rollers for moving heavy objects

The Benefits of Rollers for Moving Heavy Objects

In various industries and everyday activities, moving heavy objects poses a significant challenge that requires careful consideration and the right tools. Among the various solutions available, rollers have emerged as an effective means to facilitate the movement of heavy items. This article explores the advantages of using rollers for moving heavy objects, highlights their different types, and offers insights into their applications.

Understanding Rollers

Rollers are cylindrical devices that can be placed under heavy objects to allow for easier transport. They come in various sizes, materials, and designs, catering to different weight capacities and types of surfaces. Depending on the specific needs, rollers can be made from rubber, plastic, or metal, each offering unique properties suitable for different environments.

Benefits of Using Rollers

1. Reduced Physical Strain One of the primary advantages of using rollers is the reduction of physical strain on workers. Lifting heavy objects can lead to injuries such as muscle sprains or back problems. By employing rollers, the weight is distributed and the object can be pushed or pulled along the surface, greatly reducing the risk of injury.

2. Increased Efficiency Rollers can significantly enhance productivity. Instead of spending considerable time and effort lifting and carrying heavy items, workers can easily roll objects to their desired location. This efficiency not only speeds up the moving process but also allows staff to focus on other important tasks.

3. Versatility Rollers come in a range of sizes and designs, making them versatile tools for various applications. Whether in a warehouse, construction site, or at home, rollers can handle a broad spectrum of objects, from machinery and furniture to boxes and appliances. This adaptability makes them an invaluable resource in countless settings.

4. Cost-Effectiveness Investing in a set of rollers can be a cost-effective solution for many organizations. The savings associated with reduced labor costs and the decrease in work-related injuries can far outweigh the initial expenditure on equipment. Additionally, the durability of quality rollers means they can last for years, providing long-term value.

rollers for moving heavy objects

5. Surface Protection Many roller designs are made to minimize damage to floor surfaces. For instance, rollers with rubber casters help prevent scratches and dents on hardwood or tiled floors. This is particularly important in commercial settings where maintaining a pristine appearance is crucial for brand image.

Types of Rollers

There are several types of rollers available, each designed for specific needs

- Furniture Rollers These are designed specifically for moving furniture. They are typically small, portable, and easy to use.

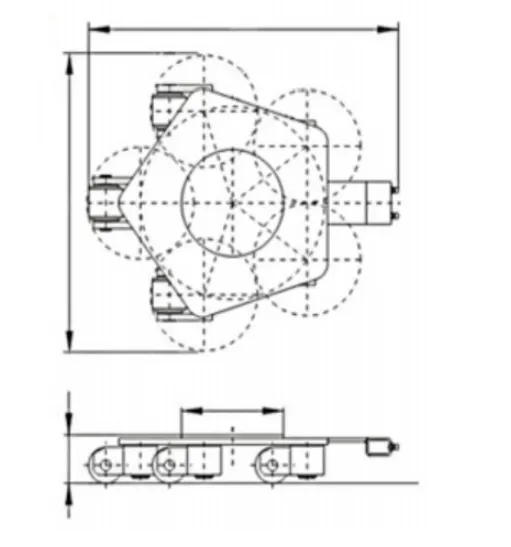

- Machine Rollers For industrial applications, machine rollers are heavy-duty tools that can support significant weights, making them ideal for relocating machinery or heavy equipment.

- Skid Steer Rollers Often used in construction, these rollers can work on rough terrain and are designed to handle larger loads.

- Robot Rollers In the era of automation, robot rollers are emerging in factories, where automated systems transport heavy payloads without human intervention.

Conclusion

In conclusion, rollers serve as an essential tool for moving heavy objects effectively and safely. Their ability to lessen physical strain, increase operational efficiency, and protect surfaces underscores their importance across various applications. With different types available, they can accommodate unique needs in both industrial and personal contexts. As technology continues to evolve, the design and capabilities of rollers are likely to improve, ensuring they remain a staple in the toolkit for moving heavy objects. Embracing this innovative solution not only optimizes workflow but also promotes a safer working environment.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025