moving heavy equipment with rollers

Moving Heavy Equipment with Rollers A Comprehensive Guide

Moving heavy equipment is a vital aspect of many industries, including construction, manufacturing, and logistics. When transporting large machinery, it’s crucial to consider the safety, efficiency, and accessibility of the moving process. One popular method for moving heavy equipment is using rollers, which can significantly facilitate the transportation of these colossal machines. In this article, we’ll explore the advantages, types, and best practices for using rollers in the movement of heavy equipment.

The Advantages of Using Rollers

Using rollers to move heavy equipment offers several advantages over traditional methods. Firstly, rollers reduce friction between the ground and the machinery being moved, making it easier to slide the equipment across various surfaces. This not only saves time but also requires less labor and energy, making the operation more efficient.

Secondly, rollers distribute the weight of the heavy equipment evenly, minimizing the risk of damage to floors or ground surfaces. This is particularly important in environments with sensitive flooring or in locations where the equipment may need to be moved frequently.

Finally, using rollers can enhance safety during the moving process. Manual lifting and moving can lead to injuries and accidents. Rollers allow for a more controlled movement, reducing the risk of worker accidents and equipment damage.

Types of Rollers

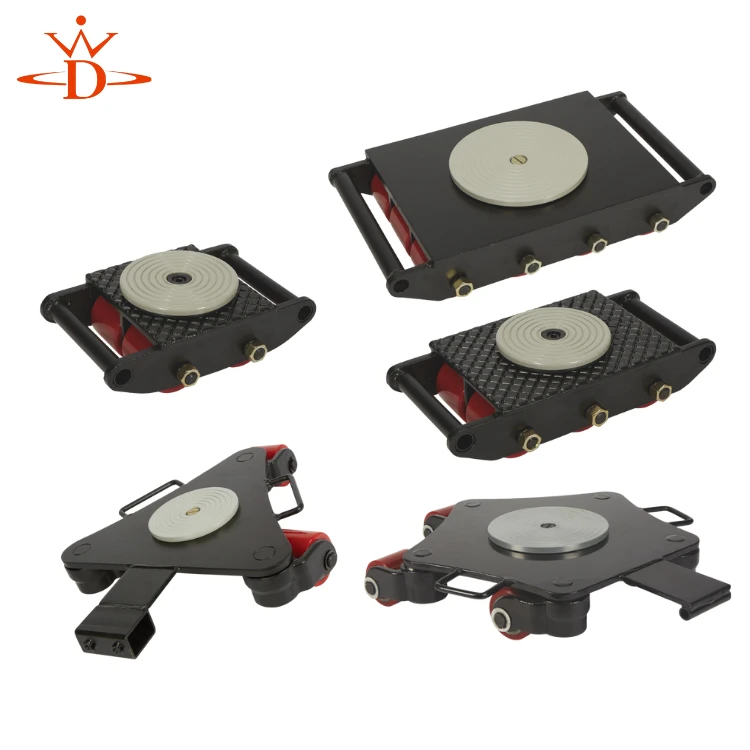

When it comes to moving heavy equipment, various types of rollers can be employed based on the nature of the task and the environment

1. Polyurethane Rollers These are designed for use on smooth surfaces and provide a high load capacity without damaging the flooring. They are ideal for indoor environments where heavy equipment needs to be moved frequently.

2. Steel Rollers For rougher terrains or heavier applications, steel rollers are perfect. They are durable and can withstand significant loads, making them suitable for outdoor construction sites.

3. Pneumatic Rollers These rollers have inflatable tires and can traverse over rough or uneven surfaces with ease. They are commonly used in the transportation of heavy equipment over long distances and in variable terrains.

moving heavy equipment with rollers

4. Rotating Rollers These rollers allow for more maneuverability and control, making them ideal for tight spaces or when precise positioning is required. They often come with locks to secure the equipment in place during the moving process.

Best Practices for Moving Heavy Equipment with Rollers

To ensure a safe and efficient moving process, there are best practices that should be followed when using rollers

1. Assess the Load Before commencing the move, assess the weight and dimensions of the equipment. This will help determine the type and number of rollers required.

2. Prepare the Pathway Clear the pathway of any obstructions or debris. Ensure that the surface is suitable for roller movement and will not cause any damage to the equipment or ground.

3. Use Appropriate Equipment Select rollers that can support the load without causing damage. Using inadequate rollers can lead to accidents and equipment failure.

4. Team Coordination Establish clear communication and roles among team members during the moving process. This ensures a coordinated effort, reducing the risk of accidents.

5. Monitor During Movement Keep an eye on the equipment as it is being moved. Ensure that the rollers are functioning correctly and that the load remains stable throughout the process.

6. Post-Move Inspection After the equipment has been successfully moved, conduct a thorough inspection to ensure that everything is intact and operational.

Conclusion

Moving heavy equipment with rollers is a practical, efficient, and safe method that can be utilized across various industries. By harnessing the benefits of rollers and following best practices, businesses can optimize their heavy transportation efforts. This not only enhances productivity but also ensures the safety of workers and the integrity of the equipment being transported. Whether you are in construction, manufacturing, or logistics, understanding how to effectively use rollers can significantly streamline your heavy equipment moving processes.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025