Heavy Equipment Rigging and Transportation Solutions for Efficient Machinery Movers

Rigging and Machinery Movers An Overview

Rigging and machinery moving play a crucial role in various industrial sectors, ranging from manufacturing and construction to entertainment and telecommunications. This specialized field focuses on the safe and efficient transportation, installation, and maintenance of heavy machinery and equipment. With advancements in technology and techniques, the rigging industry has evolved to meet the increasing demands of modern operations, ensuring safety, efficiency, and cost-effectiveness.

Understanding Rigging

Rigging refers to the process of setting up equipment, such as ropes, chains, and hoists, to lift and move heavy loads. It requires a thorough understanding of physics, engineering principles, and safety regulations. Riggers must be highly skilled and trained professionals who can assess the weight of the load, determine the best lifting points, and select the appropriate equipment for the job. This ensures that heavy machinery is moved safely without risk of accidents or damage.

The Role of Machinery Movers

Machinery movers are responsible for the transport and relocation of large and heavy equipment. They utilize various techniques and tools to move machinery from one location to another, whether within a facility or across long distances. Their work often includes disassembling and reassembling equipment, ensuring that all parts are safely transported and set up in their new location. Machinery movers play a vital role in industries where equipment needs to be frequently relocated, such as manufacturing plants, warehouses, and construction sites.

Safety Standards and Regulations

Safety is paramount in rigging and machinery moving operations. Professionals in this field must adhere to strict safety standards and guidelines set forth by governing bodies such as the Occupational Safety and Health Administration (OSHA) in the United States. These regulations include proper training for rigging personnel, using appropriate personal protective equipment (PPE), and conducting regular inspections of rigging equipment. Failure to comply with safety standards can result in serious injuries, fatalities, and costly fines for companies.

rigging and machinery movers

Tools and Equipment Used in Rigging and Moving

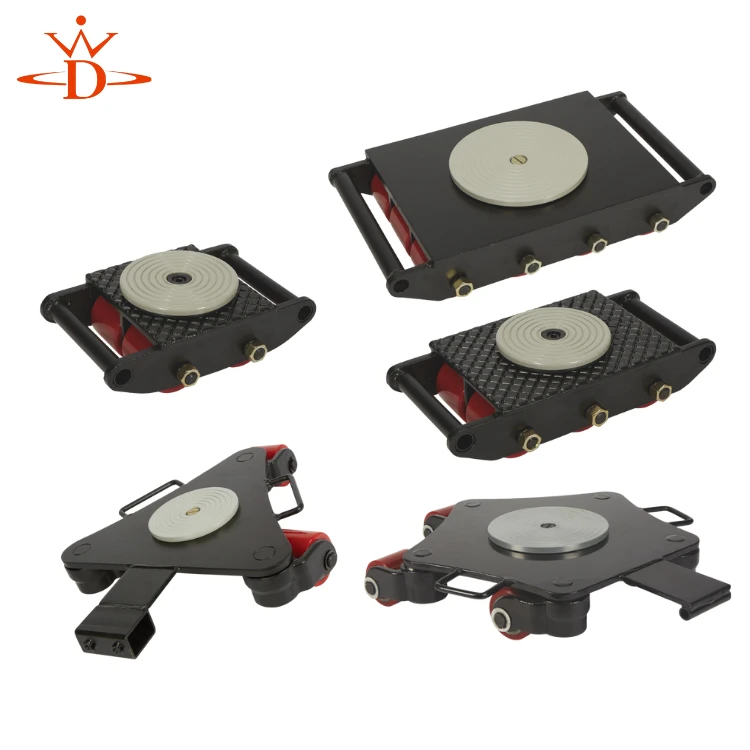

The rigging and machinery moving industry employs a wide range of tools and equipment. Common rigging tools include slings, shackles, hoists, cranes, and pulleys. Each tool serves a specific purpose and must be selected based on the type and weight of the load being moved. For machinery moving, heavy-duty dollies, forklifts, and hydraulic jacks are often used to assist with the transportation and placement of equipment. Advanced technology has also introduced robotic tools and automated systems, enhancing the efficiency and safety of moving heavy machinery.

The Importance of Planning

Effective planning is essential for successful rigging and machinery moving operations. This includes conducting a thorough site assessment, evaluating the machinery's weight and dimensions, and outlining the best path for transportation. Proper planning helps to minimize risks of accidents, delays, and damage to the equipment. Rigging professionals often create detailed lift plans, which include diagrams, equipment lists, and safety measures to follow during the operation.

The Future of Rigging and Machinery Moving

As industries continue to evolve, so do the demands placed on rigging and machinery moving professionals. Technological advancements, like augmented reality (AR) for training and virtual simulation for planning, are becoming increasingly integrated into the industry. Additionally, the growing emphasis on sustainability is influencing the types of machinery used, leading to innovations in lighter and more efficient equipment.

In conclusion, rigging and machinery moving is a vital industry that ensures the safe transport and installation of heavy equipment across various sectors. By adhering to strict safety regulations, employing skilled professionals, and utilizing advanced tools and technology, businesses can efficiently manage their machinery needs while prioritizing safety and productivity.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025