magnetic lifting handle

The Benefits and Innovations of Magnetic Lifting Handles

In the realm of material handling and logistics, efficiency and safety are paramount. One innovation that has significantly enhanced these aspects is the magnetic lifting handle. This ingenious tool not only streamlines the lifting process but also offers a myriad of advantages that traditional lifting methods simply cannot match.

What are Magnetic Lifting Handles?

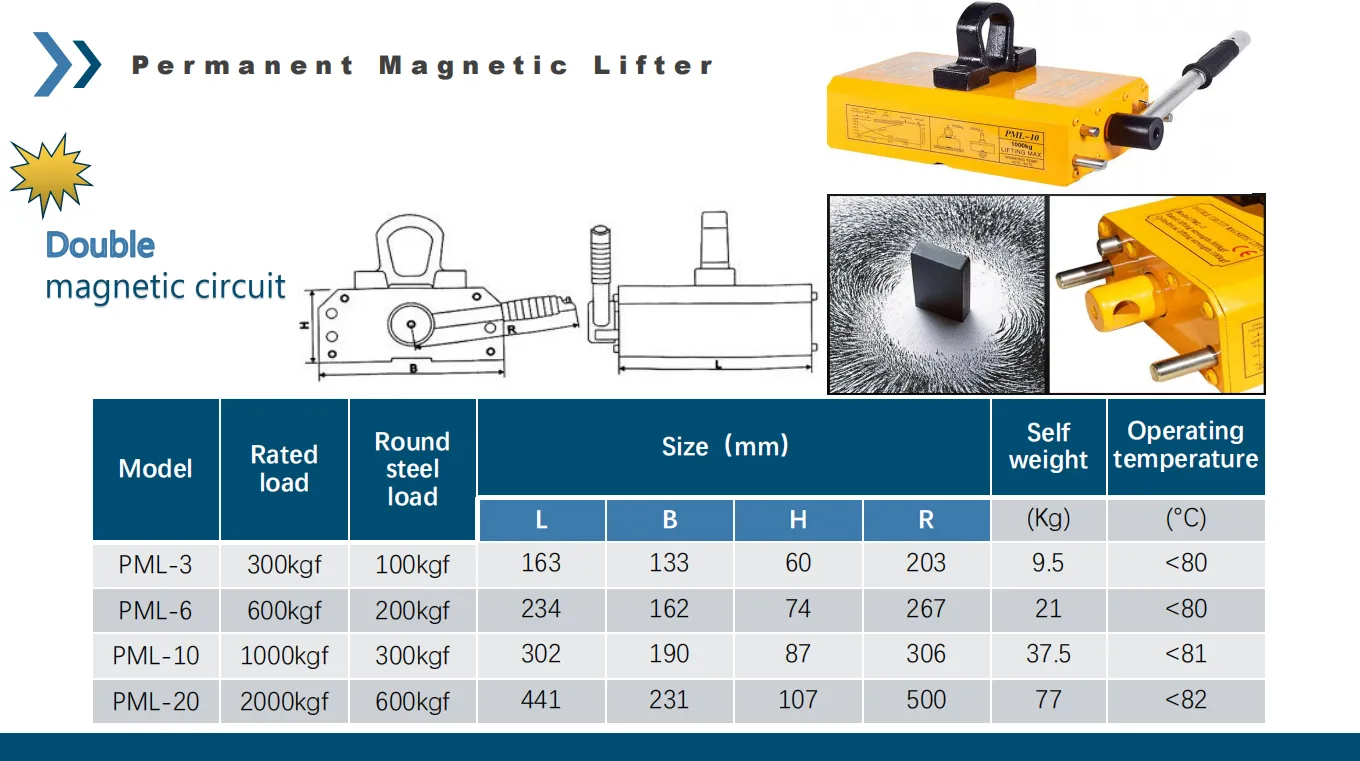

Magnetic lifting handles are specialized tools designed to aid in the safe and efficient lifting of heavy items. They utilize powerful magnets to securely attach to ferromagnetic materials, providing a reliable grip during lifting operations. Typically made from durable materials and coated to protect against wear and tear, these handles come in various sizes and strengths to cater to different lifting requirements.

The Advantages of Magnetic Lifting Handles

1. Enhanced Safety One of the most significant advantages of magnetic lifting handles is the enhancement of safety in the workplace. Traditional lifting methods often involve straps, chains, or even human force, which can lead to accidents and injuries if not executed properly. Magnetic lifting handles minimize the risk of dropping heavy items as they provide a firm, secure attachment. This is especially crucial in environments where workers are handling heavy machinery, steel plates, or other substantial components.

2. Efficiency and Productivity Time is money in any industrial setting, and magnetic lifting handles can dramatically cut down the time spent on lifting and transporting materials. The quick attachment and release capabilities mean that workers can move items faster, reducing downtime and increasing overall productivity. Moreover, they can accommodate a variety of shapes and surface types, making them versatile for different situations.

3. Ease of Use Unlike traditional lifting devices, magnetic lifting handles are user-friendly. They typically require minimal training to operate, allowing workers to quickly adapt to their use. The simplicity of magnetic attachment means that even one person can easily lift heavy loads without the need for additional manpower. This not only reduces labor costs but also optimizes the workflow.

magnetic lifting handle

4. Cost-Effectiveness Investing in magnetic lifting handles is a cost-effective solution for businesses. The durability and longevity of these handles mean they can withstand heavy use, reducing the need for frequent replacements. Furthermore, the increased efficiency and safety can lead to lower insurance premiums and reduced worker compensation costs due to fewer accidents.

5. Environmentally Friendly Magnetic lifting handles are often made from recyclable materials, making them an environmentally friendly choice. In today’s eco-conscious market, businesses are increasingly seeking ways to reduce their carbon footprint, and utilizing such tools can contribute to a greener operation.

Considerations for Use

While there are numerous benefits to using magnetic lifting handles, it is essential to consider a few factors for optimal performance. First, the surface of the material being lifted must be ferromagnetic for the magnets to work effectively. Additionally, operators should always check for any surface irregularities or contaminants, like rust or oil, that might hinder magnetic adhesion.

Furthermore, understanding the weight limits of the magnetic lifting handle in use is crucial. Overloading can lead to equipment failure and accidents. Manufacturers usually provide clear guidelines regarding weight capacities, and adherence to these specifications is vital.

Conclusion

As industries continue to evolve, the need for innovative solutions to enhance productivity and safety becomes increasingly important. Magnetic lifting handles represent a significant leap forward in material handling technology. With their combination of strength, safety, and efficiency, they are transforming the way heavy materials are managed in various sectors. By integrating these tools into operational processes, companies can not only improve their workflow but also protect their workforce, making them a valuable asset in today's competitive marketplace.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025