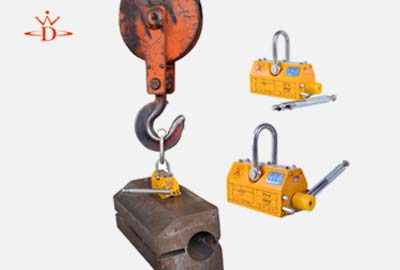

Powerful Magnetic Lifter Capable of Handling Loads Up to 500kg for Industrial Applications

The Utility of Magnetic Lifters A Look at the 500kg Model

In the realm of industrial lifting solutions, magnetic lifters have emerged as an effective means to handle heavy loads with ease and precision. Specifically, the 500kg magnetic lifter has garnered significant attention for its robustness and versatility in various applications. This article delves into the advantages and functionalities of the 500kg magnetic lifter, its working principles, and its applications across different industries.

Understanding Magnetic Lifters

At its core, a magnetic lifter is an innovative device designed to lift ferromagnetic materials using magnetic force. The mechanism consists of a heavy-duty magnet that can be turned on or off to facilitate easy attachment and detachment of objects. This forms the basis for its application in warehouses, manufacturing plants, and construction sites, where efficiency and safety are paramount.

How the 500kg Magnetic Lifter Works

The 500kg magnetic lifter operates by employing an electromagnetic force generated by an electric current passing through coils of wire wrapped around a ferromagnetic core. When the electric current is activated, the lifter's magnet creates a strong magnetic field, which securely holds onto the metal objects. The lifter also features a safety release mechanism that ensures safe detachment, preventing any accidental drops during operation.

This model is particularly effective for lifting steel plates, rods, and other ferrous materials. The ability of the magnetic lifter to engage and release is especially beneficial for workers who are tasked with moving heavy items. With a weight capacity of 500kg, this lifter is suitable for heavy-duty applications, striking a balance between power and portability.

Advantages of the 500kg Magnetic Lifter

magnetic lifter 500kg

1. Efficiency One of the primary benefits of using a magnetic lifter is the speed and efficiency it brings to material handling. Traditional lifting methods often require multiple workers and excessive rigging equipment. In contrast, a magnetic lifter can be operated by a single operator, thus minimizing labor costs and time spent on moving materials.

2. Safety Safety is a critical consideration in any industrial setting. Magnetic lifters are designed with safety features that prevent accidental disengagement. The lifter's design allows for a wider area of contact with the material, distributing weight evenly and reducing the risk of slippage.

3. Versatility The 500kg magnetic lifter is suitable for a variety of applications. From construction sites to metal fabrication shops, it can be used to lift and transport metal sheets, machinery parts, and various other ferrous items. This versatility makes it an indispensable tool in the toolkit of any industrial operator.

4. Low Maintenance Magnetic lifters are generally low-maintenance devices. With no moving parts in the magnetic assembly, they require minimal upkeep compared to traditional lifting mechanisms such as cranes and hoists. Routine inspections and cleaning are typically sufficient to keep the lifter functioning optimally.

5. Cost-Effectiveness While the initial investment in a magnetic lifter may be higher than traditional lifting equipment, the long-term savings in labor and maintenance costs can be significant. The efficiency gains afforded by the lifter can also lead to increased productivity, making it a wise investment for businesses.

Conclusion

The 500kg magnetic lifter stands as a testament to innovative engineering solutions designed to enhance material handling capabilities. With its unique ability to handle heavy loads safely and efficiently, it addresses the demands of modern industrial environments. As technology continues to evolve, magnetic lifters are likely to become even more integral to operating efficiently and safely in various sectors. For businesses seeking to increase productivity while prioritizing worker safety, investing in a 500kg magnetic lifter could be a game-changing decision.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025