overhead gantry

Understanding Overhead Gantries A Comprehensive Overview

Overhead gantries are a crucial component in various industrial and construction environments, playing an essential role in material handling, logistics, and safety. As integral structural elements, they facilitate the movement of heavy objects, enhance work efficiency, and provide a safer environment for workers. This article aims to elucidate the significance of overhead gantries, their design, applications, and advancements in technology, which enhance their functionality and utility.

What is an Overhead Gantry?

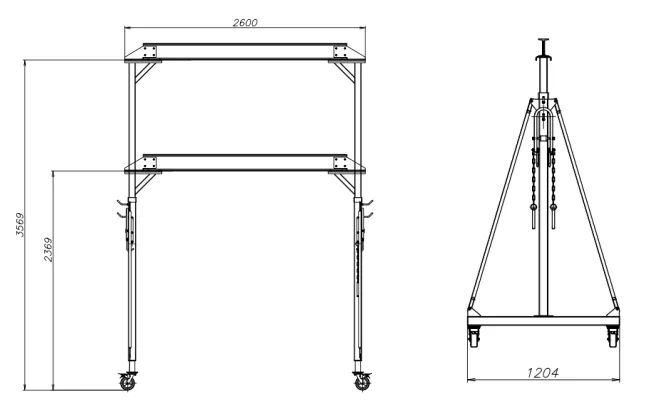

An overhead gantry is a type of gantry crane that consists of a bridge supported by two or more legs, allowing it to move along vertical tracks. These structures are designed to lift and transport materials across a defined area, often utilized in warehouses, manufacturing plants, shipping yards, and construction sites. The primary components of an overhead gantry include the gantry frame, hoist mechanism (which may be electric or manual), and the runway beams that guide movement.

Importance and Applications

Overhead gantries are indispensable in environments where lifting and transporting heavy loads are required. Their applications include

1. Manufacturing and Assembly Plants In high-volume manufacturing facilities, overhead gantries are often employed to streamline assembly lines. They can easily lift components such as metal sheets, machinery parts, and other materials, reducing the risk of manual handling injuries.

2. Warehousing and Logistics In warehousing, these gantries facilitate the efficient moving of goods from one location to another. They save time by allowing for quick access to inventory stored at various heights, ultimately enhancing operational efficiency.

3. Construction Sites Overhead gantries are increasingly used in construction due to their ability to maneuver heavy building materials and equipment. This capability is particularly vital when working on multi-story structures, as it ensures the safe and swift transport of items to different levels.

4. Shipyards and Docks At shipyards, overhead gantries aid in loading and unloading shipping containers, large machinery, and other cargo. Their adaptability and strength make them suitable for various shipbuilding processes as well.

Design Considerations

overhead gantry

The design of an overhead gantry is critical in determining its capacity, stability, and efficiency. Key design aspects include

- Load Capacity Depending on the application, the gantry's design accommodates varying weight capacities ranging from a few hundred pounds to several tons.

- Height and Span The height and span must be optimized to ensure adequate clearance and reach over the intended work area. The choice of dimensions affects maneuverability and operational efficiency.

- Material Selection Materials used in constructing gantries, such as steel or aluminum, must exhibit sufficient strength while maintaining a manageable weight for ease of operation.

- Safety Features Incorporating safety mechanisms like limit switches, emergency stops, and anti-collision systems is crucial for protecting workers and ensuring safe operations.

Advancements in Technology

Recent advancements in technology have significantly enhanced the functionality and efficiency of overhead gantries. Automation and robotics are increasingly integrated into gantry systems, allowing for precise control and reduced labor costs. Programmable logic controllers (PLCs) and sophisticated sensors enhance operational accuracy while minimizing human error.

Moreover, advancements in materials science enable the development of lighter yet stronger gantries, improving load capacities without compromising stability. Smart gantry systems equipped with IoT capabilities also allow for real-time data monitoring, predictive maintenance, and enhanced operational insights.

Conclusion

In conclusion, overhead gantries serve as a backbone in various industries by ensuring efficient and safe material handling. Their applications span multiple sectors, highlighting their versatility and importance in modern operations. As industrial needs evolve, ongoing advancements will undoubtedly enhance the functionality and efficiency of these essential lifting systems. Understanding the significance of overhead gantries not only promotes safer workplaces but also drives productivity and innovation across diverse fields. Embracing these technologies will pave the way for smarter, more reliable solutions in material handling and beyond.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025