams and structures. Their ability to lift heavy loads safely contributes to greater efficiency on job sites. Moreover, in recycling facilities, these blocks can easily segregate and manage scrap metal, promoting a more streamlined recycling process.

The automotive industry benefits significantly from magnetic lifting technology

. Whether it's handling body panels during production or moving heavy components during assembly, magnetic lifting blocks reduce labor intensity and enhance precision. Additionally, they contribute to creating a safer work environment by decreasing the chances of accidents linked to manual lifting.magnetic lifting block

Advantages of Magnetic Lifting Blocks

One of the most compelling advantages of magnetic lifting blocks is their efficiency. Traditional lifting methods often require multiple personnel or complex rigging systems, which can be time-consuming and increase the potential for errors. Magnetic lifting blocks, however, can be operated by a single worker, significantly improving productivity.

Furthermore, the risk of damage to lifted materials is considerably reduced. The even distribution of magnetic force ensures that objects are held securely throughout the lifting process, minimizing the chance of drops or misalignments. This is especially critical when dealing with fragile or high-value items.

Safety is another crucial benefit. With a robust design and limited moving parts, magnetic lifting blocks reduce the likelihood of mechanical failure. Additionally, their ability to lift without contact means that workers can maintain a safe distance from the load, further diminishing the risk of injury.

Integration with automation is also a notable aspect of modern magnetic lifting blocks. Many devices can be paired with robotic systems, allowing for sophisticated automated operations that increase throughput while preserving safety standards. This synergy between human and robotic handling is becoming increasingly important in the era of Industry 4.0.

The Future of Magnetic Lifting Technology

As technology continues to advance, the future of magnetic lifting blocks looks promising. Innovations in materials science, particularly in the development of stronger and more efficient magnets, are expected to enhance lifting capacities and overall performance. Moreover, ongoing research into smart technologies may lead to further enhancements, including real-time monitoring and predictive analytics to ensure optimal operation and maintenance.

In conclusion, magnetic lifting blocks have revolutionized the way industries handle heavy materials. Their ability to improve efficiency, safety, and precision positions them as a cornerstone technology in the modern industrial landscape. As advancements continue to unfold, embracing these innovations will undoubtedly lead to even more refined processes and a reimagined approach to material handling.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025