Jan . 23, 2025 05:34

Back to list

Dawei Machinery Mover 180° Rotation Type Macinery Mover 6000/8000/12000 Kgs.

Relocating large equipment is an intricately challenging task that surpasses ordinary transportation projects. The sheer scale, weight, and precision required necessitate specialized knowledge and tools. For businesses involved with heavy machinery, understanding the complexities of moving such equipment safely and efficiently is crucial. The following insights provide an in-depth exploration of the essential components that contribute to a successful relocation, establishing a roadmap for handling these mammoth tasks with expertise and assurance.

Temperature and weather conditions can critically affect the transportation of large equipment, particularly when moving sensitive machinery. Weather extremes may require additional protective measures, such as specialized covers or climate-controlled transportation, to prevent damage that could lead to costly repairs or operational downtimes. Regular monitoring and contingency strategies are imperative in preventing weather-induced complications. Communication is vitally important throughout the entire process. Keeping all stakeholders informed—from logistics teams and operators to the end users—ensures that any issues can be rapidly addressed, minimizing downtime. Transparency in communication also enables swift decision-making when unforeseen challenges arise, safeguarding the project timeline and budget. Establishing reliability and trustworthiness with clients depends on showcasing a strong safety history and consistently delivering on promises. Engage in continuous improvement practices, documenting each transport’s lessons learned to enhance service quality over time. Demonstrating a commitment to safety and efficacy fosters stronger client relationships and bolsters company reputation within the industry. Finally, understanding the client’s business needs and objectives goes beyond merely delivering equipment from one location to another. It involves aligning transportation solutions with their operational strategies, creating a move that serves not just logistical efficiency but also broader business goals. Providing tailored solutions not only amplifies client satisfaction but also elevates the service from a transactional interaction to a strategic partnership. By integrating these multifaceted aspects—comprehensive planning, regulatory knowledge, methodical transportation choices, skilled personnel, environmental considerations, and robust communication—a blueprint for moving large equipment is formulated. This path not only facilitates successful transportation but also reinforces a reputation for expertise and dependability within the industry, cementing relationships and building a foundation of trust and authority with every successful move.

Temperature and weather conditions can critically affect the transportation of large equipment, particularly when moving sensitive machinery. Weather extremes may require additional protective measures, such as specialized covers or climate-controlled transportation, to prevent damage that could lead to costly repairs or operational downtimes. Regular monitoring and contingency strategies are imperative in preventing weather-induced complications. Communication is vitally important throughout the entire process. Keeping all stakeholders informed—from logistics teams and operators to the end users—ensures that any issues can be rapidly addressed, minimizing downtime. Transparency in communication also enables swift decision-making when unforeseen challenges arise, safeguarding the project timeline and budget. Establishing reliability and trustworthiness with clients depends on showcasing a strong safety history and consistently delivering on promises. Engage in continuous improvement practices, documenting each transport’s lessons learned to enhance service quality over time. Demonstrating a commitment to safety and efficacy fosters stronger client relationships and bolsters company reputation within the industry. Finally, understanding the client’s business needs and objectives goes beyond merely delivering equipment from one location to another. It involves aligning transportation solutions with their operational strategies, creating a move that serves not just logistical efficiency but also broader business goals. Providing tailored solutions not only amplifies client satisfaction but also elevates the service from a transactional interaction to a strategic partnership. By integrating these multifaceted aspects—comprehensive planning, regulatory knowledge, methodical transportation choices, skilled personnel, environmental considerations, and robust communication—a blueprint for moving large equipment is formulated. This path not only facilitates successful transportation but also reinforces a reputation for expertise and dependability within the industry, cementing relationships and building a foundation of trust and authority with every successful move.

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

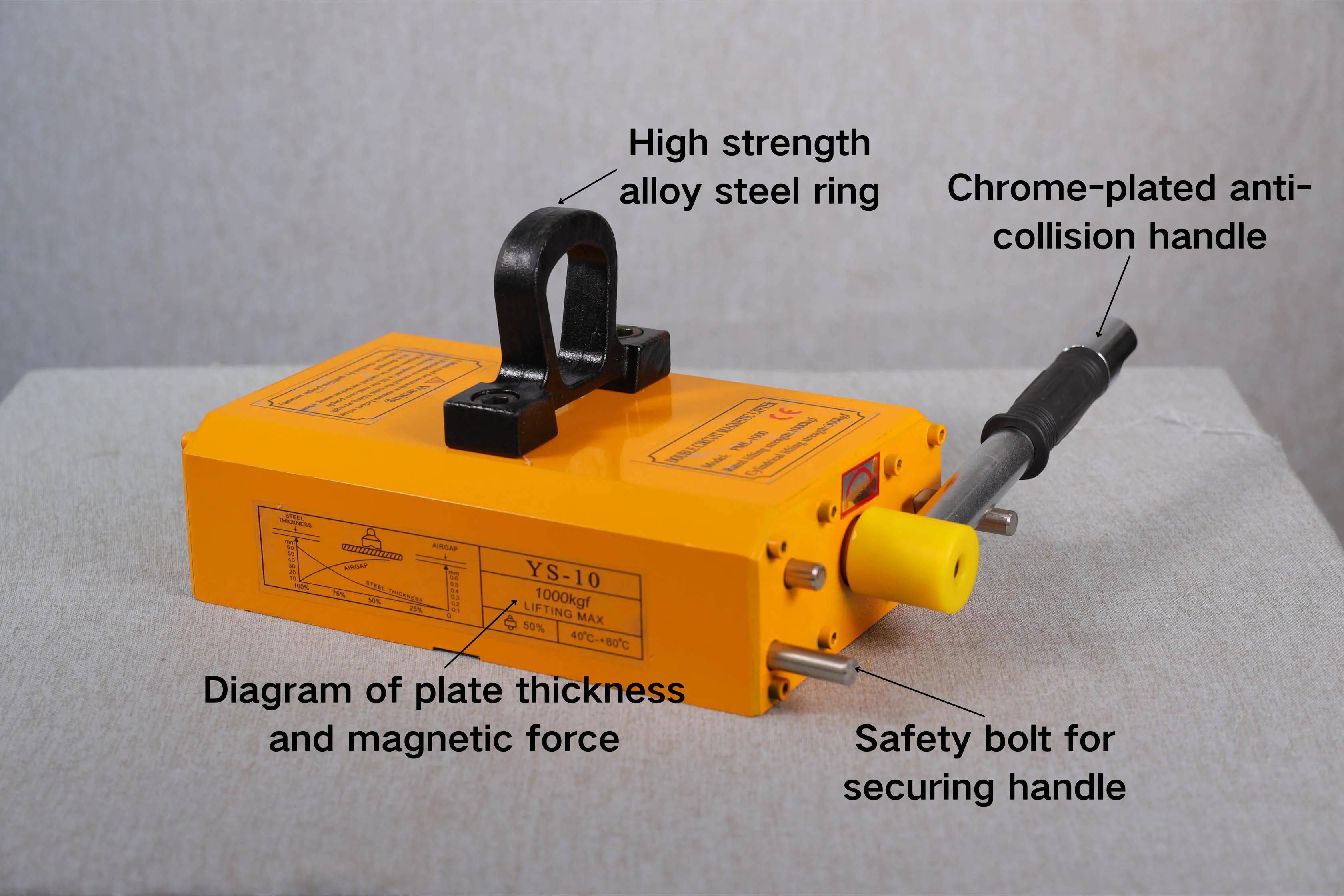

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025