types of gantry girder

Types of Gantry Girders

Gantry girders play a crucial role in the construction and civil engineering sectors, serving as structural support for various systems, including cranes and bridges. Understanding the different types of gantry girders is vital for engineers, designers, and construction teams to ensure the appropriate design is implemented for specific applications.

1. Single Girder Gantry Crane This is the most basic type of gantry girder. It features a single beam that supports the hoisting mechanism. Single girder gantry cranes are lightweight and ideal for lifting moderate loads at low heights, making them suitable for smaller workshops or storage areas.

Types of Gantry Girders

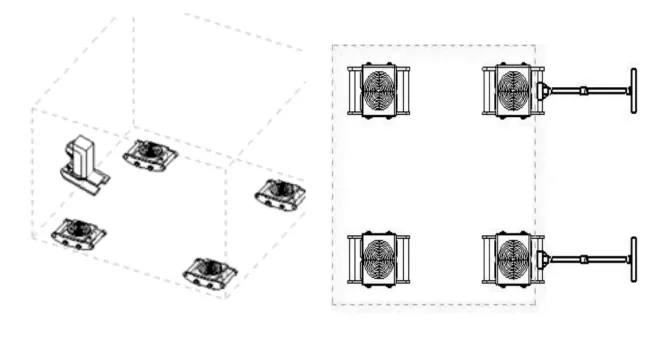

3. Rubber-Tired Gantry (RTG) Crane Commonly used in container terminals, RTG cranes are mobile and operate on rubber tires. This flexibility allows them to move containers quickly across a yard without the need for fixed rail systems. They are particularly effective in environments requiring high-density stacking and quick transportation.

types of gantry girder

4. Rail Mounted Gantry (RMG) Crane Similar to RTG cranes, RMG cranes are designed to navigate along fixed tracks. They are commonly utilized in ports and rail yards for loading and unloading containers from ships and trains. The rail-mounted system provides stability and accuracy in operations while maximizing space utilization.

5. Cantilever Gantry Crane This type features a cantilevered design that extends one side beyond the supports. This configuration allows for operations close to walls or other structures. Cantilever gantry cranes are widely used in shipyards and construction sites, where space constraints are a factor.

6. Overall Gantry Crane This type incorporates a bridge and a hoist system that can move across a wide span. It is typical for heavy-duty applications, including steel fabrication and large-scale manufacturing, providing excellent load capacity and flexibility in movement.

In conclusion, the choice of gantry girder depends on the specific needs of the project, including load capacity, spatial constraints, and operational requirements. By selecting the appropriate type of gantry girder, construction and engineering teams can enhance efficiency and safety in their operations, ultimately leading to successful project outcomes.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025