movable gantry

The Movable Gantry Revolutionizing Industrial Material Handling

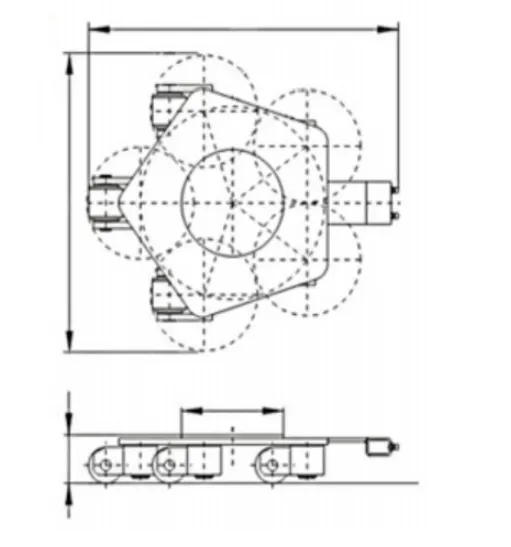

In the realm of industrial logistics and material handling, the movable gantry has emerged as a vital innovation, significantly enhancing efficiency and convenience across various sectors. This type of crane system is characterized by its ability to traverse along a set of tracks, allowing for maximum flexibility when lifting and transporting heavy loads. Its design, which typically features two vertical supports and a horizontal beam (or gantry), makes it uniquely suited to address the challenges posed by static lifting systems.

One of the primary advantages of movable gantries is their versatility. They can be employed in manufacturing plants, warehouses, construction sites, and even shipyards. With the capacity to handle a wide variety of weights and sizes, they eliminate the need for specialized lifting equipment tailored to specific tasks. This capability is crucial in environments where multiple distinct operations occur, as it allows a single gantry system to adapt to different tasks simply by adjusting its setup.

Moreover, the mobility of these gantries enhances operational efficiency. Traditional gantry cranes often operate in fixed positions, which can lead to delays and increased labor costs when moving materials over a large area. The movable gantry, on the other hand, allows for rapid repositioning, reducing downtime and enabling smoother workflows. This feature is particularly beneficial in high-paced production environments, where time is a critical factor.

movable gantry

Safety is another paramount concern in industrial settings. Movable gantries are designed with safety mechanisms that protect both operators and bystanders. Features such as overload protection, automatic stopping systems, and remote controls enhance operational security while minimizing the risk of accidents. Additionally, by substituting manual lifting with a movable gantry, the physical strain on workers is greatly reduced, promoting a healthier workplace and lowering the likelihood of injuries.

Environmental sustainability is also becoming increasingly important in industrial operations. Movable gantries often feature designs that minimize energy consumption. Many modern systems are equipped with electric drives rather than diesel-powered engines, promoting cleaner and more efficient material handling processes. This not only aligns with global green initiatives but also reduces operational costs over the long term.

In conclusion, the movable gantry serves as a cornerstone of modern industrial operations, marrying efficiency, versatility, safety, and sustainability. Its ability to adapt to various tasks while ensuring safe and swift material handling makes it an indispensable tool in today’s fast-paced and ever-evolving industries. As technology continues to advance, we can expect further enhancements in movable gantry systems, paving the way for even more innovative solutions that improve productivity and operational efficiency across the globe.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025