Telescoping Gantry Systems for Enhanced Efficiency and Versatility in Material Handling Applications

The Telescoping Gantry A Modern Ingenious Solution for Heavy Lifting

In the realm of construction, manufacturing, and engineering, the efficiency of lifting and moving heavy materials is paramount. One of the most remarkable innovations to address these challenges is the telescoping gantry, a versatile and ingenious solution designed to enhance operational capabilities across various industries.

What is a Telescoping Gantry?

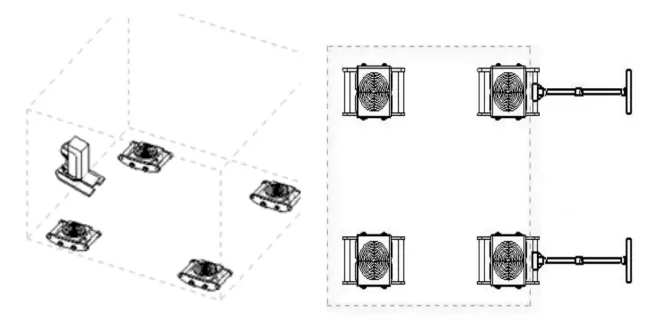

A telescoping gantry is a type of crane system characterized by its ability to extend and retract its arms or legs, allowing for a wide range of motion and adaptability to different lifting scenarios. These gantries are often mounted on wheels or tracks, enabling them to be easily repositioned according to the needs of the job site. The core advantage of telescoping technology is its compact form factor when not in use, allowing for easy transportation and storage without sacrificing functionality.

Key Features and Benefits

1. Space Efficiency One of the standout features of telescoping gantries is their ability to save space. Unlike traditional cranes that occupy significant floor area, a telescoping gantry can minimize its footprint, making it ideal for confined spaces. This is particularly beneficial in urban settings or in facilities with limited maneuverability.

2. Increased Versatility The extendable nature of telescoping gantries allows for a wide variety of lifting heights and distances. This flexibility means that they can effectively handle different types of loads, from large industrial components to smaller, more delicate items, making them a valuable asset in diverse applications.

3. Enhanced Safety Safety is a fundamental consideration in any lifting operation. Telescoping gantries are often built with features that promote secure lifting, including robust locking mechanisms and load sensors. Additionally, operators can control the gantry from a safe distance, minimizing the risk of accidents and injuries on site.

telescoping gantry

4. User-Friendly Operation Modern telescoping gantries are designed with ease of use in mind. They can often be operated with minimal manual effort, using electric or hydraulic systems that provide smooth and precise control. This user-friendly approach can lead to increased productivity and reduced operator fatigue.

5. Cost-Effectiveness While the initial investment in a telescoping gantry may be higher than that of traditional lifting equipment, the long-term savings associated with its versatility and efficiency cannot be overlooked. The reduction in manpower, safety risks, and time spent on lifting tasks can lead to substantial cost savings over time.

Applications Across Industries

The applications for telescoping gantries are vast, spanning various sectors. In construction, they are invaluable for erecting steel frameworks and positioning heavy machinery. In manufacturing, telescoping gantries are commonly used for material handling and assembly line operations. The automotive industry also leverages these cranes to install engines and components in vehicles, showcasing their adaptability.

Furthermore, they play a crucial role in maintenance and repair operations, allowing technicians to lift equipment efficiently without the need for larger, less maneuverable cranes. This flexibility is increasingly important as industries move towards more compact and specialized work environments.

Conclusion

In conclusion, the telescoping gantry represents a significant advancement in lifting technology, offering a combination of efficiency, safety, and versatility. As industries continue to evolve and face new challenges, innovations like the telescoping gantry will undoubtedly play a critical role in optimizing operations and enhancing productivity. Whether in construction, manufacturing, or maintenance, the telescoping gantry stands out as a testament to modern engineering excellence and its capacity to meet the demands of a dynamic work environment.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025