Using Rollers for Transporting Heavy Machinery Efficiently and Safely

The Role of Rollers in Moving Heavy Equipment

The movement of heavy equipment is a crucial aspect of construction, mining, and industrial operations. Various methods and tools are employed to facilitate this process, and one particularly effective solution is the use of rollers. Rollers can significantly enhance the efficiency and safety of moving massive loads across various terrains. This article will explore the significance of rollers in transporting heavy equipment, their types, advantages, and best practices for their use.

Understanding Rollers

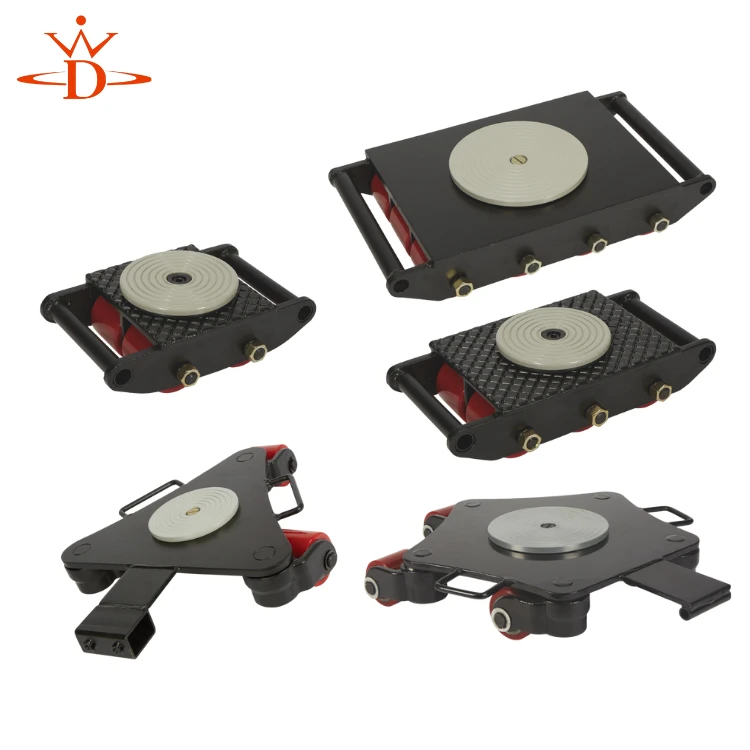

Rollers are cylindrical devices designed to reduce friction, allowing for easier movement of heavy objects. They are widely employed in numerous industries where heavy machinery, such as cranes, excavators, and bulldozers, needs to be relocated. Rollers come in various sizes and materials, making them adaptable to different types of equipment and surfaces.

Types of Rollers

1. Wooden Rollers Traditionally, wooden rollers were commonly used for moving heavy timber or machinery on a flat surface. Although they are still effective, their use has diminished with the advent of more durable materials.

2. Metal Rollers Often made from steel or other durable metals, these rollers are used for moving heavier equipment. They provide a sturdier option and are suitable for various terrains, including rough surfaces.

3. Polyurethane Rollers In recent years, polyurethane has become a popular material for rollers due to its resilience and ability to withstand harsh conditions. These rollers are typically used for transporting delicate or sensitive equipment since they provide better shock absorption.

4. Pneumatic Rollers These are air-filled cylinders designed for transporting exceptionally heavy loads. Pneumatic rollers are often used in industrial settings and can adapt to different surfaces, making them versatile and effective for moving heavy machinery.

Advantages of Using Rollers

The use of rollers to move heavy equipment provides several advantages

1. Reduced Friction Rollers enable smooth movement by reducing the friction between the heavy equipment and the ground. This reduction in friction helps prevent damage to both the equipment and the surface being traversed.

rollers moving heavy equipment

2. Increased Efficiency The ability to move heavy loads with rollers enhances operational efficiency. Workers can transport machinery quicker and with less physical exertion, leading to increased productivity on job sites.

3. Safety Improvements Moving heavy equipment can be dangerous, especially if proper precautions aren't taken. Rollers reduce the risk of accidents by providing a more stable and secure method for moving loads. Additionally, their use can minimize the strain on workers, reducing the likelihood of injuries.

4. Cost-Effectiveness By using rollers, companies can reduce labor costs and time required for transportation. They are often less expensive to implement compared to motorized solutions, making them an economically viable option for many operations.

Best Practices for Using Rollers

While rollers can greatly facilitate the movement of heavy equipment, some best practices should be followed to optimize their use

1. Choose the Right Roller Selecting the appropriate type of roller is crucial based on the load being moved and the surface conditions. Always consider the weight and the material of the equipment to ensure that the rollers can handle the load safely.

2. Maintain the Rollers Regular inspection and maintenance of rollers are essential to ensure they remain in good working condition. Worn-out rollers can break during use, leading to accidents and costly downtime.

3. Train Operators Providing thorough training for workers on how to use rollers safely and effectively is vital. Understanding the proper techniques for moving heavy equipment can minimize risks and enhance efficiency.

4. Plan Transportation Routes Before moving heavy equipment, it is essential to plan the route carefully. Consider obstacles, surface conditions, and the capacity of the rollers to ensure a safe and smooth transfer.

Conclusion

The use of rollers in moving heavy equipment is a practical solution that enhances efficiency and safety in various industries. With different types available and numerous advantages, incorporating rollers into transportation processes can significantly improve operations. Following best practices ensures that their use is effective and contributes positively to the safety and productivity of heavy equipment movement. As businesses continue to seek ways to optimize their operations, the importance of rollers remains clear, highlighting their role as essential tools in modern industrial practices.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025