Design and Functionality of Overhead Gantry Systems in Industrial Applications

The Overhead Gantry An Essential Tool in Modern Industry

The overhead gantry, often referred to as a gantry crane, is a crucial piece of equipment in various industrial settings. These cranes are designed to lift and move heavy loads with ease and precision, making them indispensable in manufacturing, shipping, and construction sectors. As industries continue to evolve and expand, the demand for efficient and effective material handling solutions, like the overhead gantry, has surged.

Design and Structure

An overhead gantry consists of a horizontal beam supported by two or more legs that run along rails. This design allows the crane to move along a defined path, providing flexibility in handling materials. The movement can be both lateral and vertical, enabling operators to position loads exactly where they need them. Depending on the application, overhead gantries can be constructed from various materials, including steel and aluminum, which offer strength and durability.

One of the critical design features of an overhead gantry is the hoist mechanism, typically equipped with a trolley that can travel along the main beam. This hoist is capable of lifting heavy items, ranging from several tons to much heavier loads, making it suitable for diverse applications. Furthermore, modern overhead gantries are often equipped with advanced control systems, allowing for precise movements and enhanced safety features.

Applications Across Industries

The versatility of overhead gantries allows them to be utilized in a wide range of industries. In manufacturing, they are commonly used for assembling large components, moving parts from one station to another, and managing inventory. In shipping yards, these cranes facilitate the loading and unloading of containers, significantly speeding up logistics operations. Construction sites also rely on overhead gantries for lifting materials, steel beams, and heavy equipment, ensuring that projects can proceed smoothly and on schedule.

Moreover, overhead gantries have found applications in industries such as metalworking, automotive, and warehouses. Their ability to streamline workflows and improve efficiency makes them an attractive option for businesses seeking to optimize their operations. The automation capabilities of modern gantries further enhance their utility, enabling seamless integration into advanced manufacturing and logistics systems.

overhead gantry

Safety Considerations

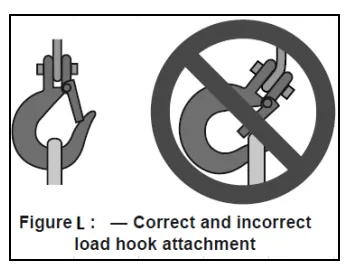

While overhead gantries provide immense benefits, their operation comes with potential hazards. It is crucial for operators to receive proper training and adhere to safety protocols to prevent accidents. Regular maintenance and inspections are vital to ensure that the crane's components are in good working order and functioning correctly.

Implementing safety features such as limit switches, anti-collision systems, and emergency stop buttons can significantly reduce the risk of accidents. Additionally, the use of appropriate personal protective equipment (PPE) is essential for those working in proximity to the cranes. Creating a safety-conscious culture within the workplace can further mitigate risks associated with overhead gantry operations.

Future Trends

As technology continues to advance, the future of overhead gantries looks promising. Innovations in automation and artificial intelligence are set to enhance their capabilities, improving efficiency and safety. Automated overhead gantries can operate with minimal human intervention, allowing for increased throughput and reduced labor costs.

Furthermore, the integration of IoT (Internet of Things) technology can enable real-time monitoring of the gantry’s performance, helping companies identify potential issues before they become critical. This proactive approach to maintenance and operation can lead to increased productivity and reduced downtime.

In conclusion, the overhead gantry is a fundamental piece of equipment that plays a pivotal role in modern industrial operations. Its unique design, versatility in applications, and potential for incorporation of innovative technologies position it as an essential tool for companies aiming to enhance productivity and efficiency. As industries continue to grow and evolve, overhead gantries will undoubtedly remain a cornerstone of effective material handling solutions, adapting to meet the needs of the future.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025