overhead gantry system

Understanding Overhead Gantry Systems A Comprehensive Overview

Overhead gantry systems have become an integral part of modern industrial operations. These systems are designed to move heavy loads efficiently across a defined workspace, making them indispensable in environments such as warehouses, factories, and construction sites. With their ability to enhance productivity and reduce manual labor, overhead gantry systems represent a crucial advancement in material handling technology.

What is an Overhead Gantry System?

An overhead gantry system consists of a structure—typically supported by columns—that spans a workspace and houses a hoist mechanism for lifting and moving loads. The gantry's design allows it to traverse the length of the area, ensuring that heavy materials can be transported with minimal physical effort. The systems are often seen in settings where space optimization is critical, as they utilize vertical space to facilitate horizontal movement.

Key Components

1. Gantry Frame The primary framework is composed of vertical legs connected by a horizontal beam, which provides stability and support. The gantry can be fixed or portable, depending on the specific operational requirements.

2. Hoist Mechanism At the heart of the gantry system is the hoisting mechanism, which can be electric, manual, or pneumatic. This component is responsible for lifting and lowering various loads and often incorporates features such as speed control and safety brakes.

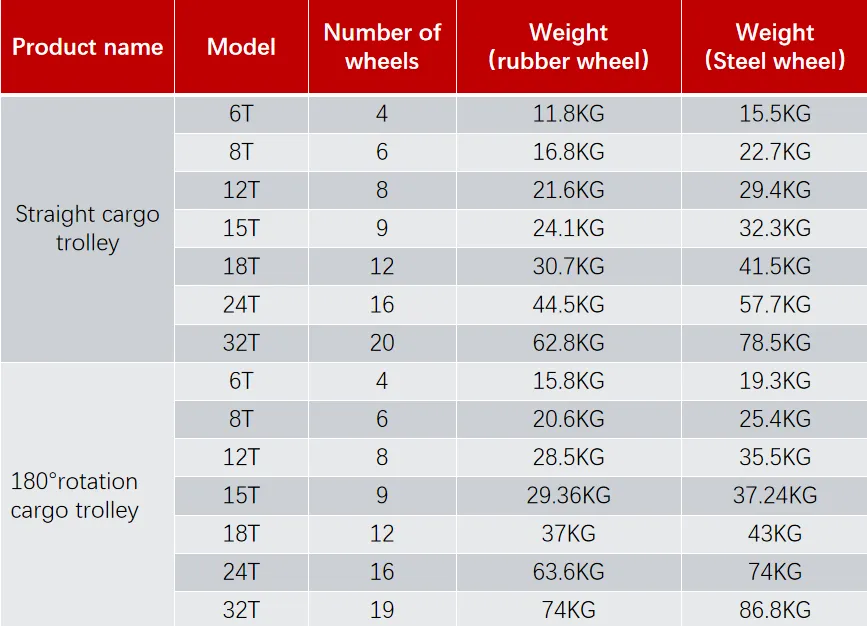

3. Wheels and Tracks The gantry usually moves on wheels that roll along tracks, allowing for smooth and efficient movement across the space. Some systems incorporate caster wheels for easy mobility, while others are designed for heavy-duty applications with fixed tracks.

4. Control Systems Modern overhead gantry systems often come equipped with advanced control systems. These may include remote controls, programmable interfaces, and safety features that enhance operational efficiency while minimizing the risk of accidents.

Benefits of Overhead Gantry Systems

The implementation of an overhead gantry system offers several advantages

overhead gantry system

1. Increased Efficiency By enabling the movement of heavy items without the need for manual labor, businesses can significantly enhance productivity. Workers can focus on other essential tasks, effectively optimizing overall workflow.

2. Space Optimization Overhead gantry systems are particularly beneficial in environments where floor space is limited. Their design utilizes overhead space, allowing for the arrangement of materials below and eliminating the need for large floor-based equipment.

3. Safety Enhancements Safety is a paramount concern in industrial operations. Overhead gantry systems minimize the risk of injuries associated with manual lifting, as heavy items are moved mechanically. Additionally, many systems incorporate safety features that prevent accidents during operation.

4. Flexibility Many overhead gantry systems can be customized to suit specific needs. This flexibility allows businesses to adapt their equipment to various tasks, from simple material handling to complex assembly operations.

Applications

Overhead gantry systems are prevalent across numerous industries, including

- Manufacturing Used for transporting components between different stages of production, improving assembly line efficiency.

- Construction Assisting in the hoisting of heavy materials such as steel beams and concrete blocks, facilitating quicker construction processes.

- Shipping and Logistics In warehouses, gantry systems streamline the loading and unloading of products, speeding up distribution efforts.

Conclusion

In summary, overhead gantry systems represent a vital component of modern industrial operations. Their ability to move heavy loads with efficiency and safety makes them indispensable in a wide range of applications. As industries continue to evolve, the integration of advanced technology within these systems will further enhance their efficacy, ultimately leading to increased productivity and better safety practices. Companies looking to improve their material handling processes would benefit greatly from considering the implementation of an overhead gantry system as part of their operational strategy. With their combination of versatility, efficiency, and safety, these systems will undoubtedly continue to play a significant role in shaping the future of industrial work environments.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025