magnetic lifting hook

Understanding Magnetic Lifting Hooks Applications and Advantages

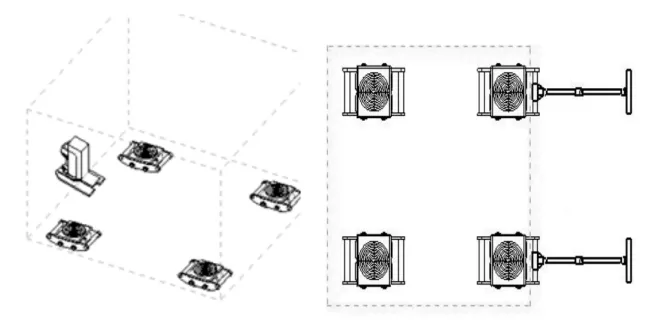

Magnetic lifting hooks are innovative tools designed for handling ferrous materials in various industrial settings. These devices are primarily used for lifting and transporting heavy loads, providing a safer and more efficient method of material handling. With the advancement of technology, magnetic lifting hooks have become increasingly popular due to their versatility, durability, and ease of use. In this article, we will explore the applications, advantages, and safety considerations associated with magnetic lifting hooks.

Applications of Magnetic Lifting Hooks

Magnetic lifting hooks find extensive applications across several industries, including manufacturing, construction, and shipping. In manufacturing plants, they are commonly used for lifting heavy steel sheets, coils, and billets. This makes them indispensable in industries like automotive, aerospace, and metal fabrication, where heavy materials are handled regularly.

In construction, magnetic lifting hooks facilitate the movement of iron beams and other structural components, streamlining the workflow on job sites. They simplify the lifting process by allowing cranes and hoists to pick up materials quickly and securely, which reduces the risk of accidents and improves productivity.

In logistics and shipping, these hooks are employed to load and unload containers and machinery. The ability to lift multiple items at once and the secure grip provided by magnetic forces make them invaluable for operations that require efficiency and speed.

Advantages of Magnetic Lifting Hooks

One of the primary advantages of magnetic lifting hooks is their simplicity of operation. Unlike traditional lifting equipment that often requires complex mechanisms or manual force, magnetic lifting hooks use magnetic forces to grip ferrous materials. Operators can easily control the lifting process with a simple on/off switch, which significantly reduces the amount of training required for personnel to operate these systems.

magnetic lifting hook

Moreover, magnetic lifting hooks offer a high level of safety. Traditional lifting methods often involve chains and slings that can slip or break, posing risks of injury to workers. In contrast, magnetic hooks create a solid bond with the material being lifted, minimizing the chances of accidental drops. Many modern magnetic hooks are equipped with safety features, such as power loss protection, which ensures that the magnet stays engaged even in the event of an electrical failure.

Another significant advantage is their versatility. Magnetic lifting hooks are available in various sizes and lifting capacities, making it easy to find a model suitable for different tasks. Additionally, they can be used on various surfaces, including flat, curved, and irregular shapes. This adaptability makes them an excellent choice for a wide range of applications.

Safety Considerations

While magnetic lifting hooks offer numerous benefits, safety should always be the primary concern when using them. Operators must ensure that the material being lifted is ferrous, as these hooks will not work effectively with non-ferrous materials like aluminum or copper.

It is also crucial to assess the surface condition of the material. Dirty or rusty surfaces can affect the magnetic grip, leading to potential hazards during lifting. Routine inspections are necessary to ensure that both the hook and the materials are in good condition.

Furthermore, operators should always follow the manufacturer's guidelines regarding the weight limits and usage specifications of the magnetic lifting hooks. Overloading the hook can lead to equipment failure and serious accidents.

Conclusion

Magnetic lifting hooks represent a significant advancement in material handling technology. Their efficiency, ease of use, and safety features make them ideal for various industrial applications. As industries continue to evolve and demand more efficient and safer lifting solutions, the popularity and usage of magnetic lifting hooks are expected to grow. By understanding their applications, advantages, and the necessary safety protocols, businesses can effectively integrate these tools into their operations, ultimately enhancing productivity and ensuring a safer workplace.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025