Magnetic Metal Lifters for Efficient Material Handling Solutions

The Benefits and Applications of Magnetic Sheet Metal Lifters

In the ever-evolving world of manufacturing and construction, efficient handling of materials is vital for maintaining productivity and ensuring safety. One innovative tool that has made significant contributions to these sectors is the magnetic sheet metal lifter. These devices offer a powerful yet simple solution for lifting and transporting heavy sheet metal materials with ease.

Magnetic sheet metal lifters utilize powerful magnets to grip and lift ferromagnetic materials, primarily iron and steel. The design of these lifters typically incorporates a set of permanent magnets combined with a mechanical lever or switching mechanism, which allows users to engage or disengage the magnetic grip with minimal effort. This ensures that workers can efficiently move heavy sheets without the need for cumbersome slings, chains, or hooks.

One of the most compelling advantages of magnetic lifters is the significant reduction in manual handling, which can pose serious injury risks to workers. Traditionally, lifting heavy sheet metal required several personnel or heavy machinery, increasing the chances of accidents and workplace injuries. By integrating magnetic lifters into operations, companies not only enhance safety but also streamline processes, allowing for quicker turnaround times on projects.

Moreover, magnetic sheet metal lifters are designed with efficiency in mind. They can easily lift sheets weighing hundreds of pounds with minimal strain on the operator. This efficiency translates to lower operational costs, as fewer workers are needed for lifting tasks, and the time saved in handling can lead to increased productivity. Businesses can achieve more in less time, ultimately boosting profitability.

In terms of versatility, magnetic sheet metal lifters are available in various sizes and lifting capacities. Whether a project involves thin sheets of stainless steel or thick, heavy plates of iron, there is a magnetic lifter suited to meet specific requirements. Additionally, many lifters are designed to accommodate various sheet sizes and shapes, making them suitable for multiple applications across different industries, including automotive, aerospace, construction, and metal fabrication.

magnetic sheet metal lifter

Another notable benefit is the ease of use. Magnetic sheet metal lifters require minimal training to operate a feature that is especially advantageous in environments with high turnover rates. Workers can quickly learn how to use these tools efficiently and safely, reducing the time and resources required for training programs.

Environmental factors are also worth considering. Magnetic lifters typically consume minimal energy, especially when compared to electric or hydraulic lifting systems. This can lead to reduced operational costs and a smaller carbon footprint, making magnetic sheet metal lifters an environmentally friendly choice for conscientious manufacturers.

In addition to lifting and transporting, these devices can also aid in positioning and aligning sheet metal during assembly processes. Their ability to hold materials securely allows operators to achieve precise placements without needing additional equipment, further enhancing productivity and the quality of work.

However, it is crucial to ensure that workers understand the limitations of magnetic lifters. For instance, magnetic strength can be affected by surface conditions and the presence of debris. Therefore, maintaining a clean work environment and regularly inspecting the equipment is essential for optimal performance and safety.

In conclusion, magnetic sheet metal lifters represent a significant advancement in the handling of heavy materials within manufacturing and construction industries. By prioritizing safety, efficiency, versatility, and environmental consciousness, these lifting tools empower businesses to optimize their operations and foster a safer workplace. As industries continue to evolve, the importance of innovative solutions like magnetic lifters will only become more pronounced, solidifying their place as essential tools in modern manufacturing and construction practices.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

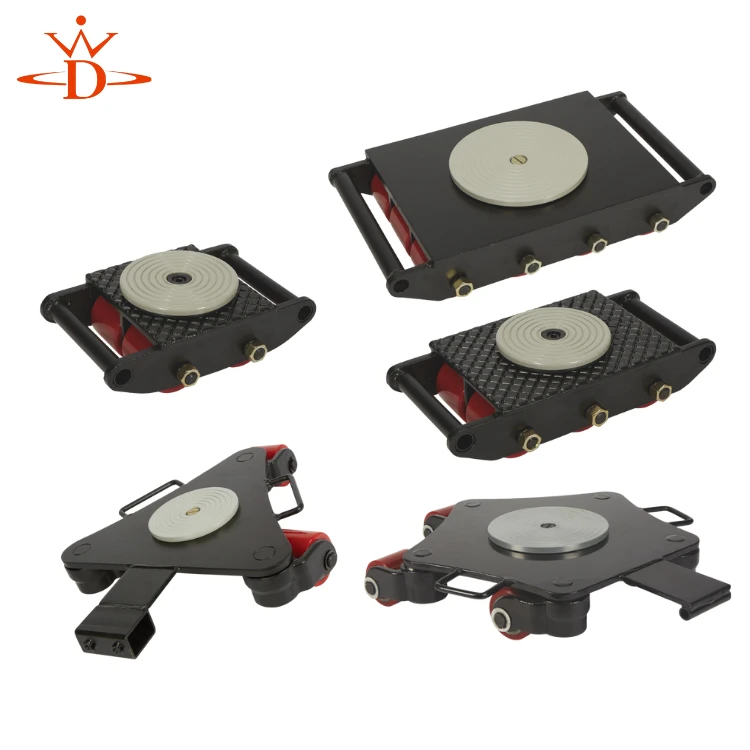

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025