Heavy Duty Magnets for Lifting Sheet Metal Safely and Efficiently

The Importance of Sheet Metal Lifting Magnets in Industrial Applications

In today's fast-paced manufacturing environment, efficiency and safety are paramount. One of the tools that have significantly contributed to enhancing productivity and safety in the handling of heavy materials is the sheet metal lifting magnet. This technology is particularly vital in industries such as automotive, aerospace, and construction, where sheet metal forms the backbone of many structural and functional components.

Understanding Sheet Metal Lifting Magnets

Sheet metal lifting magnets are specialized tools designed to lift and transport sheet metal with ease. These magnets utilize powerful electromagnets or permanent magnets to generate a magnetic field strong enough to hold ferromagnetic materials securely without damaging their surface. The operation of these lifting devices is straightforward; they adhere to metal surfaces, allowing operators to move heavy sheets vertically or horizontally with minimal strain.

Benefits of Using Lifting Magnets

1. Increased Efficiency The traditional methods of lifting and handling sheet metal often involve cumbersome equipment and multiple personnel. Lifting magnets streamline this process, enabling a single operator to manage heavy loads, thereby significantly improving workflow efficiency. This efficiency results in faster production times and reduced operational costs.

2. Enhanced Safety Manual handling of heavy sheet metal poses significant risks to workers, including injuries from awkward lifting or dropping materials. Lifting magnets minimize direct human interaction with heavy loads, reducing the risk of accidents. Additionally, these magnets come with safety features such as safety locks and fail-safes, ensuring that the metal remains secured during transport.

3. Versatility Sheet metal lifting magnets are adaptable for various applications. They can handle different sheet sizes and shapes, making them ideal for diverse industrial settings. Whether you are dealing with thin sheets or heavier plates, the correct magnet can facilitate efficient handling, enhancing operational versatility.

4. Cost-Effectiveness While the initial investment in lifting magnets may seem substantial, the long-term savings they provide can be considerable. Reduced labor costs, fewer workplace injuries, and enhanced operational efficiency lead to improved overall productivity. Companies can quickly recoup their investment through increased output and decreased downtime caused by accidents or inefficiencies.

sheet metal lifting magnets

Types of Sheet Metal Lifting Magnets

There are generally two types of sheet metal lifting magnets permanent magnets and electro-permanent magnets.

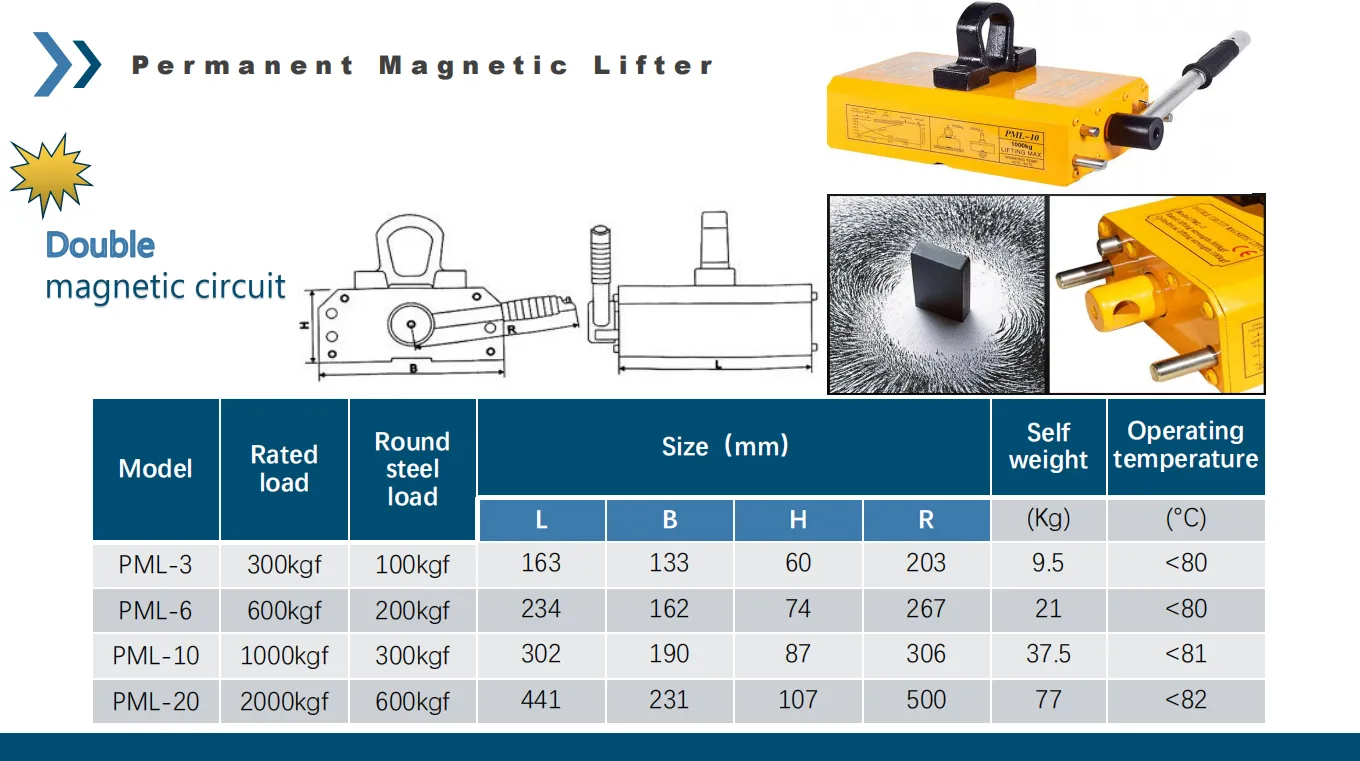

- Permanent Magnets These magnets retain their magnetic properties without the need for an external power source. They are lightweight, require minimal maintenance, and are perfect for environments where power availability might be an issue. However, their lifting capacity may be limited compared to electro-permanent magnets.

- Electro-Permanent Magnets These advanced magnets combine the benefits of both permanent magnets and electromagnets. They can be turned on and off, allowing for flexibility in handling various types of loads. Their magnetic power is often stronger, making them suitable for heavier sheet metal applications.

Future Trends in Magnet Technology

As industries evolve, so do the technologies associated with sheet metal lifting. Innovations in magnet design, such as the development of lighter and more powerful materials, will enhance the functionality of lifting magnets. Integration with IoT (Internet of Things) technology may further improve operational monitoring and safety features, allowing for real-time feedback and enhanced productivity strategies.

Conclusion

Sheet metal lifting magnets are essential tools in modern manufacturing and construction. Their ability to improve efficiency, safety, and cost-effectiveness makes them invaluable in various industrial applications. As technology continues to advance, the potential for these devices will only grow, further revolutionizing the way sheet metal is handled and transported in settings worldwide. Embracing this technology can lead to a safer, more productive workplace, marking a significant step forward in industrial operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025