pml magnetic lifter

The Power of PML Magnetic Lifters Revolutionizing Heavy Lifting

In the realm of industrial lifting solutions, PML (Permanent Magnetic Lifter) technology has emerged as a game-changer. These devices utilize the principles of magnetism to simplify the handling of heavy materials, making them an indispensable tool in manufacturing, construction, and logistics industries. This article explores the advantages, applications, and working mechanisms of PML magnetic lifters, illustrating their significance in modern operations.

Advantages of PML Magnetic Lifters

One of the most compelling advantages of PML magnetic lifters is their ability to safely lift heavy loads without the need for mechanical power sources such as electricity or compressed air. This not only reduces operational costs but also minimizes the risk of accidents associated with electrical failures or improper wiring. The absence of moving parts means less maintenance is required, enhancing the lifter’s longevity and reliability.

PML lifters are designed to provide strong holding forces, often capable of lifting loads several times their own weight. The gripping strength is magnified by the magnetic field generated by permanent magnets, ensuring that the load remains secure even when moved across uneven surfaces. This feature is particularly advantageous when handling steel plates, beams, and other ferromagnetic materials.

Another significant benefit is their portability and ease of use. PML magnetic lifters are typically lightweight and equipped with ergonomic handles, allowing operators to maneuver them with relative ease. Quick attachment and detachment from loads facilitate rapid workflows, a crucial aspect in environments where time efficiency is paramount.

Applications Across Industries

PML magnetic lifters find wide-ranging applications across various sectors. In the manufacturing industry, they are commonly used to lift and maneuver heavy metal sheets, components, and assemblies, dramatically improving efficiency in production lines. The automotive sector also relies on these devices for transporting engine blocks, chassis components, and other heavy parts during assembly processes.

pml magnetic lifter

Construction sites frequently utilize PML magnetic lifters to position steel beams and panels, contributing to safer and quicker construction practices. The ability to lift heavy materials without the need for additional equipment reduces the number of operators required on-site, thus optimizing labor resources.

Moreover, the logistics industry benefits from magnetic lifters in warehouses and distribution centers, where goods need to be moved swiftly and securely. The risk of damage to products is minimized when using a PML lifter, as the magnetic grip eliminates the need for slings or chains that can scratch or dent surfaces.

How PML Magnetic Lifters Work

At the core of a PML lifter is a series of permanent magnets, strategically arranged to create a strong magnetic field when activated. Unlike electromagnets, which require a continuous power supply, permanent magnets maintain their magnetic properties indefinitely, allowing for reliable and consistent operation. The lifter typically features a simple on/off switch to engage or disengage the magnetic field, enabling safe and efficient control over the lifting process.

To operate a PML magnetic lifter, the device is placed on the load's surface, and the switch is activated. Once engaged, the permanent magnets create an intense magnetic field that securely adheres to the ferromagnetic material. When it's time to release the load, the operator simply switches off the magnetic field, allowing for an easy and quick disengagement.

Conclusion

PML magnetic lifters are redefining the standards of heavy lifting in various industries. With their cost-effectiveness, ease of use, and exceptional safety features, they stand out as essential tools in modern material handling practices. As industries continue to evolve and the demand for efficient lifting solutions grows, PML technology is poised to play a pivotal role in shaping the future of logistics and manufacturing operations. Investing in PML magnetic lifters not only enhances operational effectiveness but also promotes a safer working environment, ensuring that heavy lifting is no longer a daunting task.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

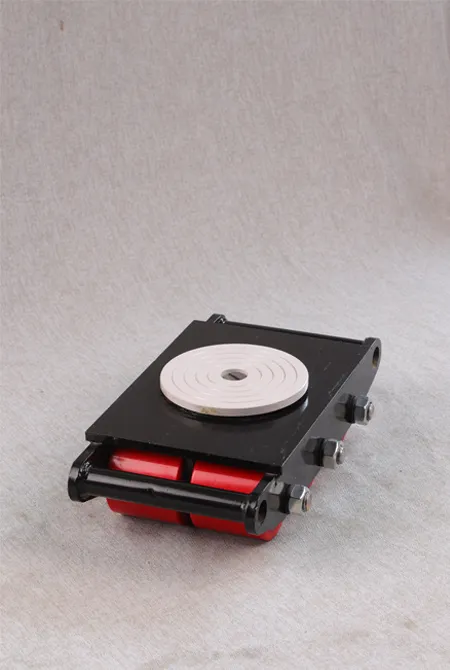

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025