Design and Implementation of an Overhead Gantry System for Industrial Applications

Understanding Overhead Gantries Applications, Benefits, and Safety Considerations

Overhead gantries are essential structures used in various industrial and construction applications. Their design typically includes a framework that spans across an area to support moving equipment, such as cranes, conveyor systems, or even signage. These structures enhance efficiency and safety in environments where heavy lifting or transportation of materials is necessary. In this article, we’ll explore the applications, benefits, and safety considerations associated with overhead gantries.

Applications of Overhead Gantries

Overhead gantries are versatile and find applications in numerous fields. One prevalent use is in manufacturing facilities where they facilitate the movement of heavy loads across the production floor. By utilizing overhead gantries, companies can minimize the need for floor space and ensure a smoother workflow. For instance, automotive factories use these systems to transport parts from assembly lines to staging areas, thereby improving productivity.

In the construction industry, overhead gantries are invaluable for lifting and moving heavy materials. They can be set up on-site to hoist items like steel beams, concrete panels, and other significant components. This capability not only speeds up the construction process but also enhances safety by reducing the risk of transporting heavy materials via forklifts in crowded environments.

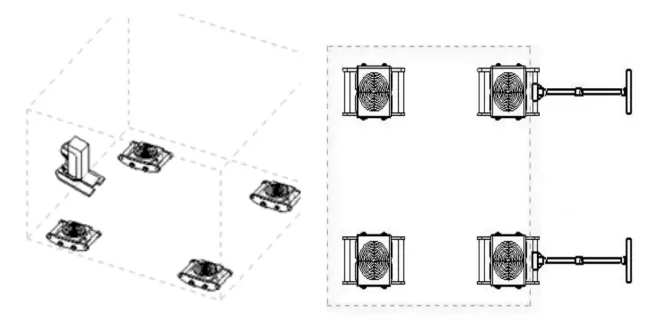

Another intriguing application can be found in municipal infrastructure, particularly with traffic management. Overhead gantries are often employed to support traffic signals and electronic message boards. They allow for better visibility of these signs, helping regulate traffic flow and improve safety for drivers and pedestrians alike. Additionally, these gantries often serve as platforms for cameras and sensors, enabling real-time monitoring of traffic conditions.

Benefits of Overhead Gantries

The adoption of overhead gantries presents numerous benefits for businesses and industries. One primary advantage is space optimization. By utilizing vertical space, businesses can streamline their operations without expanding their physical footprint. This is particularly beneficial in urban settings where real estate is limited and costs are high.

over head gantry

In terms of safety, overhead gantries contribute to a safer work environment. By transferring the load to an overhead system, workers are protected from the risks associated with manual lifting and transportation of heavy items. Furthermore, they provide a more organized workspace, reducing clutter on the floor and minimizing the chance of accidents.

Another benefit is the improved efficiency afforded by these systems. Overhead gantries can significantly speed up processes that involve moving materials from one place to another. With cranes or hoists attached, the timeframe for loading and unloading materials is reduced, allowing businesses to meet tight production schedules and adapt to changing workloads more effectively.

Safety Considerations

Despite the many advantages of overhead gantries, there are critical safety considerations that must be addressed. Regular inspections and maintenance are crucial to ensure the structural integrity of the gantry and its components. This includes checking for wear and tear on the hoisting mechanisms, inspecting support beams, and ensuring that all safety features are operational.

Training for personnel operating machinery attached to the gantry is equally important. Operators must be familiar with the equipment and its limitations to prevent accidents. Moreover, establishing clear communication protocols among team members can further enhance safety during operations.

Lastly, employers must comply with regulatory standards and guidelines relating to overhead gantries. This includes adhering to weight limits and ensuring that all safety guardrails and barriers are in place to protect workers and bystanders. Proper signage should also be used to warn personnel of the potential dangers associated with working under or near an overhead gantry.

Conclusion

In summary, overhead gantries play a pivotal role in various industries, offering advantages such as space optimization, increased safety, and improved efficiency in handling heavy loads. However, it is essential to prioritize safety by conducting regular inspections, providing sufficient training for operators, and complying with regulatory standards. As industries continue to evolve, the significance of overhead gantries will undoubtedly remain, driving innovation and productivity while ensuring a safer working environment.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025