permanent magnetic lifter

Understanding Permanent Magnetic Lifters An Essential Tool for Industries

In the realm of material handling and industrial operations, efficiency and safety are paramount. One innovative solution that has gained popularity in recent years is the permanent magnetic lifter. This tool harnesses the power of permanent magnets to lift and transport heavy loads without the need for electricity, making it an environmentally friendly and cost-effective option for various applications.

How Permanent Magnetic Lifters Work

Permanent magnetic lifters function based on the principles of magnetism. They utilize high-density permanent magnets to create a strong magnetic field. When activated, the magnetic force allows the lifter to adhere to ferromagnetic materials, such as steel plates and blocks, enabling them to be lifted safely. These lifters are designed to be simple to operate; users can activate and deactivate the magnetic force through a manual lever or switch, which is essential for lifting and releasing loads.

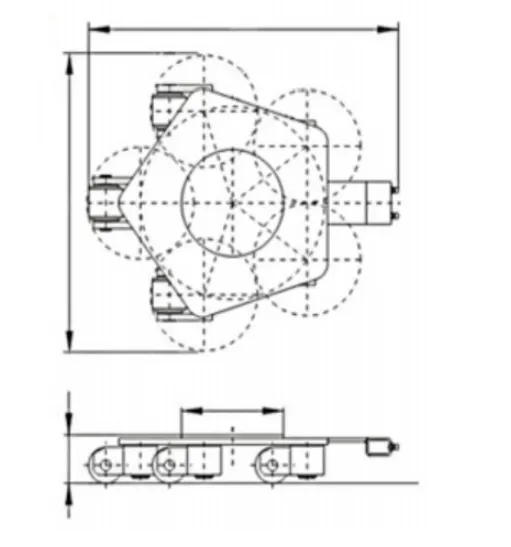

The design of a permanent magnetic lifter typically includes a sturdy base and a gripping mechanism, often in the form of multiple magnets arranged strategically to distribute the load evenly. This design minimizes the risk of slippage or accidental release, enhancing safety in industrial environments where heavy materials are frequently moved.

Applications in Industry

Permanent magnetic lifters are versatile tools used across various industries, including manufacturing, construction, logistics, and warehousing. One of the key applications is in the steel and metalworking industries, where they are employed to lift and maneuver heavy metal sheets, pipes, and other materials. This capability significantly reduces the need for traditional lifting equipment, such as cranes or forklifts, which can be more cumbersome and require additional personnel to operate safely.

permanent magnetic lifter

In logistics and warehousing operations, these lifters streamline the process of loading and unloading goods. They can be used to lift multiple stacks of items efficiently, enabling workers to manage inventory effectively with minimal downtime. Moreover, by employing magnetic lifters, businesses can reduce the risk of injury associated with manual lifting, thus promoting a safer working environment.

Advantages of Using Permanent Magnetic Lifters

One of the most significant advantages of permanent magnetic lifters is their energy efficiency. Unlike electric or hydraulic lifting systems, these lifters do not require power to maintain the magnetic field, which leads to lower operational costs. Additionally, their portability and lightweight design allow for easy handling, making them suitable for both indoor and outdoor use.

From a safety perspective, magnetic lifters are equipped with features that enhance secure lifting. Many models come with a safety factor that exceeds the lifter's rated capacity, providing an added layer of safety in case of unexpected circumstances. Moreover, their robust construction ensures durability, making them a reliable choice for heavy-duty applications.

Conclusion

As industries continue to evolve and seek more efficient solutions for material handling, permanent magnetic lifters stand out as a practical option. Their ability to simplify lifting processes, along with their cost-effectiveness and safety features, makes them an essential tool in modern industrial operations. Whether in manufacturing, logistics, or construction, the integration of permanent magnetic lifters can lead to enhanced productivity and a safer working environment, paving the way for a more efficient future in material handling.

In summary, the growing adoption of permanent magnetic lifters exemplifies the innovative spirit of industries that prioritize safety, efficiency, and cost-effectiveness, demonstrating a commitment to advancing operational practices while prioritizing the well-being of workers. The future holds exciting possibilities as these tools become increasingly sophisticated and integrated into various industrial workflows.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025