Magnetic Sheet Metal Lifter for Efficient Handling and Transport Solutions

The Magnetic Sheet Metal Lifter A Revolutionary Tool for Metal Handling

In the world of manufacturing and construction, efficiency and safety are paramount. One of the innovative tools that have emerged to enhance these factors is the magnetic sheet metal lifter. This device has been designed to streamline the handling and transportation of metal sheets, offering significant advantages over traditional methods.

Understanding Magnetic Sheet Metal Lifters

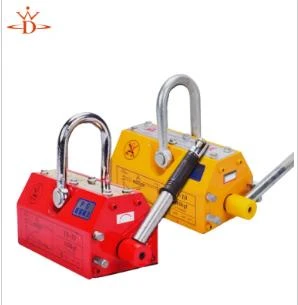

A magnetic sheet metal lifter is a device that utilizes powerful magnets to lift and move ferromagnetic materials such as steel sheets. Unlike conventional lifting methods, which often rely on slings, clamps, or hooks, magnetic lifters provide a simple yet effective solution. They operate through the principles of magnetism, enabling quick and secure handling without damaging the material or compromising safety.

Typically made of robust materials to withstand industrial conditions, these lifters are equipped with either permanent magnets or electromagnets. Permanent magnets are always magnetic, allowing for immediate use without the need for power. On the other hand, electromagnets require an electrical supply to generate a magnetic field, offering the benefit of adjustable lifting power.

Advantages of Using Magnetic Lifters

1. Enhanced Safety One of the primary benefits of using a magnetic sheet metal lifter is the improved safety it provides. Traditional methods often involve manual handling or the risk of objects slipping from clamps. With magnetic handling, the chance of accidents due to slipping or dropping items is significantly reduced.

2. Increased Efficiency Lifting and moving heavy metal sheets can be labor-intensive and time-consuming. Magnetic lifters allow for quick attachment and release, reducing the time spent on each task. Workers can maneuver metal sheets with minimal effort, resulting in faster project completion times and increased productivity.

magnetic sheet metal lifter

3. Reduced Labor Costs By minimizing the number of personnel required for lifting operations, companies can reduce labor costs. Additionally, the ergonomic advantages of using magnetic lifters mean less physical strain on workers, potentially lowering the incidence of work-related injuries.

4. Versatility Magnetic sheet metal lifters are not limited to specific tasks. They can handle various sizes and thicknesses of metal sheets, making them suitable for different applications across industries, including manufacturing, construction, metalworking, and warehousing.

5. Surface Protection Unlike mechanical lifting methods that can mar or damage the surface of the sheets, magnetic lifters provide a gentle grip. This is particularly important for finished products where surface integrity is essential.

Applications in Various Industries

The versatility of magnetic sheet metal lifters makes them valuable in multiple sectors. In manufacturing environments, they facilitate the movement of large metal sheets from storage to production lines. In construction, they simplify lifting operations on job sites, allowing for safe placement of materials. They are also crucial in metal fabrication shops, enabling more efficient assembly and welding processes.

Additionally, in the warehousing sector, these lifters streamline the storage and retrieval of metal products, contributing to more organized and efficient inventory management.

Conclusion

The magnetic sheet metal lifter represents a significant advancement in the field of material handling. With their numerous advantages—enhanced safety, increased efficiency, reduced labor costs, versatility, and surface protection—these devices have become essential tools in various industries. As technology continues to evolve, the applications and capabilities of magnetic lifters are likely to expand, further transforming metal handling processes. For businesses looking to improve their operations, investing in magnetic sheet metal lifters is undoubtedly a step in the right direction. As the industry becomes more focused on automation and safety, these lifters will continue to play a vital role in shaping the future of manufacturing and construction.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025