Feb . 17, 2025 20:23

Back to list

types of gantry cranes

Gantry cranes are an essential part of many industrial operations, providing the lifting power necessary to move heavy loads with precision and safety. They come in various types, each tailored for specific environments and tasks. This detailed exploration of gantry cranes delves into their different types, highlighting their applications, benefits, and features that distinguish them within the industry.

A specialized type for heavy fabrication and shipyard settings is the Cantilever Gantry Crane. Characterized by its extended arms or 'cantilevers' that project beyond the standard frame, these cranes provide extended lifting capability and reach. This unique feature makes them suitable for applications where overhanging loads need to be managed or where the crane needs to span other obstacles. Cantilever gantry cranes enable the precise handling of large, unwieldy items, boosting productivity and safety in complex lifting scenarios. Rail-Mounted Gantry Cranes (RMGs) are predominant in container handling and freight operations, offering tremendous efficiency and control. Operating on a rail system, these cranes are designed for fast, precise movement, making them ideal for loading and unloading cargo containers in ports and rail terminals. Their substantial lifting capacity and precise control enable quick turnaround times in high-volume environments, optimizing cargo flow and enhancing the efficiency of logistical operations. The Rubber-Tired Gantry Crane (RTG) is another crucial type, especially in ports and intermodal terminals. Unlike RMGs, RTGs move on rubber tires, providing greater mobility and flexibility within the container yard. They can straddle multiple rows of containers, simplifying the stack and retrieval processes. This mobility, combined with their ability to handle large and heavy loads, makes RTG cranes indispensable for maintaining efficiency and organization within high-density container terminals. For smaller operations, the Workshop Gantry Crane provides a cost-effective and efficient lifting solution. These cranes are typically used in light manufacturing, maintenance, or assembly applications, offering the flexibility to move loads within a localized area. Workshop gantry cranes are known for their manageable size and ease of use, making them ideal for small-scale operations where precision and control are essential. Each type of gantry crane is designed to meet specific industrial requirements, highlighting the importance of understanding their features and applications. Choosing the right gantry crane involves assessing several factors, such as load weight, workspace size, and mobility needs, to match the crane's capabilities to operational demands. By tailoring the choice of gantry crane to meet these specific needs, businesses can ensure increased efficiency, safety, and productivity in their lifting operations. As industries continue to advance and environments evolve, the versatility and adaptability of gantry cranes remain a crucial asset in the industrial toolkit.

A specialized type for heavy fabrication and shipyard settings is the Cantilever Gantry Crane. Characterized by its extended arms or 'cantilevers' that project beyond the standard frame, these cranes provide extended lifting capability and reach. This unique feature makes them suitable for applications where overhanging loads need to be managed or where the crane needs to span other obstacles. Cantilever gantry cranes enable the precise handling of large, unwieldy items, boosting productivity and safety in complex lifting scenarios. Rail-Mounted Gantry Cranes (RMGs) are predominant in container handling and freight operations, offering tremendous efficiency and control. Operating on a rail system, these cranes are designed for fast, precise movement, making them ideal for loading and unloading cargo containers in ports and rail terminals. Their substantial lifting capacity and precise control enable quick turnaround times in high-volume environments, optimizing cargo flow and enhancing the efficiency of logistical operations. The Rubber-Tired Gantry Crane (RTG) is another crucial type, especially in ports and intermodal terminals. Unlike RMGs, RTGs move on rubber tires, providing greater mobility and flexibility within the container yard. They can straddle multiple rows of containers, simplifying the stack and retrieval processes. This mobility, combined with their ability to handle large and heavy loads, makes RTG cranes indispensable for maintaining efficiency and organization within high-density container terminals. For smaller operations, the Workshop Gantry Crane provides a cost-effective and efficient lifting solution. These cranes are typically used in light manufacturing, maintenance, or assembly applications, offering the flexibility to move loads within a localized area. Workshop gantry cranes are known for their manageable size and ease of use, making them ideal for small-scale operations where precision and control are essential. Each type of gantry crane is designed to meet specific industrial requirements, highlighting the importance of understanding their features and applications. Choosing the right gantry crane involves assessing several factors, such as load weight, workspace size, and mobility needs, to match the crane's capabilities to operational demands. By tailoring the choice of gantry crane to meet these specific needs, businesses can ensure increased efficiency, safety, and productivity in their lifting operations. As industries continue to advance and environments evolve, the versatility and adaptability of gantry cranes remain a crucial asset in the industrial toolkit.

Next:

Latest news

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

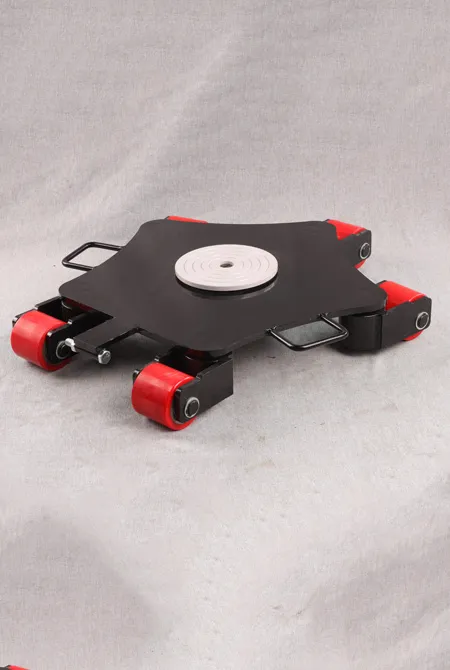

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025