Powerful 1 Ton Lifting Magnet for Heavy Duty Industrial Applications and Reliable Performance

Understanding the 1-Ton Lifting Magnet Features and Applications

Lifting magnets play a critical role in various industries, particularly in material handling and manufacturing. One of the most common types of lifting magnets is the 1-ton lifting magnet, which offers both efficiency and reliability in moving heavy ferromagnetic materials. In this article, we will explore the design, functionality, and applications of a 1-ton lifting magnet.

Design and Functionality

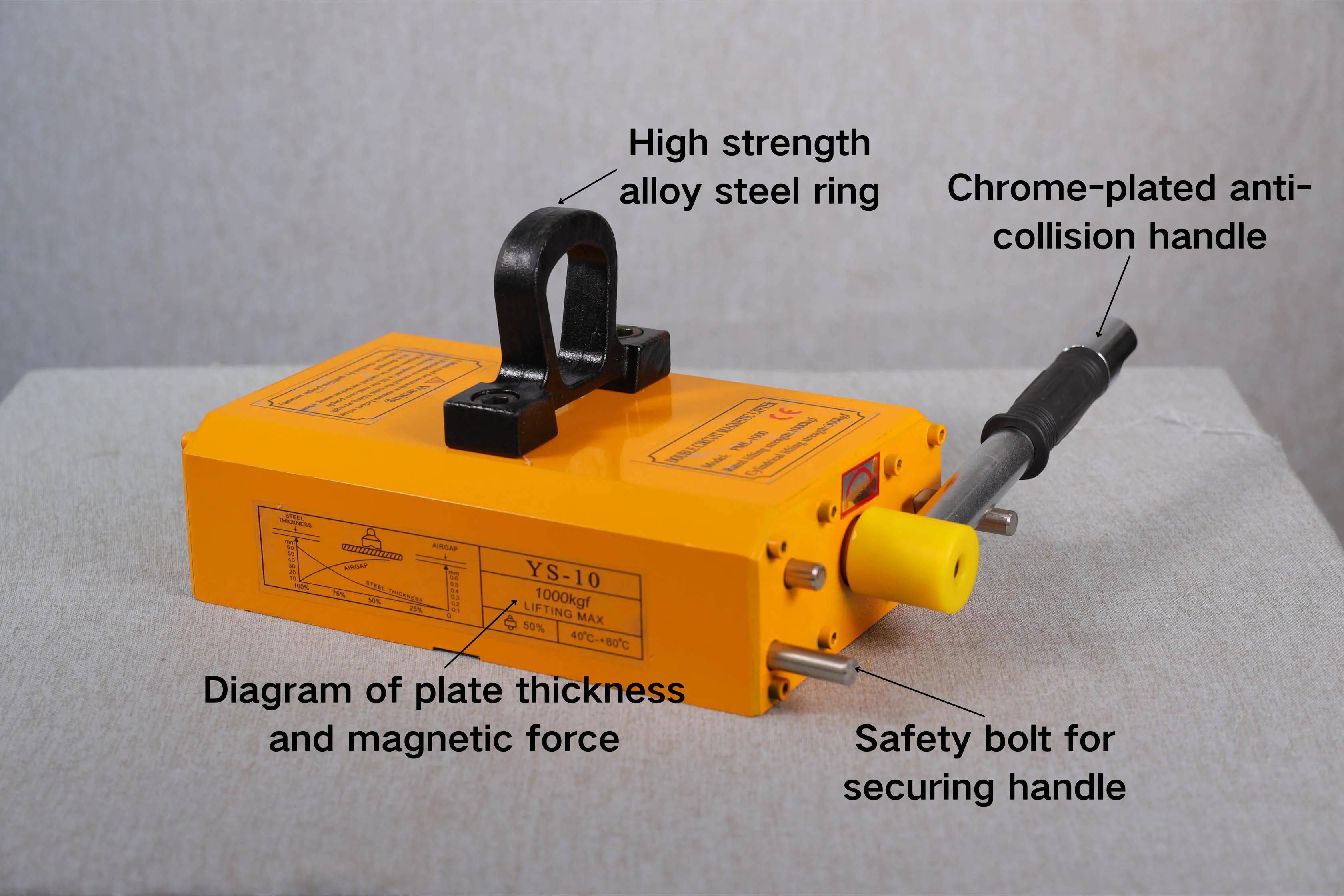

The core component of a lifting magnet is its electromagnetic system, which generates a strong magnetic field when electrical current passes through it. A 1-ton lifting magnet is specifically designed to handle loads up to 1 ton (about 2,200 pounds) safely and effectively. This capacity makes it ideal for various industrial tasks, including lifting steel plates, beams, and other ferrous materials.

Most 1-ton lifting magnets are constructed with high-grade materials that ensure durability and robustness. The housing is typically made from steel, which not only protects the internal components but also aids in the magnet's performance. The magnetic circuit is engineered to maximize magnetic flux, resulting in improved lifting efficiency.

One of the key features of a 1-ton lifting magnet is its easy operation. Many models come equipped with a simple on/off switch, allowing operators to quickly engage or disengage the magnet as needed. Some advanced models include remote controls, thereby enhancing safety and ease of use, particularly in large or hazardous work environments.

Safety Considerations

Safety is paramount when using lifting magnets. A 1-ton lifting magnet should always be used in accordance with manufacturer guidelines to avoid accidents. It is essential to conduct regular inspections to ensure that the magnet is functioning correctly and that the electrical components are in good condition.

lifting magnet 1 ton

Additionally, operators should be trained in proper lifting techniques and safety protocols. This includes understanding the load limits, identifying appropriate lifting points, and ensuring that the path of travel is clear of obstacles. Personal protective equipment (PPE) should also be worn to protect workers in case of accidental slippage or equipment failure.

Applications of 1-Ton Lifting Magnets

The applications of a 1-ton lifting magnet are vast and varied. In manufacturing, these magnets are commonly used to move heavy steel parts during assembly processes. Their ability to simplify the lifting of awkward or heavy components saves both time and labor costs.

Moreover, in construction, a 1-ton lifting magnet can be invaluable for handling rebar, steel beams, and precast concrete elements. The efficiency of lifting magnets helps to streamline operations, leading to safer and faster project completions.

In recycling and scrap yards, lifting magnets are essential for sorting and moving large quantities of scrap metal. The magnetic force allows for quick separation of ferrous materials from non-ferrous materials, significantly improving the efficiency of recycling processes.

Conclusion

In conclusion, a 1-ton lifting magnet is an essential tool in various industries, offering a combination of power, durability, and ease of use. Its design and operational features make it suitable for a wide range of applications, from manufacturing to construction and recycling. Understanding the functionality, safety considerations, and diverse uses of a 1-ton lifting magnet is crucial for maximizing its benefits and ensuring the safety of all personnel involved in material handling tasks. As industries continue to evolve, the reliance on effective lifting solutions like the 1-ton lifting magnet will undoubtedly grow, reaffirming its place in modern operations.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025