shipping container rollers

The Essential Role of Shipping Container Rollers in Modern Logistics

In the ever-evolving world of logistics and transportation, efficiency is the key to success. One of the often-overlooked components that plays a crucial role in streamlining the shipping process is the shipping container roller. These specialized devices facilitate the smooth loading and unloading of containers, enhancing operational efficiency and ensuring that goods are transported safely and quickly.

Understanding Shipping Container Rollers

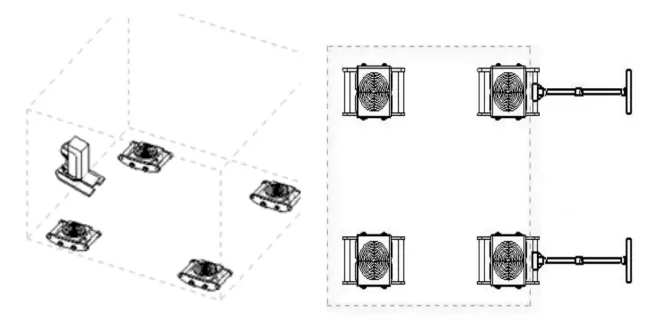

Shipping container rollers, often referred to as container dolly or rollers, are designed to ease the movement of heavy shipping containers. These rollers can be constructed from durable metals or heavy-duty plastic to withstand the weight and impact of containers. They come in various designs tailored to specific needs, whether for manual movement or to be used in conjunction with forklifts and other machinery.

The primary function of shipping container rollers is to reduce friction and make it easier to move containers across surfaces. By lifting a container slightly off the ground, rollers create a line of movement that minimizes the energy required for transportation. This becomes especially important when moving loaded containers, which can weigh several tons.

The Benefits of Using Shipping Container Rollers

1. Increased Efficiency One of the most significant advantages of using shipping container rollers is the enhancement of operational efficiency. With the ability to smoothly transport containers, loaders and unloaders can significantly reduce the time involved in these processes. This, in turn, decreases labor costs and increases the throughput of goods.

shipping container rollers

2. Reduced Risk of Damage Containers are often filled with fragile items that can be easily damaged if subjected to abrupt movements or rough handling. Rollers help absorb some of the shock and provide a gentler way to maneuver containers. This not only protects the cargo but also minimizes wear and tear on the containers themselves.

3. Improved Safety The manual handling of heavy containers poses serious safety risks to workers. By employing shipping container rollers, the need for strenuous lifting and carrying is drastically reduced. This aids in lowering the incidence of workplace injuries, making logistics operations safer for employees.

4. Versatility Shipping container rollers come in various configurations, suitable for different environments and uses. Whether in a dockyard, warehouse, or rail yard, these rollers can be adapted to suit a range of applications. From manually operated models to those compatible with forklifts or automated systems, their versatility allows logistics companies to optimize their operations.

5. Cost-Effectiveness While investing in high-quality shipping container rollers requires upfront capital, the long-term savings and efficiency gains can far outweigh these initial costs. Reduced labor needs, increased speed of operations, and decreased damage rates can lead to significant cost savings over time.

Conclusion

As global trade continues to grow, the demand for efficient shipping methods becomes even more pressing. Shipping container rollers represent a critical yet sometimes overlooked component in the logistics chain. By facilitating the movement of heavy containers, these devices significantly enhance efficiency, reduce the risk of damage, improve safety, and ultimately contribute to a more cost-effective shipping process.

In a world where time is money and customer satisfaction is paramount, investing in shipping container rollers is a smart decision for companies seeking to streamline their logistics operations and maintain a competitive edge. As technology advances and innovation in logistics continues to evolve, shipping container rollers will undoubtedly remain a staple of efficient shipping practices for years to come.

-

Portable 2000 lb Gantry Crane | Heavy-Duty & AdjustableNewsAug.30,2025

-

Versatile Lifting Solutions with Gantry and Overhead CranesNewsAug.29,2025

-

The Versatile Mobile Gantry Crane SolutionNewsAug.29,2025

-

Reliable Movement with Heavy Machinery Skates and RollersNewsAug.29,2025

-

Reliable Lifting Performance with 2000 lb Gantry Crane and 2 Ton Overhead SystemsNewsAug.29,2025

-

Maximize Lifting Efficiency with PML Magnetic LiftersNewsAug.29,2025

-

Efficient Relocation Starts with Reliable Machinery MoversNewsAug.29,2025