sheet metal magnetic lifter

Exploring the Benefits and Uses of Sheet Metal Magnetic Lifters

In the world of manufacturing and fabrication, the efficiency and safety of handling heavy materials are paramount. One innovative solution that has revolutionized this process is the sheet metal magnetic lifter. These devices, designed to lift and transport sheet metal safely and effortlessly, have become essential tools in various industries, including construction, automotive, and aerospace.

What is a Sheet Metal Magnetic Lifter?

A sheet metal magnetic lifter is a tool that utilizes powerful magnets to pick up and hold ferromagnetic materials, primarily sheet metal. The lifter operates on the principle of magnetism, allowing it to securely attach to metal surfaces without the need for manual lifting. This not only reduces the physical strain on workers but also increases overall productivity by allowing for quicker and easier movement of heavy materials.

Benefits of Using Magnetic Lifters

1. Enhanced Safety One of the most significant advantages of magnetic lifters is their ability to minimize workplace injuries. Traditional lifting methods often involve manual handling or the use of chains and straps, which can lead to accidents. Magnetic lifters reduce the risk associated with lifting heavy metal sheets, as they secure materials without the need for direct contact.

2. Increased Efficiency Magnetic lifters streamline the process of loading and unloading materials. With their easy-to-use design, operators can quickly attach and detach the lifter from the metal surface, significantly speeding up operations. This efficiency is particularly beneficial in high-paced environments such as factories and construction sites.

3. Versatile Applications Magnetic lifters are suitable for various applications beyond just moving sheet metal. They can be used to handle plates, blocks, and other ferromagnetic materials, making them versatile tools in any workshop. Their adaptability means they can support multiple processes, from assembly lines to maintenance work.

4. Cost-Effective Solutions While the initial investment in a magnetic lifter may be higher than traditional lifting equipment, the long-term savings are considerable. By reducing the likelihood of workplace injuries, decreasing labor costs, and improving movement efficiency, businesses can see a significant return on investment.

sheet metal magnetic lifter

5. Environmentally Friendly As magnetic lifters operate without the need for electricity or fuel, they contribute to a more sustainable operation. Their efficiency means less energy is consumed during transport processes, aligning with modern environmental considerations in manufacturing.

Considerations When Choosing a Magnetic Lifter

When selecting a sheet metal magnetic lifter, it is essential to consider a few key factors

- Capacity Ensure that the lifter can handle the weight of the materials you intend to lift. Magnetic lifters come in various capacities, so choosing one appropriate for your specific applications is crucial.

- Magnet Type There are different types of magnets used in lifters, including permanent magnets and electropermanent magnets. Understanding these differences will help you choose the right device based on your operational needs.

- Safety Features Look for features such as a safety lock system or an indicator for the lifting force. These safety features provide additional security during operation.

- Size and Mobility Consider the dimensions and weight of the lifter itself. A compact and lightweight design may be beneficial for tight spaces or mobile operations.

Conclusion

Sheet metal magnetic lifters are indispensable tools in modern manufacturing and metalworking industries. Their ability to enhance safety, improve efficiency, and provide versatility makes them a valuable addition to any operation. As technology advances, the design and functionality of magnetic lifters continue to evolve, offering even more possibilities for effective material handling. Investing in a quality magnetic lifter can lead to safer and more productive workplaces, ultimately benefiting both the workforce and the bottom line.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

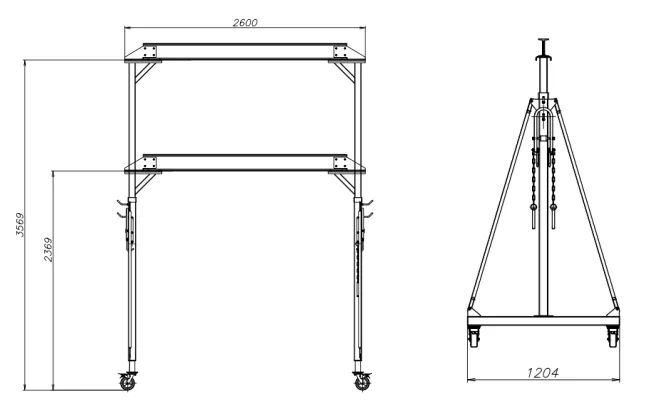

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025