sheet metal lifting magnets

Sheet Metal Lifting Magnets Enhancing Efficiency in Manufacturing

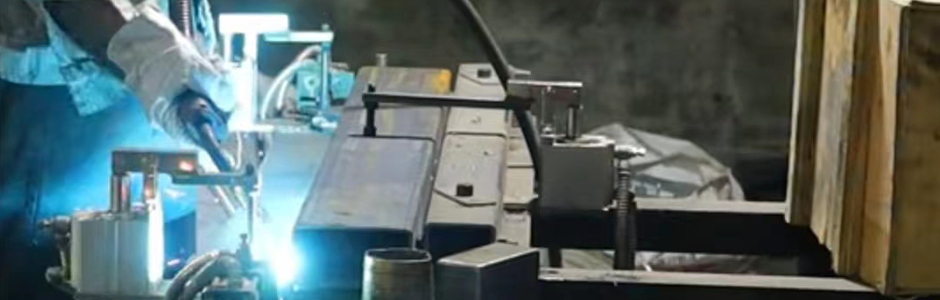

In the world of manufacturing, especially in industries dealing with sheet metal, the efficiency and safety of lifting heavy materials are paramount. Sheet metal lifting magnets have emerged as a critical solution for these challenges, providing a streamlined approach to handling steel and other magnetic materials.

Sheet metal lifting magnets are specially designed devices that utilize magnetic force to lift and move sheet metal. They operate on the principle of electromagnetism, where electric currents create magnetic fields strong enough to lift heavy loads. These magnets can be used on various types of sheet metal, including mild steel, stainless steel, and some other ferromagnetic materials, making them versatile tools in a manufacturing environment.

The primary advantage of using sheet metal lifting magnets is their ability to significantly enhance efficiency during material handling. Traditionally, lifting and moving heavy sheets of metal required the use of cranes, slings, or other mechanical aids, which can be cumbersome and time-consuming. Lifting magnets eliminate the need for these auxiliary devices, allowing for faster movement and placement of materials. This can lead to reduced labor costs and increased productivity on the shop floor.

sheet metal lifting magnets

Safety is another critical aspect where lifting magnets excel. With proper use, they significantly lower the risk of accidents associated with manual handling. The secure grip provided by magnets ensures that sheet metal is moved without the risk of dropping, which could lead to injuries or damage to equipment. Additionally, operators can easily control the lifting and positioning of sheets, which adds an extra layer of safety in a busy manufacturing environment.

Modern sheet metal lifting magnets come equipped with various features to enhance their functionality. Some models are designed with automatic on/off switches, ensuring that the magnetic force is only active when needed. Others may incorporate safety mechanisms that prevent the magnets from releasing their load unintentionally, adding further reliability to their use.

As industries continue to evolve, the reliance on innovative solutions like sheet metal lifting magnets will only increase. Their ability to optimize processes, improve safety, and save time positions them as indispensable tools in the manufacturing sector. Embracing this technology not only helps companies enhance their operational efficiency but also contributes to a safer work environment, aligning with contemporary manufacturing best practices.

In conclusion, sheet metal lifting magnets are revolutionizing the way manufacturers handle heavy materials. Their efficiency, safety features, and ease of use make them essential equipment in a modern manufacturing setup, paving the way for innovation and productivity in the industry.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025