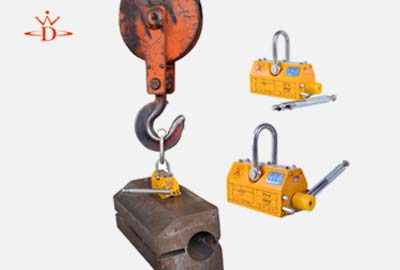

permanent lifting magnet

Understanding Permanent Lifting Magnets A Comprehensive Overview

In the world of heavy industry and manufacturing, efficiency and safety are paramount. One tool that has vastly improved these aspects of material handling is the permanent lifting magnet. These devices have revolutionized the way industries move and manipulate ferrous materials, making operations more effective and less labor-intensive.

What Are Permanent Lifting Magnets?

Permanent lifting magnets are devices designed to lift and hold ferromagnetic materials using the principles of magnetism. They utilize a permanent magnet to generate a strong magnetic field that can securely lift heavy objects such as steel plates, pipes, and other metallic components. Unlike electromagnets, which require an electrical current to generate a magnetic field, permanent magnets retain their magnetic properties indefinitely, providing several advantages for industrial applications.

How Do They Work?

The basic operation of a permanent lifting magnet involves a magnetic circuit that includes the magnet, the workpiece, and the distance between them. When the lifting magnet is positioned over a ferrous material, the magnetic field penetrates the material and induces magnetization. The magnetic force is then sufficient to lift the object, enabling the handling of heavy loads with minimal effort.

These magnets are often equipped with a lever or switch mechanism, allowing operators to engage and disengage the magnet easily. This simplicity increases the efficiency of material handling processes while reducing the risk of injury from manual lifting.

Advantages of Permanent Lifting Magnets

1. Energy Efficiency Since permanent magnets do not require electricity to maintain their magnetic field, they are energy-efficient. This feature is particularly beneficial in environments where power supply may be limited or where operations are intended to be cost-effective.

permanent lifting magnet

2. Low Maintenance Permanent lifting magnets have fewer moving parts compared to electric lifting devices, which means they generally require less maintenance. This durability translates into lower operational costs and minimized downtime.

3. Enhanced Safety The use of permanent lifting magnets reduces the need for manual handling of heavy materials, thereby decreasing the risk of injury among workers. Moreover, these magnets are designed to hold loads securely, minimizing the likelihood of slippage and accidents during transportation.

4. Versatility Permanent lifting magnets can be used in a variety of applications, from manufacturing and construction to warehousing and shipping. They can lift items of various shapes and sizes, making them an ideal solution for diverse industrial settings.

5. Portability Many models of permanent lifting magnets are lightweight and portable, allowing for easy movement and relocation. This portability is particularly advantageous in dynamic work environments where the layout may frequently change.

Applications in Industry

Permanent lifting magnets find applications across multiple industries. In metal fabrication shops, they are commonly used for lifting plates and beams, while in construction, they assist in positioning large steel frameworks. Additionally, in warehouses and distribution centers, these magnets are employed to move heavy items efficiently, improving workflow and productivity.

Conclusion

Permanent lifting magnets are a testament to modern engineering, offering sustainable solutions for heavy lifting challenges. Their efficiency, safety features, and versatility make them invaluable tools in various industrial sectors. As industries continue to evolve, the applications and technology surrounding permanent lifting magnets will likely expand, further enhancing productivity and safety in material handling processes. For businesses looking to streamline their operations and improve worker safety, investing in permanent lifting magnets is a step in the right direction.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025