Versatile Gantry Crane Hoist for Efficient Material Handling Solutions

The Movable Gantry Crane Hoist A Modern Engineering Marvel

In the realm of heavy lifting equipment, few machines are as versatile and efficient as the movable gantry crane hoist. These engineering marvels are integral to various industries, from shipbuilding and construction to manufacturing and logistics. Their design and functionality make them indispensable in handling heavy loads with precision, safety, and efficiency.

Understanding the Movable Gantry Crane Hoist

A movable gantry crane hoist consists of a bridge structure supported by two or four legs that can be wheeled along a track. The hoisting mechanism is usually mounted on the bridge, which allows it to move horizontally, making it well-suited for various applications. Unlike traditional overhead cranes, movable gantry cranes offer the flexibility to be positioned anywhere in the workspace, making them ideal for temporary setups or locations where overhead structures are not feasible.

Key Components and Features

The primary components of a movable gantry crane hoist include

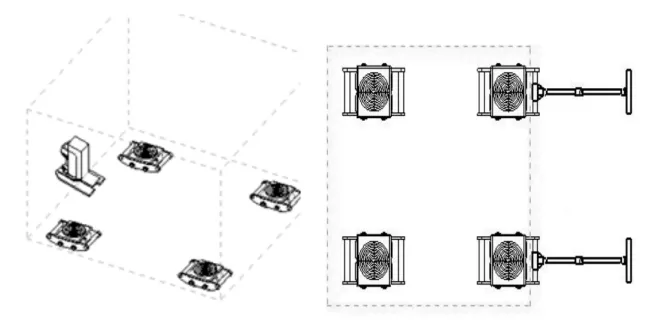

1. Gantry Structure The main frame, typically made from steel, provides stability and strength. The design can vary from single leg to double leg setups, depending on the required lift capacity and workspace constraints.

2. Hoisting Mechanism This includes a winch or electric hoist that raises and lowers the load. Modern hoists are equipped with advanced features such as variable speed control, which enhances operational efficiency.

3. Wheels and Tracks Most movable gantry cranes are mounted on wheels that glide along tracks. This mobility allows the crane to be relocated easily without requiring a permanent installation.

5. Safety Features Modern gantry cranes are imbued with safety features such as limit switches, emergency stop buttons, and overload protection mechanisms to ensure safe operation.

movable gantry crane hoist

Applications Across Industries

The versatility of movable gantry cranes allows them to be utilized in various sectors. In construction, they are often used to lift steel beams and prefabricated components, significantly speeding up the building process. In shipbuilding, these cranes facilitate the assembly and maintenance of vessels, allowing for the movement of heavy parts in confined spaces.

In manufacturing, they can be seen on assembly lines where heavy machinery needs to be moved or installed. Logistics companies use them in warehouses to load and unload heavy items from trucks or containers, enhancing efficiency in operations.

Advantages of Movable Gantry Crane Hoist

1. Flexibility The ability to move the crane easily throughout a workspace allows businesses to adapt to changing operational needs without being tethered to a fixed apparatus.

2. Cost-Effective Compared to traditional overhead cranes, movable gantry cranes provide a more economical solution for companies requiring temporary lifting solutions, as they often have lower initial costs and maintenance expenses.

3. Ease of Use With user-friendly controls, even operators with minimal training can quickly learn to operate a movable gantry crane hoist, thus reducing onboarding time and improving productivity.

4. Safe Work Environment By providing a stable and controlled method for lifting heavy loads, movable gantry cranes significantly reduce the risks associated with manual lifting and handling.

Conclusion

The movable gantry crane hoist stands as a testament to modern engineering, embodying flexibility, safety, and efficiency. Its ability to adapt to various environments and applications makes it an essential tool across many industries. As technology continues to advance, we can expect further innovations in crane design and functionality, which will undoubtedly enhance the capabilities of movable gantry cranes. Whether in a construction site, a factory, or a dockyard, these cranes remain at the forefront of heavy lifting solutions, exemplifying how engineering can facilitate progress and productivity in the industrial sector.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025