Advanced Technologies in Roller Machinery for Enhanced Production Efficiency

The Role of Roller Machinery in Modern Industries

In today's rapidly evolving industrial landscape, roller machinery has emerged as a pivotal component across various sectors. From construction and manufacturing to agriculture and logistics, roller machinery plays a crucial role in enhancing efficiency, productivity, and safety. This article delves into the significance of roller machinery, its applications, and future trends.

Understanding Roller Machinery

Roller machinery refers to equipment that utilizes rollers for different applications, including material handling, compaction, and processing. Typically, this machinery employs cylindrical rollers that facilitate movement, compression, or shaping of materials. The versatile nature of roller machinery allows it to adapt to various tasks, from creating smooth surfaces to transporting goods effortlessly.

Applications in Different Industries

1. Construction One of the most prominent uses of roller machinery is in the construction industry. Rollers are essential for road construction and maintenance, where they compact soil or asphalt to create stable surfaces. Smooth drum rollers, for example, provide even compaction for roads, while pneumatic rollers are ideal for finishing tasks, ensuring high-quality surfaces that can withstand heavy traffic. Additionally, vibratory rollers use oscillation to enhance the effectiveness of the compaction process.

2. Manufacturing In manufacturing, roller machinery is widely used for transporting materials along production lines. Conveyor systems with roller technology allow for seamless movement of products, optimizing workflow efficiency and reducing labor costs. Roller mills in the food industry, for example, play a critical role in processing grains and other ingredients, ensuring uniformity in texture and quality.

3. Agriculture Roller machinery is also prevalent in agriculture, where it aids in soil preparation and planting. Seedbed rollers, for instance, help in leveling the soil and ensuring optimal conditions for seed germination. Moreover, mulch rollers help in the efficient distribution of organic material, promoting healthy crop growth while reducing weed competition.

4. Logistics and Warehousing In logistics and warehousing, roller conveyors are integral for moving goods quickly across facilities. They minimize manual handling and streamline operations. Automated roller systems further enhance efficiency by allowing for precise control over the movement of products, reducing the risk of damage and improving inventory management.

roller machinery

Advantages of Roller Machinery

The benefits of utilizing roller machinery are numerous. Firstly, it significantly increases efficiency by automating tasks that would otherwise require considerable manual labor. This not only enhances productivity but also reduces the risk of workplace injuries associated with manual handling.

Secondly, roller machinery contributes to cost savings. By improving efficiency, companies can achieve higher output with less labor and energy costs. For example, the use of roller compactors in construction minimizes the need for multiple types of machinery, thereby reducing capital expenditures and maintenance costs.

Moreover, roller machinery enhances precision and quality in manufacturing and construction processes. Improved compaction and material handling techniques result in better-quality products and surfaces, which can lead to reduced rework and higher customer satisfaction.

Future Trends

As technology continues to advance, the future of roller machinery is poised for significant transformation. The integration of smart technology and automation is expected to play a critical role in the evolution of roller machinery. For instance, incorporating sensors and IoT technology will allow for real-time monitoring of equipment performance, predicting maintenance needs, and optimizing operational efficiency.

Sustainability is also becoming a critical factor in the development of roller machinery. Manufacturers are exploring eco-friendly materials and energy-efficient designs to minimize their environmental footprint. As industries move towards greener practices, roller machinery will undergo innovations aimed at meeting these sustainability goals.

