moving large machinery

Moving large machinery can be a demanding and complex task that requires careful planning and execution. Whether it's relocating heavy equipment at a construction site, transporting industrial machines across the country, or moving agricultural machinery from one field to another, several key factors must be considered to ensure a safe and efficient operation.

First and foremost, proper planning is essential. Before any machinery is moved, it is crucial to assess the equipment's specifications, including its weight, dimensions, and any other unique characteristics that may impact the moving process. Understanding the machinery's size and weight will help determine the type of transportation method required, whether it be a flatbed truck, specialized trailer, or even a helicopter for particularly large and sensitive equipment.

Moreover, it is necessary to evaluate the route for transportation. This involves identifying potential obstacles, such as low bridges, narrow roads, or areas with heavy traffic that could hinder the movement of large machinery. Pre-planning the route can help avoid delays and ensure that the machinery reaches its destination safely and on time.

Safety is another critical consideration when moving large machinery. It’s important to secure the machinery properly during transit to prevent any shifting or damage. Using appropriate rigging equipment, such as chains, straps, or spreader bars, can provide additional security and stability. Furthermore, adhering to local regulations regarding oversized loads is vital. This may involve obtaining permits, utilizing escort vehicles, or adhering to specific travel times to minimize disruption to regular traffic.

moving large machinery

In addition to physical safety measures, having an experienced team in place is crucial for the success of the operation. Trained personnel should be involved in both the disassembly (if necessary) and the reassembly of the machinery. Their expertise can help prevent accidents and ensure that the equipment is reinstalled correctly and operates efficiently after the move.

Lastly, it is beneficial to leverage technology in moving large machinery. Modern advancements, such as GPS tracking and telematics, can provide real-time updates on the location and condition of the equipment during transit. This allows for better communication and timely troubleshooting if unexpected issues arise.

In conclusion, moving large machinery is a multifaceted process that demands meticulous planning, safety precautions, and skilled personnel. By addressing these elements, companies can facilitate efficient relocations that minimize downtime and enhance productivity.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

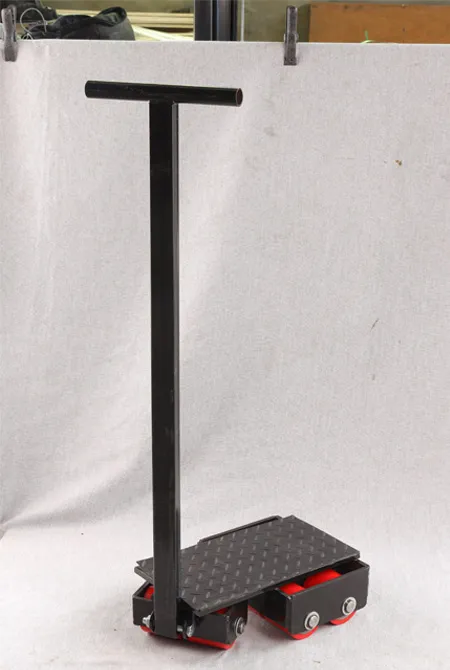

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025