Telescope Style Gantry for Efficient Material Handling and Precision Movement in Industrial Applications

The Telescoping Gantry Revolutionizing Material Handling

In the realm of industrial automation and material handling, the telescoping gantry system has emerged as a game-changer. This innovative equipment provides flexibility, efficiency, and precision, making it an indispensable tool in various sectors including manufacturing, shipping, and construction.

What is a Telescoping Gantry?

A telescoping gantry is a type of material handling equipment that features a movable arm capable of extending and retracting. This mechanism allows the gantry to adjust its reach and height according to the needs of the operation. Typically constructed from high-strength materials like steel or aluminum, these gantries are designed to support heavy loads while maintaining stability and safety.

The core design of a telescoping gantry consists of a frame, a lifting mechanism, and an extending arm. The frame generally rests on wheels or tracks, enabling movement from one location to another. The lifting mechanism—often hydraulic or electric—enables vertical movement, while the telescoping arm adjusts both horizontally and vertically to access different heights and distances. This versatility is what sets telescoping gantries apart from traditional fixed or static cranes.

Key Advantages

1. Space Efficiency Unlike traditional cranes that require substantial space for operation, telescoping gantries can be adjusted to fit into tighter spaces. This capability makes them ideal for warehouses and manufacturing plants with limited floor space.

2. Flexible Operation The ability to extend and retract allows for operations in various configurations. Whether lifting materials from a truck bed or moving loads within a factory, this flexibility enhances operational efficiency.

3. Improved Safety Safety is paramount in any industrial setting. Telescoping gantries reduce the risks associated with manual handling and heavy lifting by mechanizing the process. Moreover, many models come equipped with safety features such as overload protection and emergency stop buttons.

telescoping gantry

4. Cost-Effective While the initial investment in a telescoping gantry system may be higher than traditional equipment, the long-term savings on labor costs and increased productivity often justify the expense. By automating material handling processes, companies can allocate their workforce more effectively.

Applications Across Industries

The versatility of telescoping gantries allows them to be utilized in various industries. In manufacturing, these systems are employed for loading and unloading heavy machinery or materials from assembly lines. In construction, they facilitate the movement of building materials to elevated work sites, enabling quicker project turnaround times.

Additionally, the shipping industry benefits from the use of telescoping gantries for container handling. Their flexibility allows for quick adjustments when loading or unloading containers of various sizes and weights, leading to efficient operations in busy ports and shipping yards.

Future Innovations

As technology continues to advance, the design and functionality of telescoping gantries are likely to evolve. Integration with smart technology, such as IoT (Internet of Things) connectivity, could allow for real-time tracking and monitoring of material handling processes. Moreover, advancements in automation and robotics could further enhance their efficiency and usability, paving the way for fully automated material handling systems.

Conclusion

The telescoping gantry is more than just a piece of equipment; it represents the future of material handling. Its ability to adapt to various tasks, improve safety, and enhance efficiency makes it an essential tool in modern industrial operations. As industries continue to seek out innovative solutions, the telescoping gantry is poised to lead the way in creating smarter, more efficient workplaces. As businesses invest in such technology, they not only improve their operations but also set the stage for sustainable growth in an ever-evolving marketplace.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

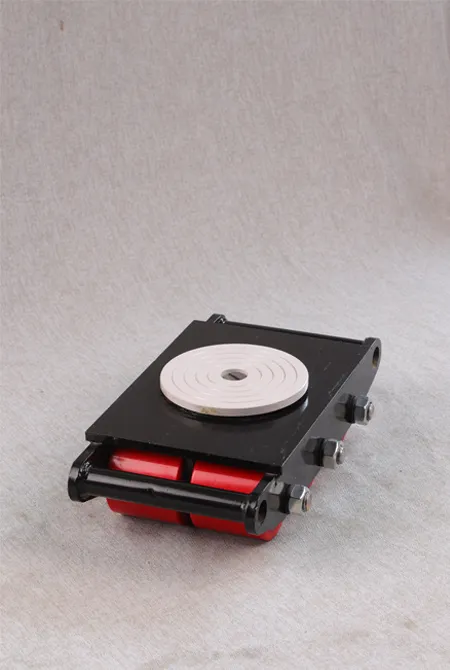

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025