nylon machine skates

Understanding Nylon Machine Skates A Comprehensive Guide

Nylon machine skates have emerged as vital tools in various industries, particularly in manufacturing and logistics. These devices are designed to facilitate the movement of heavy machinery and equipment with minimal effort, reducing the risk of injury and improving efficiency. In this article, we will delve into the features, benefits, applications, and maintenance of nylon machine skates.

What are Nylon Machine Skates?

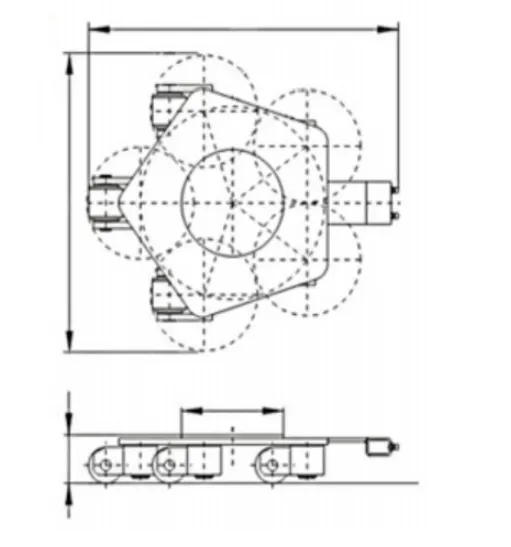

Nylon machine skates, also known as dollies or rigging skates, are low-profile platforms fitted with wheels, primarily made from durable nylon material. Their design allows them to support heavy loads while providing easy maneuverability across different surfaces. The wheels are usually equipped with ball bearings, ensuring smooth rolling even under substantial weight.

Features of Nylon Machine Skates

1. Material Composition Nylon is chosen for its lightweight and robust properties. It is resistant to wear and tear, can withstand high loads, and is less likely to damage floors compared to metal skates.

2. Load Capacity Nylon machine skates come in various sizes and are rated for different load capacities, ranging from a few hundred pounds to several tons. This versatility allows businesses to select skates that fit their specific needs.

3. Wheel Design The wheels on nylon skates typically incorporate a hard nylon or composite material designed to distribute weight evenly. This design minimizes the risk of floor damage and improves mobility on both smooth and rough surfaces.

4. Maneuverability Many models come with swivel casters, allowing for 360-degree movement. This feature is particularly beneficial in tight spaces where precise maneuvering is required.

5. Accessories Some manufacturers offer optional accessories such as straps, pads, or additional stabilization features to enhance the functionality of nylon machine skates.

Benefits of Using Nylon Machine Skates

1. Enhanced Safety Using machine skates to transport heavy equipment significantly reduces the risk of workplace injuries. By minimizing physical strain and risk, workers can focus on their tasks more efficiently.

2. Increased Efficiency Nylon skates allow for quicker and more streamlined procedures in moving heavy machinery. This efficiency can lead to reduced downtime in production environments.

3. Floor Protection Unlike metal skates, which can scratch or damage surfaces, nylon skates are designed to be floor-friendly. This characteristic makes them suitable for various flooring types, including tile, concrete, and wood.

nylon machine skates

4. Cost-Effectiveness Investing in high-quality nylon machine skates can lead to long-term savings. By reducing equipment damage and employee injuries, businesses can significantly lower operational costs.

Applications of Nylon Machine Skates

Nylon machine skates are used across various sectors, including

- Manufacturing In manufacturing facilities, skates help move machinery and heavy loads between stations, ensuring a seamless production process.

- Warehousing For warehouses, nylon skates aid in the transportation of products, enabling quicker stocking and retrieval.

- Construction In construction sites, skates make it easier to relocate heavy equipment, tools, and materials, thus enhancing workflow.

- Automotive The automotive industry uses skates for maneuvering heavy car parts and machinery during assembly and repair tasks.

Maintenance of Nylon Machine Skates

To ensure the longevity and effectiveness of nylon machine skates, regular maintenance is essential. Here are some tips

1. Cleaning Periodically clean the skates to remove debris and dirt that may hinder their movement.

2. Inspection Regularly inspect the wheels and components for wear and tear. Replace any damaged parts immediately to maintain safety.

3. Storage Store skates in a dry place away from direct sunlight and extreme temperatures to prevent material degradation.

Conclusion

In conclusion, nylon machine skates are indispensable tools for various industries, offering numerous benefits in terms of safety, efficiency, and cost-effectiveness. Understanding their features and proper maintenance can lead to significant improvements in operational workflow while ensuring employee safety. Investing in high-quality nylon machine skates can prove to be a wise decision for businesses looking to enhance their productivity and protect their workforce.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025