Powerful Compact Lifting Magnets for Efficient Material Handling and Heavy Lifting Applications

The Versatility of Small Lifting Magnets A Comprehensive Overview

In the realm of industrial tools and lifting equipment, small lifting magnets have established themselves as an indispensable component across various applications. Compact yet robust, these devices leverage the power of magnetism to offer efficient, safe, and reliable solutions for lifting heavy metal objects. This article will explore the features, applications, and advantages of small lifting magnets, highlighting their significance in modern industry.

What are Small Lifting Magnets?

Small lifting magnets are powerful, compact devices designed for lifting ferrous materials using magnetic force. Made from high-grade materials like neodymium or ceramic, these magnets are engineered to handle significant weight despite their size. Their design typically includes a magnetic base and often features an on/off switch, allowing users to control the magnetic force easily. These magnets come in various shapes and sizes to accommodate different lifting requirements and applications.

Applications of Small Lifting Magnets

The versatility of small lifting magnets makes them suitable for a wide range of applications across different sectors

1. Manufacturing In manufacturing plants, small lifting magnets are used for assembly and handling tasks. They assist in lifting steel plates, pipes, and other components, streamlining the workflow and reducing the risk of injury associated with manual lifting.

2. Metal Recycling Metal recyclers rely heavily on small lifting magnets to efficiently sort and handle scrap metal. Their ability to quickly attract and lift ferrous materials supports recycling efforts, making operations more efficient.

3. Construction In construction, these magnets are used to hold scaffolding and metal forms in place temporarily. They can also assist in lifting heavy tools and equipment, providing safety and convenience on job sites.

4. Art and Decor Beyond industrial use, small lifting magnets find applications in artistic projects. Artists and crafters use them to create interactive displays, allowing for easy assembly and disassembly of art pieces.

small lifting magnets

5. Automotive Industry In the automotive sector, small lifting magnets are employed for tasks such as holding parts in place during assembly and providing support in welding operations, enhancing productivity and precision.

Advantages of Using Small Lifting Magnets

The increasing adoption of small lifting magnets in various industries can be attributed to several advantages they offer

1. Safety One of the most significant benefits of using lifting magnets is the enhanced safety they provide. By eliminating the need for manual lifting of heavy objects, the risk of injury is substantially reduced. This aspect is crucial in environments where heavy lifting is a regular task.

2. Efficiency Small lifting magnets enable faster handling of materials, improving operational efficiency. With a quick-release mechanism, they can lift and drop objects swiftly, significantly speeding up production and handling times.

3. Versatility The adaptability of small lifting magnets is a considerable asset. They can be used on various surfaces and for multiple applications, making them a valuable tool in any workspace.

4. Durability Designed to withstand harsh industrial environments, small lifting magnets boast a long operational life. Their robust construction ensures they perform reliably even under challenging conditions.

5. Cost-Effective By improving operational efficiency and reducing the need for heavy machinery, small lifting magnets can lead to significant cost savings for businesses.

Conclusion

Small lifting magnets are a vital tool in today’s industrial landscape, providing an effective solution for lifting and handling heavy materials across various applications. Their unique combination of safety, efficiency, and versatility makes them attractive to many industries, from manufacturing and construction to recycling and art. As technology evolves, we can expect even more innovative applications and improvements in the design and functionality of these powerful magnets, further cementing their role in modern industrial practices. Whether for everyday tasks or specialized applications, small lifting magnets will undoubtedly continue to play a crucial part in enhancing productivity and safety in the workplace.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

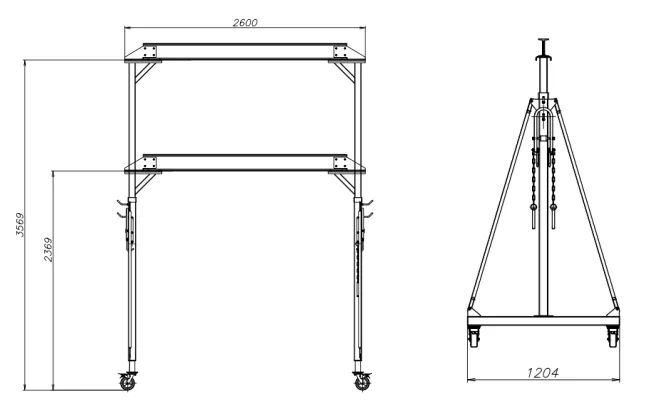

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025