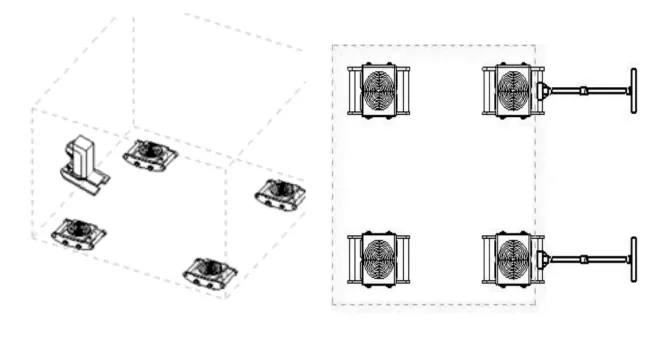

small lifting magnets

The Versatility of Small Lifting Magnets in Modern Applications

Small lifting magnets are versatile tools that have gained prominence in various industrial and commercial applications. Their ability to lift and move metallic objects with ease makes them invaluable in settings ranging from manufacturing to construction. This article explores the functionality, benefits, and uses of small lifting magnets, highlighting their significance in today’s fast-paced environments.

Understanding Small Lifting Magnets

Small lifting magnets, also known as magnetic lifters, utilize the principles of magnetism to achieve lifting capabilities. Typically constructed from high-quality magnetic materials, these devices consist of a ferromagnetic core surrounded by coil windings. When an electric current passes through the coils, a powerful magnetic field is generated, enabling the magnet to securely grip and lift heavy items.

One of the defining features of small lifting magnets is their size. Unlike larger industrial magnets that are designed for heavy-duty applications, small lifting magnets are compact and lightweight, making them easy to handle. They are often equipped with a simple on/off switch, allowing for quick activation and deactivation of the magnetic force, enhancing operational efficiency.

Benefits of Using Small Lifting Magnets

1. Ease of Use Small lifting magnets are user-friendly devices that require minimal training to operate. Their straightforward design allows operators to quickly grab and lift objects without complex procedures, significantly reducing downtime in industrial processes.

2. Safety These magnets offer a safer alternative to traditional lifting methods, such as cranes or hooks. As they can securely hold onto metallic objects without the risk of slipping, they help mitigate accidents and injuries in the workplace.

3. Cost-Effective Solution Small lifting magnets provide an economical option for moving heavy objects. They reduce labor costs by allowing fewer workers to perform tasks that would otherwise require teams, thus streamlining operations and increasing productivity.

4. Versatile Applications These magnets can handle a wide variety of tasks, from lifting steel plates and sections in manufacturing plants to handling metal sheets in warehouses. Their versatility makes them suitable for various industries, including automotive, aerospace, and construction.

small lifting magnets

5. Compact Design The lightweight and compact design of small lifting magnets allows for easy storage and transportation. Operators can carry them around without hassle, making them perfect for mobile applications, such as construction sites or maintenance work.

Applications in Various Industries

1. Manufacturing In manufacturing settings, small lifting magnets are used for transporting components, metal sheets, and machinery parts. Their ability to lift heavy loads without damaging the materials ensures that production lines run smoothly and efficiently.

2. Construction In construction, these magnets assist in the assembly of metal frameworks, beams, and panels. By enabling swift and secure lifting, they contribute to faster project completion times and improve overall workflow on job sites.

3. Maintenance and Repair Maintenance personnel utilize small lifting magnets to assist in repairing and servicing equipment. By easily lifting components for inspection or replacement, they simplify maintenance procedures and reduce the time needed to complete repairs.

4. Scrap Metal Handling Recycling industries benefit from small lifting magnets for moving scrap metal. They can efficiently collect and sort different types of metal, facilitating the recycling process while minimizing physical strain on workers.

5. Art Galleries and Exhibitions Small lifting magnets have also found their way into artistic applications. They are used to hang metal artworks or display items securely, providing a modern aesthetic without compromising on safety.

Conclusion

Small lifting magnets are revolutionary tools that have transformed the way industries handle metal objects. Their ease of use, safety features, and versatility make them essential in various applications, from manufacturing to construction. As technology continues to advance, the efficiency and effectiveness of small lifting magnets are likely to improve, further solidifying their place in modern industrial practices. Whether you’re lifting heavy machinery or displaying artwork, these magnets are undeniably a clever solution to many lifting and handling challenges.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025