shipping container rollers

Understanding Shipping Container Rollers A Crucial Component in Logistics

In today's fast-paced global economy, efficient logistics management is paramount to maintaining competitive advantage. One essential yet often overlooked component of the shipping process is the shipping container roller. These invaluable devices facilitate the movement of heavy shipping containers, ensuring that the transportation of goods remains smooth and efficient. This article explores the significance, functionality, and advancements in shipping container rollers.

What are Shipping Container Rollers?

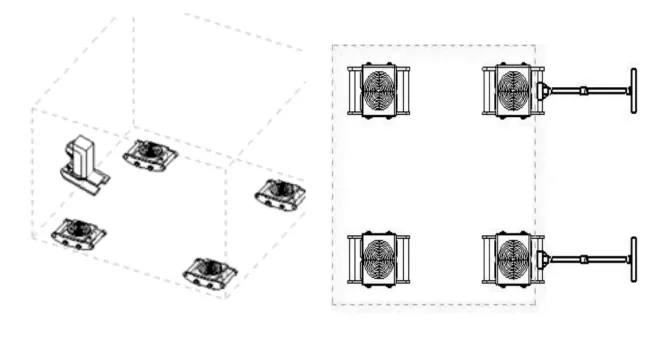

Shipping container rollers are specialized equipment designed to aid in the loading and unloading of shipping containers in ports, warehouses, and distribution centers. They are primarily used to transport containers across various surfaces, enabling logistics personnel to maneuver heavy cargo with minimal effort. These rollers can be either manual or powered, depending on the scale of operation and the weight of the containers involved.

How Do Shipping Container Rollers Work?

The basic function of shipping container rollers is to reduce friction between the container and the ground, allowing for easier movement. Rollers are typically placed beneath the container, allowing it to be easily pushed or pulled by cranes or other lifting equipment. The design of these rollers often includes durable materials that can withstand heavy loads and environmental stressors, such as rust and corrosion.

Most shipping container rollers consist of a series of cylindrical wheels mounted on a frame

. The user places the rollers under the container's corners, and through a combination of manual force or machinery, the container can be shifted into place without the need for extensive manpower or specialized machinery. The roller system not only saves time but also minimizes the risk of injury to workers handling heavy cargo.The Importance of Shipping Container Rollers in Logistics

shipping container rollers

Shipping container rollers play a critical role in optimizing the logistics chain. With the ever-increasing volume of shipping traffic worldwide, quick and efficient movement of cargo is essential. By utilizing rollers, companies can significantly reduce loading and unloading times, leading to faster turnaround of shipments. This efficiency translates to cost savings that can be passed on to customers, creating a competitive edge.

Moreover, manual handling of containers can lead to workplace injuries, resulting in costly downtime and potential liability for companies. Shipping container rollers minimize physical strain on workers by allowing heavier loads to be handled with ease, thereby enhancing workplace safety.

Innovations and Advancements

As technology evolves, so too do shipping container rollers. Recent advancements have seen the introduction of powered rollers that utilize battery or hydraulic systems. These modern rollers are capable of moving containers automatically, further enhancing efficiency and minimizing labor costs. Additionally, some rollers come equipped with sensors that provide real-time data on load weight and distribution, allowing for better logistics planning and equipment utilization.

Sustainability is also becoming a priority within the logistics industry, and manufacturers are responding by creating energy-efficient roller systems and utilizing eco-friendly materials. This focus not only meets regulatory standards but also appeals to environmentally conscious consumers.

Conclusion

Shipping container rollers may not be the most glamorous aspect of the logistics process, but their importance cannot be overstated. As the demand for rapid and efficient shipping continues to grow, the role of these devices becomes increasingly vital. With ongoing innovations in design and technology, shipping container rollers are set to evolve, further enhancing their effectiveness in one of the busiest sectors of the global economy. Understanding their functionality and significance is crucial for anyone involved in the logistics and supply chain management field, as it directly impacts efficiency, safety, and overall operational success. By investing in high-quality roller systems, companies can streamline their processes, reduce costs, and maintain an edge in a competitive marketplace.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025