Understanding the Key Components and Functionality of Gantry Cranes in Industrial Applications

Understanding Gantry Crane Components

Gantry cranes are a vital piece of equipment in various industries, particularly in construction and manufacturing settings. They serve the essential purpose of lifting and moving heavy loads with precision and safety. Understanding the components of a gantry crane is crucial for optimizing its use and ensuring safe operation. This article will delve into the essential components of a gantry crane and their functions.

1. Gantry Structure

The gantry structure forms the backbone of the crane. Typically constructed from steel, it consists of two vertical legs and a horizontal crossbeam that connects the legs. The design allows the crane to straddle the load, providing stability when lifting heavy items. The legs may have wheels or tracks that enable the crane to move along a predetermined path, allowing for efficient load movement within a workspace.

2

. Hoist MechanismThe hoist mechanism is responsible for lifting and lowering the load. This component usually consists of a motor, gearbox, and lifting medium, such as a chain or wire rope. The motor provides the power necessary to lift heavy loads, while the gearbox controls the lifting speed. Operators can control the hoist via a pendant or remote control for better precision when maneuvering loads.

3. End Trucks

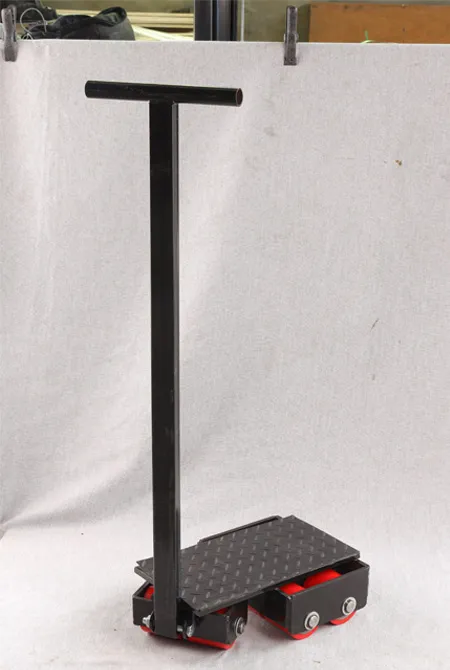

End trucks are the wheeled assemblies located at the base of each vertical leg of the gantry crane. They are critical for providing mobility to the crane. They typically feature rubber or polyurethane wheels that allow for smooth movement along tracks or concrete floors. Depending on the application, end trucks can often be equipped with brakes to ensure stability when the crane is stationary.

4. Control Systems

komponen gantry crane

Modern gantry cranes are equipped with sophisticated control systems. These systems may utilize wired or wireless controls, enabling operators to move the crane and manage the hoist mechanism efficiently. Advanced control systems include safety features, such as overload protection and emergency stop functions, to enhance operator safety.

5. Power Supply

Power supply options for gantry cranes vary depending on their design and intended use. Some cranes operate on electric power, providing a reliable and consistent energy source for heavy lifting tasks. Others may be powered by diesel engines, particularly in outdoor applications or locations without reliable electrical access. Understanding the power requirements is essential when determining the appropriate crane for specific tasks.

6. Safety Features

Safety is paramount in any lifting operation. Gantry cranes are often outfitted with several safety features that protect operators and equipment. These may include limit switches that prevent the hoist from lifting beyond its capacity, emergency stop buttons, and automatic braking systems. Regular maintenance and safety checks are also crucial to ensure that these features are fully operational.

7. Accessories

Various accessories can enhance the functionality of a gantry crane. These may include spreader bars, hooks, and lifting slings, designed to facilitate the secure handling of different types of loads. Selecting the right accessories for specific lifting tasks is vital to ensure safety and efficiency.

Conclusion

Gantry cranes play an indispensable role in modern industrial operations, and understanding their components is crucial for effective use. From the robust gantry structure that provides stability to the various systems that ensure safe lifting, each component works in harmony to perform heavy lifting tasks efficiently. As industries continue to evolve, so will the technology and design of gantry cranes, enhancing their capabilities and the safety standards that accompany them. Proper knowledge of these components not only aids in the effective operation of the crane but also fosters a safer working environment.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025