permanent lifting magnets with on off control

Permanent Lifting Magnets with On/Off Control Revolutionizing Material Handling

In today’s industrial landscape, efficiency and safety are paramount. As manufacturers continuously seek ways to optimize operations, permanent lifting magnets with on/off control have emerged as a game-changing solution for material handling. These innovative tools not only enhance productivity but also reduce workplace hazards associated with traditional lifting methods.

Understanding Permanent Lifting Magnets

Permanent lifting magnets utilize a magnetic field generated by permanent magnets to securely lift and handle ferrous materials. Unlike electromagnets, which require a constant electrical supply, permanent magnets can hold their magnetic force without energy consumption, making them an energy-efficient option. This feature is particularly beneficial in environments where energy costs are a concern.

The On/Off Control Mechanism

The introduction of on/off control in permanent lifting magnets brings a new level of convenience and safety to material handling. This mechanism allows operators to easily engage or disengage the magnetic force at will, providing enhanced control over the lifting process. By simply activating a switch, the operator can turn the magnet on to lift loads and switch it off to release them. This immediacy promotes smoother workflows and reduces the chances of accidents caused by manual handling.

Applications in Various Industries

The versatility of permanent lifting magnets with on/off control makes them suitable for a wide range of industries. In manufacturing settings, they are commonly used to lift steel plates, pipes, and other heavy components. In construction, these magnets facilitate the movement of rebar and other ferrous materials, streamlining the building process.

Moreover, the recycling industry benefits significantly from these lifting devices, as they are perfect for sorting and transporting scrap metal

. Their ability to handle various sizes and weights makes them ideal for dynamic environments where efficiency is crucial.permanent lifting magnets with on off control

Safety Considerations

Safety is always a primary concern when handling heavy materials. Permanent lifting magnets with on/off control significantly enhance safety protocols in the workplace. The magnets minimize the risk of injuries that can occur from manual lifting, falling objects, or equipment malfunctions.

In addition, the clear visibility of the magnetic force status—whether the magnet is engaged or not—allows operators to remain vigilant during lifting operations. Training staff on proper usage and safety procedures further ensures that the benefits of these magnets are fully realized without compromising workplace safety.

Cost-Effectiveness and Return on Investment

Investing in permanent lifting magnets with on/off control can lead to substantial long-term savings. By reducing the need for manual labor and minimizing the risk of injury, production costs are lowered significantly. Furthermore, the durability and longevity of permanent magnets mean that companies can expect a reliable return on investment.

Companies often report increased efficiency and faster production cycles after integrating these devices into their operations. As a result, businesses can complete projects more quickly and with fewer resources, which ultimately boosts profitability.

Conclusion

In conclusion, permanent lifting magnets with on/off control are transforming the way industries approach material handling. Their energy efficiency, safety features, and cost-effectiveness make them an invaluable asset in various applications. As industries continue to innovate and strive for greater efficiency, these lifting devices will undoubtedly play a crucial role in shaping the future of material handling. Embracing this technology could mean the difference between a standard operation and one that leads the industry in safety, efficiency, and productivity.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

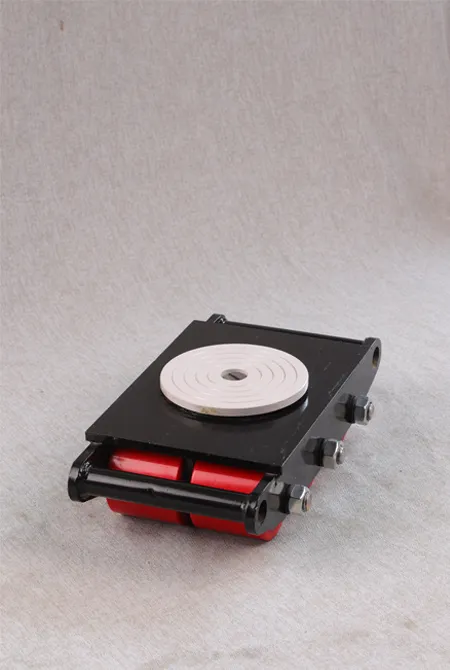

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025