Optimizing Efficiency and Safety in Double Girder Overhead Crane Design and Operation Techniques

Understanding Double Girder Overhead Cranes Features and Applications

Double girder overhead cranes are essential pieces of equipment widely used in various industries for hoisting and moving heavy loads. These cranes are characterized by their robust structural framework, consisting of two parallel beams (girders) that span the distance between two upright supports or gantry legs. The design of double girder overhead cranes is engineered to provide enhanced stability, greater lifting capacities, and the ability to cover larger work areas compared to their single girder counterparts.

Design and Features

One of the primary advantages of double girder overhead cranes is their sturdy construction. The two girders distribute the load evenly, allowing the crane to lift heavier objects with a higher degree of stability. This is particularly beneficial in manufacturing settings, warehouses, and shipyards, where heavy equipment or materials are frequently moved.

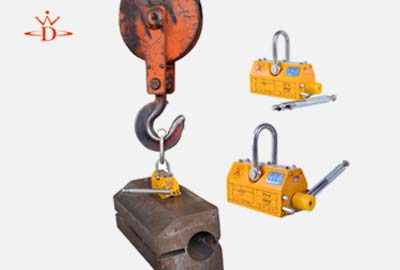

In terms of functionality, double girder cranes are equipped with electric hoists or manually operated winches, enabling precise control over the load being lifted. The hoist can move along the full length of the girders, providing a wide operational range that is ideal for maneuvering large items. Additionally, these cranes can be fitted with various accessories, including magnets, clamps, or tongs, to accommodate different types of loads.

Advantages Over Single Girder Cranes

While single girder cranes are suitable for lighter loads and smaller operational spans, double girder overhead cranes have several advantages that make them a preferred choice in heavy-duty applications.

Firstly, the lifting capacity of double girder cranes is generally higher, often exceeding capacities of 50 tons, depending on the design specifications. This feature is crucial in industries where heavy machinery or large components must be moved frequently.

double girder overhead crane

Secondly, the double girder design allows for a higher hook lift. This means that the hook can be positioned closer to the top of the crane, providing more space beneath the crane for operations. This allows for greater flexibility when maneuvering taller objects and enhances safety by minimizing the risk of collisions.

Lastly, double girder cranes tend to have a longer service life due to their robust design. The materials used are often more durable, and the structure can withstand heavier loads and repeated use without significant wear and tear.

Applications

Double girder overhead cranes are utilized in a variety of applications across several industries. In manufacturing, these cranes are essential for assembly lines, transporting components, and loading finished products. In shipyards, cranes are used for lifting heavy ship parts and equipment during assembly and repairs. Similarly, in construction, they are crucial for moving large structural elements into place.

Moreover, double girder overhead cranes are often found in logistics and warehousing, where they facilitate the organization and movement of goods within large facilities. Their ability to navigate expansive work areas enhances operational efficiency, making them a vital component of many industrial processes.

Conclusion

In conclusion, double girder overhead cranes play a pivotal role in various industrial sectors due to their robust design, high lifting capacity, and versatile applications. As companies continue to seek ways to increase efficiency and productivity, the significance of these cranes in facilitating heavy lifting operations cannot be overstated. Their durability, combined with technological advancements in crane design and automation, ensures that double girder overhead cranes will remain an essential tool in modern industry for years to come. Whether in manufacturing, shipping, or construction, these cranes are indispensable for safely and effectively moving heavy loads.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025