Feb . 17, 2025 20:50

Back to list

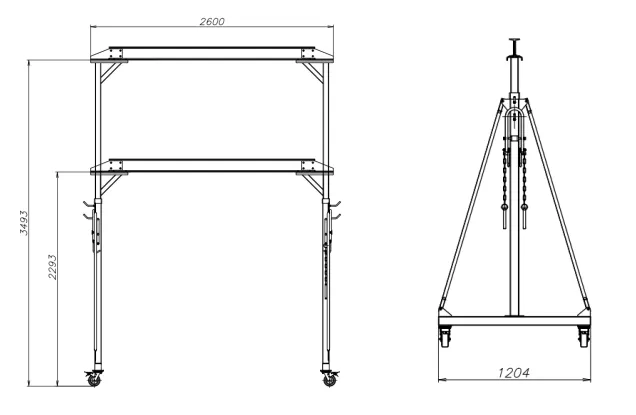

rigging gantry

Navigating the landscape of industrial equipment can be complex, but the rigging gantry stands out as an essential tool in lifting and moving heavy loads with precision and safety. Known for its versatility and reliability, the rigging gantry is crucial in various industries, from construction to manufacturing, playing a pivotal role in enhancing operational efficiency.

Trustworthiness can be further cultivated through the meticulous maintenance and regular inspections of the gantry systems. A well-documented maintenance schedule should be adhered to, with records kept detailing inspections, repairs, and replacements. Avoiding unexpected failures not only ensures the safety of personnel but also stabilizes operational processes, thereby enhancing overall productivity and trust in the use of gantry systems. In the product landscape, technological advances have introduced smart features in rigging gantries, incorporating IoT connectivity for real-time monitoring and diagnostics. These capabilities provide predictive maintenance alerts, minimizing downtime and facilitating immediate decision-making. Investment in these advanced gantries reflects a forward-thinking approach and a commitment to integrating innovation within operational processes. For companies considering the purchase of a rigging gantry, long-term cost implications should be evaluated. Beyond the initial acquisition cost, factors such as maintenance, potential downtimes, and the need for flexibility in operations should be principal considerations. Today’s market offers an array of choices designed to meet diverse business needs, from budget-friendly options for small enterprises to high-tech solutions for industry giants. In closing, the rigging gantry is more than just a piece of equipment; it’s an integral component of the modern industrial ecosystem. Its correct application goes beyond mere mechanical function, requiring an in-depth understanding of operational dynamics, rigorous adherence to safety standards, and strategic foresight. The expertise developed through years of experience in this field can significantly streamline operations, enhance safety, and ultimately act as a cornerstone in the achievement of industrial efficiency and success.

Trustworthiness can be further cultivated through the meticulous maintenance and regular inspections of the gantry systems. A well-documented maintenance schedule should be adhered to, with records kept detailing inspections, repairs, and replacements. Avoiding unexpected failures not only ensures the safety of personnel but also stabilizes operational processes, thereby enhancing overall productivity and trust in the use of gantry systems. In the product landscape, technological advances have introduced smart features in rigging gantries, incorporating IoT connectivity for real-time monitoring and diagnostics. These capabilities provide predictive maintenance alerts, minimizing downtime and facilitating immediate decision-making. Investment in these advanced gantries reflects a forward-thinking approach and a commitment to integrating innovation within operational processes. For companies considering the purchase of a rigging gantry, long-term cost implications should be evaluated. Beyond the initial acquisition cost, factors such as maintenance, potential downtimes, and the need for flexibility in operations should be principal considerations. Today’s market offers an array of choices designed to meet diverse business needs, from budget-friendly options for small enterprises to high-tech solutions for industry giants. In closing, the rigging gantry is more than just a piece of equipment; it’s an integral component of the modern industrial ecosystem. Its correct application goes beyond mere mechanical function, requiring an in-depth understanding of operational dynamics, rigorous adherence to safety standards, and strategic foresight. The expertise developed through years of experience in this field can significantly streamline operations, enhance safety, and ultimately act as a cornerstone in the achievement of industrial efficiency and success.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025