Conclusion

Roller machinery is an indispensable part of modern industrial operations. Its versatility and efficiency make it a key player in various sectors, contributing to enhanced productivity and safety. As technological advancements continue to shape the future, roller machinery is set to evolve, incorporating smart technologies and sustainable practices, ensuring that it remains at the forefront of industrial progress. Embracing these innovations will not only benefit businesses but also contribute to a more efficient and sustainable global economy.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

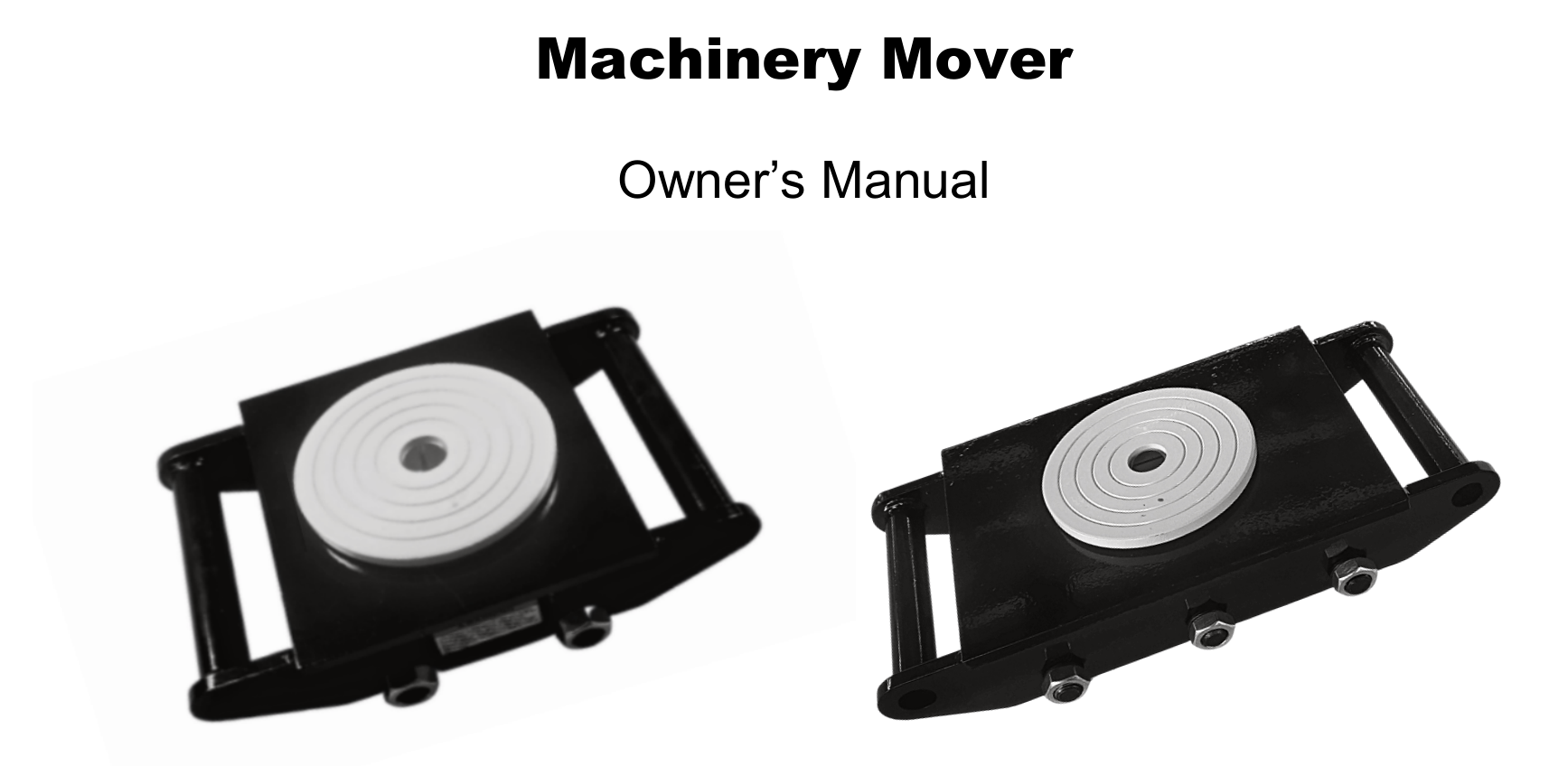

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025