Versatile Magnetic Lifter for Efficient Lifting Solutions in Industrial and Construction Applications

The Portable Magnetic Lifter An Essential Tool for Industrial Efficiency

In the world of modern industry, efficiency and safety are paramount. One tool that has been gaining popularity for its effectiveness and utility is the portable magnetic lifter. Designed to simplify material handling in factories, warehouses, and construction sites, this innovative device has transformed the way heavy metals and other ferromagnetic materials are moved.

What is a Portable Magnetic Lifter?

A portable magnetic lifter, as the name suggests, is a device that employs powerful magnets to lift and carry heavy objects. These lifters utilize permanent magnets, meaning they can hold heavy loads without the need for an external power source. The design typically consists of a robust casing containing the magnet, a lifting handle, and a release mechanism. They come in various sizes and lifting capacities, making them suitable for a wide range of applications.

How Does It Work?

The operation of a portable magnetic lifter is straightforward. When the lift is placed on a ferromagnetic surface, such as steel, the permanent magnet generates a strong magnetic field that adheres to the metal. By pulling a lever or pressing a button on the device, the operator can engage or disengage the lifting mechanism. This feature allows users to easily lift and lower loads without the need for complex rigging equipment or additional labor, thereby streamlining operations.

Applications Across Industries

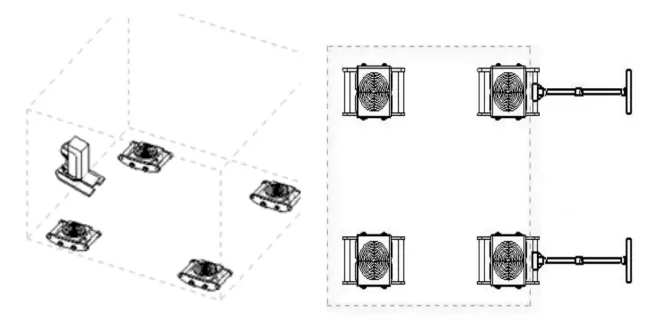

portable magnetic lifter

The versatility of portable magnetic lifters makes them an invaluable asset across various industries. In manufacturing, they are commonly used to lift steel plates, sheets, and blocks. In construction, they can assist in placing heavy structural components or machinery onto site. Even in warehouses, these lifters enhance productivity by allowing quick loading and unloading of metal inventory.

Moreover, portable magnetic lifters are not limited to industrial use. They can also find applications in repair shops, automotive garages, and even in arts and crafts for handling large metal pieces. Their lightweight and portable nature ensure they can be easily transported and utilized in different settings.

Safety and Efficiency

One of the significant advantages of using portable magnetic lifters is their contribution to workplace safety. Traditional methods of lifting heavy objects often involve cranes or hoists, which can pose risks to operators. Magnetic lifters reduce the chance of accidents associated with lifting operations. Since they require less manual handling, the risk of strains and injuries is minimized.

Furthermore, these lifters can significantly increase efficiency. With the ability to lift heavy loads quickly and securely, operations can proceed with greater speed and less downtime. This efficiency can lead to reduced labor costs and improved productivity, making magnetic lifters not just a safe choice but a smart investment as well.

Conclusion

In conclusion, portable magnetic lifters are a testament to how innovative engineering can address modern industrial challenges. Their ability to lift heavy materials safely and efficiently makes them an indispensable tool in various sectors. As industries continue to seek ways to enhance productivity and maintain safety, the popularity and utilization of portable magnetic lifters are likely to increase. By incorporating such tools into daily operations, businesses can achieve a seamless workflow while ensuring the well-being of their workforce. Whether in a bustling factory or a small workshop, the portable magnetic lifter is indeed a game-changer in the world of material handling.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025