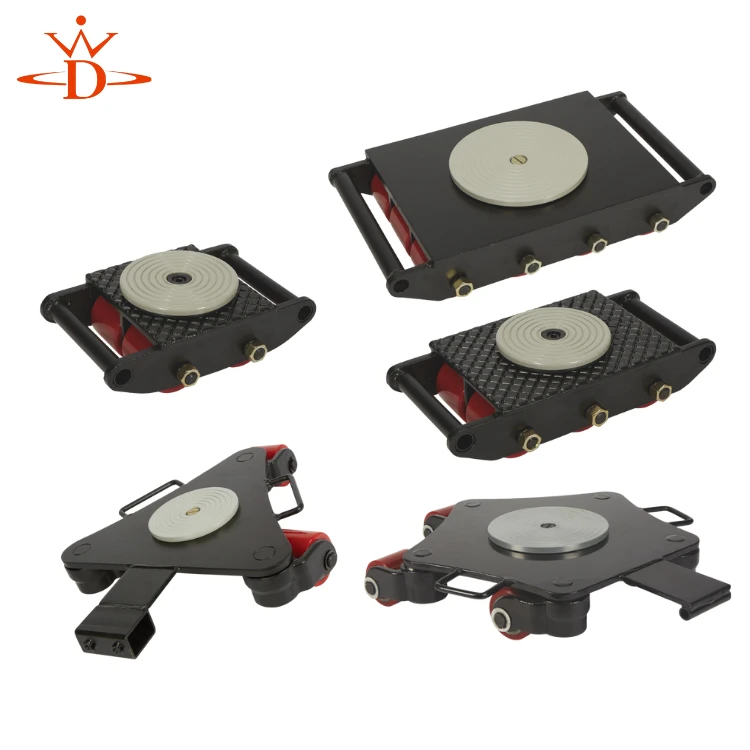

rotating machine skates

Understanding Rotating Machine Skates A Comprehensive Overview

In various industrial settings, heavy machinery and rotating equipment are essential for production and fabrication processes. However, moving such hefty equipment can be a daunting task, potentially causing damage to both the machinery and the facility. This is where rotating machine skates come into play—an innovative solution designed to facilitate the safe and efficient movement of large machines.

Rotating machine skates are specialized devices that allow for the easy movement of heavy equipment, including pumps, generators, and compressors. These skates are engineered to support the weight of the machinery while providing a portable base that can glide across surfaces. The design typically includes multiple wheels or rollers that aid in maneuverability, allowing operators to reposition machines with relative ease.

One of the primary advantages of using rotating machine skates is their ability to simplify the relocation process. Traditional methods often require forklifts, cranes, or extensive labor, which can be inefficient, time-consuming, and even hazardous. With skates, operators can swiftly adjust the position of equipment without excessive effort. This not only saves time but also minimizes the risk of injury associated with handling heavy machinery.

rotating machine skates

The mechanics of rotating machine skates are fascinating. These devices typically include swivel wheels, allowing for 360-degree movement. This feature enables users to navigate around tight corners, doorways, and other obstacles typically encountered in industrial environments. Additionally, many models come with adjustable height settings and locking mechanisms to ensure safety and stability during use. The combination of these elements makes rotating skates an indispensable tool in maintenance, installation, and even repair tasks.

Another critical aspect to consider is the load capacity of machine skates. These devices are built to handle varying weights, from several hundred to several thousand pounds. It's essential for operators to select skates that are compatible with the specific machinery being moved. Choosing the right equipment not only enhances efficiency but also decreases wear and tear on both the skates and the machinery, ultimately extending the lifespan of both.

When using rotating machine skates, safety should remain a top priority. Operators must ensure that the equipment is securely placed on the skates and periodically check for any signs of wear and tear. It is also advisable to train personnel on the proper operation of these devices, as understanding their functionality can prevent accidents and enhance overall workplace safety.

In conclusion, rotating machine skates represent a significant advancement in the field of industrial equipment handling. Their unique design, coupled with modern engineering, allows for the safe and efficient movement of heavy machinery. This innovation not only streamlines operations but also reduces the labor intensity associated with traditional methods. As industries continue to evolve, the role of machine skates will likely become even more pivotal, enabling businesses to enhance productivity while prioritizing safety. Whether in manufacturing, construction, or any sector reliant on heavy machinery, rotating machine skates prove to be an invaluable asset.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025