Powerful Industrial Lifting Magnets for Efficient and Safe Material Handling Solutions

The Role of Industrial Lifting Magnets in Modern Manufacturing

Industrial lifting magnets have become an indispensable tool in the realm of manufacturing and heavy lifting. These powerful devices utilize magnetic fields to lift ferromagnetic materials such as steel and iron. Their efficiency and effectiveness have made them a popular choice in various industries, from construction and metal fabrication to recycling and transportation. In this article, we will explore the operational principles, benefits, and applications of industrial lifting magnets.

How Do Industrial Lifting Magnets Work?

At the core of industrial lifting magnets is the principle of electromagnetism. These magnets consist of a coil of wire wound around a metal core, typically made of iron. When an electric current passes through the coil, it generates a magnetic field that magnetizes the core, allowing it to lift heavy metal objects. Unlike permanent magnets, industrial lifting magnets can be turned on and off, providing flexibility and control during operations.

There are two main types of industrial lifting magnets permanent magnets and electromagnets. Permanent magnets create a constant magnetic field and are suitable for lighter loads. In contrast, electromagnets can generate a much stronger magnetic field when activated, making them ideal for lifting heavy items. The capacity of these devices can vary significantly, from a few hundred pounds to several tons, depending on the design and power used.

Advantages of Industrial Lifting Magnets

1. Improved Safety Traditional lifting methods, such as hooks and chains, pose several safety risks, including the potential for slippage or accidents. Industrial lifting magnets reduce these risks by providing a secure grip on the material. This stability not only safeguards the workers but also protects the integrity of the load being lifted.

2. Enhanced Efficiency Utilizing lifting magnets streamlines the lifting process. They allow for quick loading and unloading, thus reducing the time required for material handling. This increased efficiency can significantly improve productivity in manufacturing and construction environments.

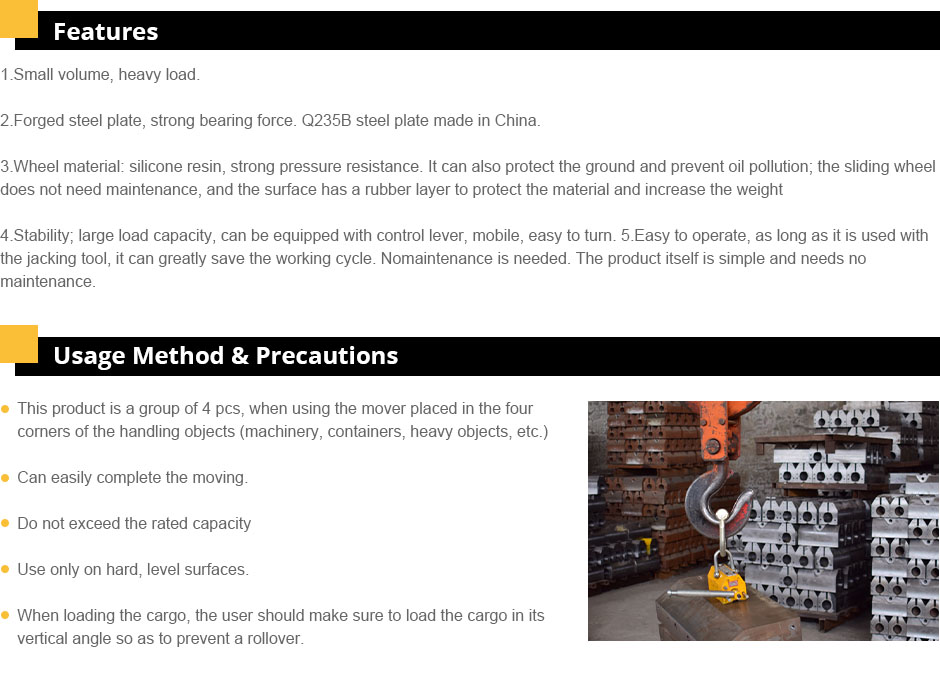

industrial lifting magnets

3. Reduced Labor Costs By minimizing the number of workers needed to handle heavy loads, companies can reduce labor costs. Lifting magnets can often be operated by a single worker, allowing teams to allocate their resources more efficiently.

4. Versatility These lifting magnets are versatile and can be used in various applications, such as moving steel sheets, bars, or scrap metal. Their adaptability makes them valuable in diverse settings, from warehouses to outdoor construction sites.

Applications of Industrial Lifting Magnets

Industrial lifting magnets find applications in multiple sectors. For instance, in the automotive industry, they are used to move heavy components and assemblies during production processes. In metal recycling, these magnets are essential for sorting and transferring scrap metal efficiently. Furthermore, in construction, they assist in handling steel beams and plates safely.

In addition, the advent of advanced technologies, such as robotics, has further expanded the utilization of lifting magnets. Automated systems equipped with these magnets can execute complex tasks, enhancing operational efficiency and safety in environments that require precision and speed.

Conclusion

Industrial lifting magnets play a crucial role in modern manufacturing and construction processes. Their ability to safely and efficiently lift heavy metallic objects has transformed material handling practices. As technology continues to evolve, we can expect to see even greater advancements in magnet design and application, further enhancing their utility in various industries. Embracing these innovative tools not only optimizes operations but also fosters a safer work environment, ultimately contributing to the bottom line of businesses.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025