Powerful Lifting Magnet Designed for Heavy Loads Up to 500 Kilograms in Industrial Applications

The Versatility and Importance of Lifting Magnets A Focus on 500kg Models

In the realm of industrial lifting solutions, lifting magnets have emerged as essential tools that improve efficiency, safety, and productivity. Among the various capacities available, 500kg lifting magnets stand out for their versatility and effectiveness in handling ferrous materials. As industries strive for enhanced operational efficiency, the significant advantages of these lifting devices cannot be overlooked.

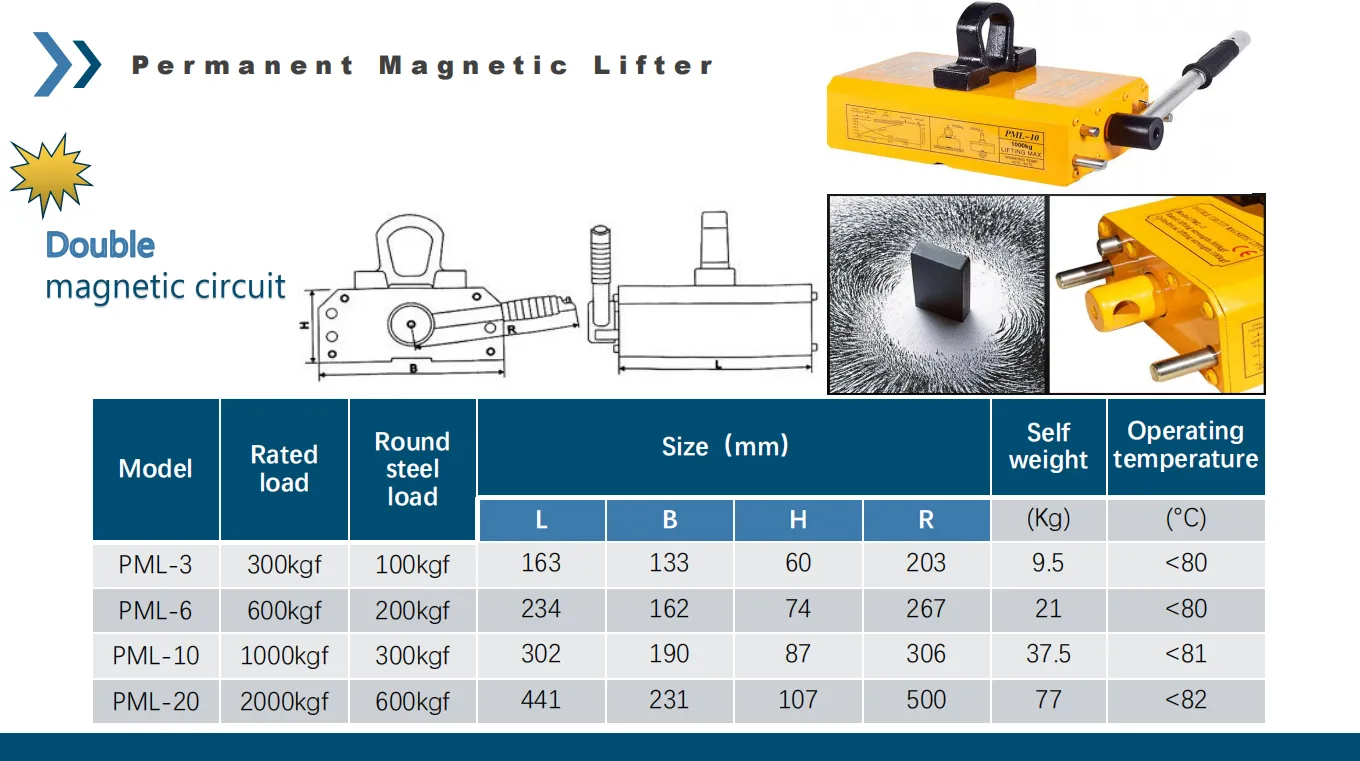

Lifting magnets operate on the principle of magnetism to securely hold and lift heavy metal objects. Designed using advanced magnetic technology, they can bear substantial weights without causing damage to the materials being lifted. A 500kg lifting magnet is specifically tailored for applications that require moving substantial loads, making it an invaluable asset in warehouses, manufacturing plants, and construction sites.

The Versatility and Importance of Lifting Magnets A Focus on 500kg Models

Moreover, using lifting magnets can significantly reduce labor costs and time. Manual lifting and positioning of heavy objects often require a team of workers, leading to increased manpower costs and potential delays. In contrast, a 500kg lifting magnet can typically be operated by a single individual, simplifying the lifting process and contributing to quicker turnaround times. This efficiency makes it a popular choice in environments where time is of the essence, such as assembly lines or during large-scale manufacturing processes.

lifting magnet 500kg

The convenience of lifting magnets extends beyond safety and labor efficiency. They are designed for ease of use, often featuring simple on/off controls that allow for quick engagement and release of loads. This operational simplicity enables workers to focus on the task at hand without being bogged down by complex procedures. Additionally, many models are equipped with safety features such as indicators that show whether the magnet is engaged and secure, further enhancing user confidence.

Environmental considerations are also a growing factor in the choice of lifting equipment. As industries strive to reduce their carbon footprint, electric lifting magnets present a greener alternative to some traditional lifting methods. They operate on electricity rather than hydraulic systems or diesel power, helping to cut down emissions and noise pollution in the workplace.

However, it is essential to ensure that lifting magnets are used in compliance with safety standards and operational guidelines. Operators must be trained to use the equipment properly and assess the material's grade and thickness before lifting, as not all ferrous materials are suitable for all types of magnets. Regular maintenance and inspections of the lifting magnets are equally important to ensure their efficient and safe operation.

In conclusion, the 500kg lifting magnet represents a remarkable fusion of safety, efficiency, and user-friendliness. Its wide range of applications and ease of use make it a critical component in modern industrial operations, helping to redefine materials handling processes. As industries evolve and seek more effective solutions, lifting magnets will undoubtedly continue to play an integral role in the future of manufacturing, construction, and beyond, ensuring that heavy lifting is no longer a burden but a streamlined operation.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025