travelling gantry

The Marvels of Travelling Gantries A Blend of Engineering and Technology

In the realm of construction and heavy engineering, few innovations are as fascinating as the travelling gantry

. This versatile piece of equipment exemplifies the fusion of technology and engineering, enabling the seamless movement of heavy loads across vast worksites. The travelling gantry is not just a tool; it is a crucial element that drives productivity and safety in various industries, from shipbuilding to bridge construction and beyond.At its core, a travelling gantry is a crane-like structure that spans a workspace, designed to move along a set of tracks or a defined path. It consists of a bridge that is supported by two legs, and the entire assembly can traverse a designated area, allowing for efficient lifting and transporting of materials. The gantry's design can vary significantly based on its intended application, but the principles of operation remain largely the same.

One of the key advantages of travelling gantries is their ability to handle large and heavy loads. In shipyards, for example, gantries facilitate the construction and maintenance of vessels that can weigh thousands of tons. The gantry moves over the ship, effortlessly lifting heavy components such as engines, hull sections, and electronics, all while ensuring precision placement. This capability drastically reduces the time and labor involved in shipbuilding processes, contributing to faster project completions and cost efficiencies.

Moreover, travelling gantries can also be adapted for the construction of large-scale infrastructure projects, such as bridges and skyscrapers. In bridge construction, gantries are often employed to lift and position massive girders and beams, ensuring they are securely placed for optimal structural integrity. The flexibility of the travelling gantry allows workers to access areas that might otherwise be challenging to reach, enhancing both safety and accessibility.

travelling gantry

Safety is an essential aspect of any construction project, and the use of travelling gantries has significantly improved safety standards in the industry. By automating the lifting and moving of heavy materials, the risk of accidents related to manual handling is greatly reduced. Operators can control the gantry from a safe distance, minimizing their exposure to hazardous conditions on-site. Additionally, many modern gantries are equipped with advanced sensors and monitoring systems, providing real-time data on load weights and movements, further enhancing safety.

Technological advancements have also played a crucial role in the evolution of travelling gantries. The integration of robotics and artificial intelligence into gantry systems has led to increased efficiency and precision. For instance, some modern travelling gantries are capable of performing intricate movements with minimal human intervention, reducing the risk of errors that could compromise safety or project timelines. Remote-controlled systems and automated tracking mechanisms ensure that loads are moved accurately without the need for extensive manual input.

The environmental implications of travelling gantries are also noteworthy. With a focus on sustainability, many construction firms are turning to electric or hybrid gantries, reducing carbon emissions and noise pollution on worksites. This shift not only adheres to global sustainability goals but also creates a more favorable work environment for employees.

In conclusion, travelling gantries represent a remarkable convergence of engineering prowess and technological advancement. As they continue to evolve, these structures will undoubtedly play an increasingly vital role in shaping the future of construction and heavy industry. Their ability to enhance productivity, ensure safety, and contribute to sustainable practices marks them as indispensable tools in the modern industrial landscape. As projects become more complex and demanding, the importance of travelling gantries will only continue to grow, standing as a testament to human ingenuity and the pursuit of excellence in engineering.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

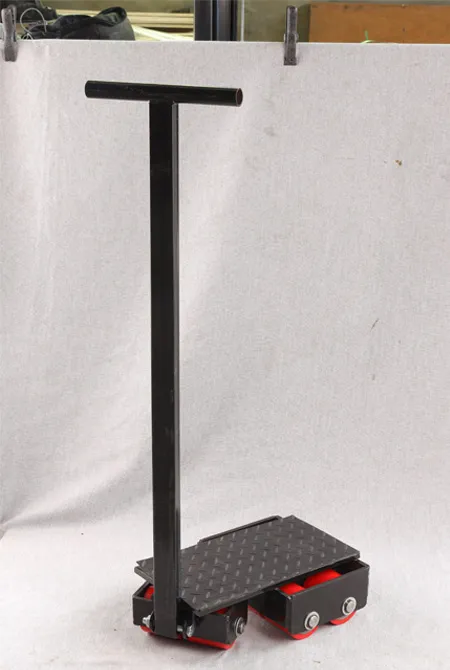

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025