Versatile Heavy Duty Gantry Crane Solutions for Industrial and Construction Applications with Enhanced Performance

Understanding Heavy Duty Gantry Cranes A Key Component in Heavy Lifting

Heavy duty gantry cranes are critical pieces of equipment in industries that require the lifting and moving of extremely heavy loads. Whether used in shipping yards, construction sites, or manufacturing facilities, these cranes provide the necessary strength and versatility to handle substantial weights safely and efficiently. In this article, we will explore the various aspects of heavy duty gantry cranes, including their design, applications, benefits, and maintenance considerations.

Design Features

Heavy duty gantry cranes are designed to support significant loads, often exceeding several tons. Their robust structure typically consists of two vertical supports, known as legs, and a horizontal beam that spans the distance between them. This configuration allows for maximum stability while providing sufficient clearance to move loads beneath the crane. Many gantry cranes utilize a wheeled base that can be moved along a set path, giving them the flexibility to serve multiple work areas.

One of the standout features of heavy duty gantry cranes is their adjustable height and span, which can be modified based on specific operational requirements. Some cranes are even equipped with motorized hoists that can be controlled remotely, enhancing safety by minimizing the need for personnel to be in close proximity to heavy loads while they are lifted.

Applications Across Industries

The versatility of heavy duty gantry cranes allows them to be utilized in a variety of applications

. In the shipping industry, they are commonly employed for loading and unloading containers from ships, facilitating the smooth transfer of cargo. Construction sites benefit from these cranes for lifting steel beams, large machinery, and other heavy construction materials, drastically increasing productivity and efficiency.Manufacturing plants also implement heavy duty gantry cranes in assembly lines, where they assist in transporting heavy components and materials, ultimately streamlining production processes. Additionally, these cranes are invaluable in the aerospace and automotive sectors, where precision and reliability are paramount.

heavy duty gantry crane

Benefits of Heavy Duty Gantry Cranes

There are several advantages to using heavy duty gantry cranes. First and foremost is their remarkable load capacity, which allows for the safe handling of heavy objects that would be impractical for manual lifting. This not only enhances workplace safety by reducing the risk of injury but also increases productivity as more work can be accomplished in less time.

Moreover, the mobility of gantry cranes enables companies to make better use of their space. Rather than relying on fixed cranes that take up valuable real estate, heavy duty gantry cranes can be moved to where they are needed most. This flexibility can lead to significant cost savings by improving the efficiency of operations and reducing the time spent on lifting and moving materials.

Maintenance Considerations

Despite their durability, regular maintenance of heavy duty gantry cranes is essential to ensure safe and efficient operation. Routine inspections should focus on critical components such as the hoist mechanism, wheels, and structural integrity of the crane. Identifying wear and tear early can prevent larger issues down the line and prolong the lifespan of the equipment.

Furthermore, operators should be trained in safe usage practices, including load limits and the importance of having a clear work area. Implementing a comprehensive safety protocol not only protects the equipment but also the workers involved in crane operations.

Conclusion

Heavy duty gantry cranes play a crucial role in various industries by providing an essential means of lifting and moving heavy loads. Their design features, wide-ranging applications, benefits, and maintenance practices all contribute to their reputation as indispensable tools in modern logistics and manufacturing. As technology advances, we can expect to see even more innovative developments in gantry crane systems, further enhancing their efficiency, safety, and versatility in heavy lifting tasks.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

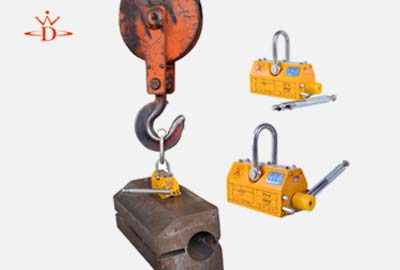

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025