overhead gantry system

Overhead Gantry Systems Revolutionizing Material Handling

In today's fast-paced industrial environment, efficient material handling is crucial for enhancing productivity and streamlining operations. One technological advancement that has significantly contributed to improving logistics and manufacturing capabilities is the overhead gantry system. This article delves into the functionalities, advantages, and applications of overhead gantry systems, showcasing their importance across various industries.

What is an Overhead Gantry System?

An overhead gantry system consists of a framework or structure that supports a movable hoist or trolley, allowing for the lifting and transportation of heavy materials and equipment across a designated area. Typically mounted on beams or rails, these systems can operate without the constraints of the floor space, which is particularly beneficial in facilities with limited ground area. The design allows the gantry to move horizontally and vertically, providing optimal accessibility to various workstations and storage areas.

Key Components

Overhead gantry systems are composed of several critical components, including

1. Gantry Structure This includes the horizontal beam (or beams) supported by vertical legs. The height and span of the gantry can be customized depending on the specific application.

2. Hoist At the heart of the gantry system, the hoist is responsible for lifting and lowering loads. Various types of hoists can be used, including electric, pneumatic, or manual options, depending on the weight of the materials being moved.

3. Trolley The trolley travels along the beam, allowing the hoist to move horizontally. This versatility enables workers to position loads precisely where needed.

4. Control System Advanced overhead gantry systems come equipped with electronic controls that enhance operation safety and efficiency. This may include remote controls, limit switches, and safety sensors.

Advantages of Overhead Gantry Systems

Overhead gantry systems offer numerous advantages that make them a preferred choice in various industries

1. Space Efficiency By utilizing the overhead space, these systems free up valuable floor space for other activities, such as assembly lines or storage. This is particularly important in smaller facilities.

overhead gantry system

2. Versatility They can be tailored to meet unique lifting and transportation needs. Whether moving heavy machinery or handling large components, overhead gantry systems accommodate a wide range of applications.

3. Safety With the capability to handle heavy loads safely and reliably, these systems reduce the risk of accidents associated with manual lifting. Additionally, many designs integrate safety features that prevent overloads and enhance operator protection.

4. Increased Productivity By automating the lifting and moving processes, overhead gantry systems significantly speed up operations, leading to reduced labor costs and improved throughput.

5. Durability Built to withstand harsh industrial environments, these systems are typically constructed from sturdy materials like steel, providing resilience and longevity in demanding applications.

Applications Across Industries

Overhead gantry systems are employed across a wide array of industries, including

1. Manufacturing In manufacturing facilities, these systems are used for assembling products, moving heavy equipment, and loading/unloading materials from trucks or storage.

2. Construction In construction sites, overhead gantries facilitate the lifting and repositioning of heavy construction materials, such as steel beams and concrete panels.

3. Warehouse and Distribution Warehouses utilize overhead gantry systems to streamline the movement of goods, enhancing inventory management and shipping processes.

4. Automotive In automotive repair and assembly lines, these systems are essential for lifting engines, chassis, and other heavy components, allowing for efficient assembly and servicing of vehicles.

5. Shipbuilding Overhead gantries are integral to shipyards, where they manage heavy components and equipment required for constructing and repairing ships.

Conclusion

In conclusion, overhead gantry systems represent a vital innovation in material handling technology. Their ability to improve efficiency, enhance safety, and maximize space utilization makes them an indispensable asset across various industrial sectors. As industries continue to evolve, the demand for advanced solutions like overhead gantry systems will undoubtedly grow, paving the way for future advancements in automation and operational excellence.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

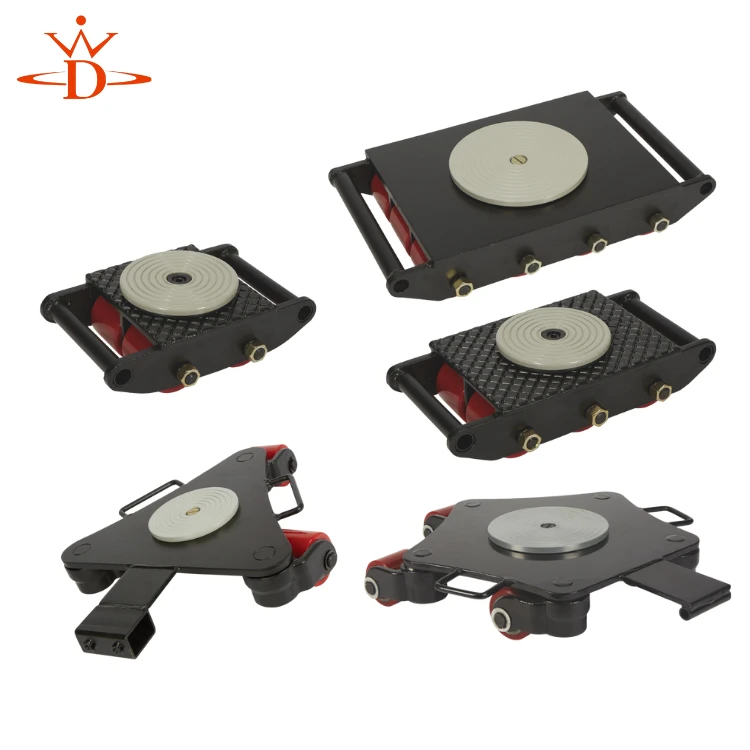

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025