Versatile Gantry System for Enhanced Flexibility and Efficiency in Operations

The Evolution and Significance of Adjustable Gantries

In the realm of construction and engineering, the term gantry refers to a framework or structure that supports equipment such as cranes, hoists, and other machinery. An adjustable gantry is a specific type of gantry that allows users to modify its height and width according to their operational needs. This versatile equipment has gained prominence in various industries due to its flexibility, efficiency, and safety features.

Design and Functionality

At its core, an adjustable gantry consists of vertical supports, a horizontal beam, and a mobility mechanism, which can be either fixed or wheeled. The adjustable components allow operators to raise or lower the structure's height and change the lateral distance between the supports. This adaptability is particularly crucial in environments where variable load sizes and heights are commonplace, such as in warehouses, factories, and construction sites.

Typically made from robust materials such as steel or aluminum, adjustable gantries are engineered to handle substantial weights. They often come with safety features, including locking mechanisms to ensure stability during operations and limit switches that prevent accidental over-extension. Moreover, the addition of wheels enables easy transportation and repositioning, enhancing their usability in dynamic work environments.

Applications Across Industries

The versatility of adjustable gantries makes them applicable in numerous sectors. In construction, they serve as essential supports for lifting heavy materials or equipment. They facilitate tasks such as beam installation, roof construction, and heavy lifting where traditional cranes might not fit or be practical.

adjustable gantry

In manufacturing, adjustable gantries are used to maneuver parts during assembly, quality control, or repairs. Their adjustable nature allows manufacturers to customize them for specific machinery or processes, thus optimizing the workflow and improving overall productivity. For instance, in an automotive assembly line, an adjustable gantry can easily accommodate various vehicle sizes, making it indispensable in modern production facilities.

Moreover, in event planning and staging, adjustable gantries are used for setting up lighting rigs and high-altitude displays. Their capability to adjust height allows for precise positioning, ensuring that optimal visibility and safety standards are met, whether it's for concerts, exhibitions, or corporate events.

Safety and Regulations

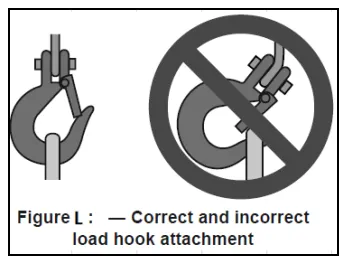

Safety is a paramount consideration in any operation involving heavy lifting equipment, and adjustable gantries are no exception. Industry standards and regulations dictate the design, manufacture, and use of these structures to minimize risks associated with lifting operations. Operators must be adequately trained on the correct use of adjustable gantries, including how to assess load limits and secure the equipment properly. Routine maintenance and inspections are also crucial to ensure the gantry remains in good working condition and adheres to safety regulations.

Future of Adjustable Gantries

As technology continues to advance, the future of adjustable gantries looks promising. Innovations such as smart sensors and remote controls are being integrated into their designs, allowing for more precise adjustments and real-time monitoring of weights and stresses. These technological enhancements promise to improve both efficiency and safety, reducing the risk of human error.

In conclusion, adjustable gantries represent a critical advancement in lifting technology. Their adaptability and multifaceted applications across various industries not only enhance operational efficiency but also contribute to workplace safety. As construction and manufacturing evolve, the importance of such versatile equipment will only continue to grow, paving the way for safer, more efficient work environments.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025