Powerful Magnetic Hand Lifter for Effortless Transportation of Heavy Metal Objects and Materials

The Magnetic Hand Lifter Revolutionizing Material Handling

In the fast-paced world of manufacturing and construction, efficiency and safety are paramount. As industries gravitate towards enhancing their workflows, innovative tools like the magnetic hand lifter have emerged as game-changers. This article explores what magnetic hand lifters are, their advantages, applications, and their future in material handling.

What is a Magnetic Hand Lifter?

A magnetic hand lifter is a device designed to handle ferromagnetic materials using magnetic force. It typically consists of a powerful magnet, a handle, and a release mechanism. The core idea is simple when the magnet is activated, it adheres to metal objects, enabling users to lift, transport, and reposition heavy materials effortlessly.

Advantages of Magnetic Hand Lifters

1. Safety and Ergonomics The primary benefit of using a magnetic hand lifter is enhanced safety. Traditional methods of lifting heavy materials often lead to workplace injuries due to strains or accidents. Magnetic lifters minimize the risk since they require less physical effort and reduce the chances of dropping heavy items.

2. Efficiency These devices streamline operations significantly. By allowing one person to lift materials that would typically require a two- or three-person team, magnetic hand lifters not only save time but also enhance productivity. The ability to quickly and easily move items enhances workflow, ensuring that tasks are completed on schedule.

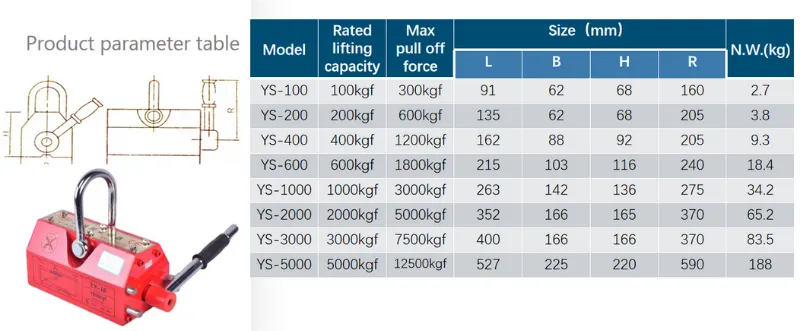

3. Versatility Magnetic hand lifters come in various sizes and strengths, making them suitable for a wide range of applications. From moving steel sheets in factories to assisting in the assembly of large structures, these lifters can handle various ferrous materials, proving their versatility in different settings.

4. Cost-Effective Implementing magnetic lifters can result in significant cost savings for businesses. By reducing labor costs, minimizing workman’s compensation claims associated with injuries, and speeding up material handling processes, these devices represent a worthwhile investment.

magnetic hand lifter

Applications of Magnetic Hand Lifters

Magnetic hand lifters are widely used across different industries. In manufacturing, they facilitate the movement of steel plates, blocks, and machinery components. In construction, they enable workers to lift beams and other heavy items, promoting safer job sites. Additionally, they are invaluable in warehouses and shipping yards for loading and unloading shipments efficiently.

Furthermore, the automotive industry utilizes magnetic lifters in assembly lines, where quick and safe handling of metal parts is essential. Such devices are also beneficial in demolition and salvage operations, where large metal objects need to be handled effectively.

The Future of Magnetic Hand Lifters

As technology continues to advance, the future of magnetic hand lifters looks bright. Innovative designs, including more compact and stronger magnets, smart technologies, and automation integration, are on the horizon. Developments such as Bluetooth connectivity can allow users to monitor the load and track usage data, enhancing operational efficiency.

Moreover, as industries become increasingly focused on sustainability, magnetic lifters that are energy-efficient and made from recyclable materials will likely emerge. This trend aligns with the growing emphasis on reducing carbon footprints in manufacturing and construction.

Conclusion

The magnetic hand lifter is not just a tool; it’s a symbol of innovation and progress in material handling. Offering substantial benefits in safety, efficiency, and versatility, these devices are changing the landscape of numerous industries. As technology continues to evolve, we expect to see even more advancements that will enhance their functionality, making them indispensable in modern workplaces. In a world striving for greater efficiency and safety, magnetic hand lifters are paving the way for a brighter future in material handling solutions.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025